Electrode film for electric double-layer capacitor and production method therefor

An electric double layer capacitor and electrode film technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of sheet electrode destruction, sheet electrode powder drop, and changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] Active carbon (YP50F manufactured by Kuraray Chemical Co., Ltd.), conductive carbon (Ketchen blackECP600JD manufactured by Lion Corporation) and PTFE (Polyflon D-1E manufactured by Daikin Industries, Ltd.) were calculated according to the weight of activated carbon: conductive carbon: PTFE = 88:6:6 The ratio is measured so that the total amount is 1.5 kg.

[0117] 370 parts by weight of ion-exchanged water was mixed with a total of 100 parts by weight of these activated carbons, conductive carbons, and PTFE, and stirred at a low speed (140 rpm) for 30 seconds to obtain a kneaded product.

[0118] Then, these kneaded products were rolled once with a calender roll at a roll speed of 1 m / min to a thickness of 520 to 530 μm. Secondary rolling was then performed at a roll speed of 2 m / min to obtain an electrode film with a thickness of 500 μm.

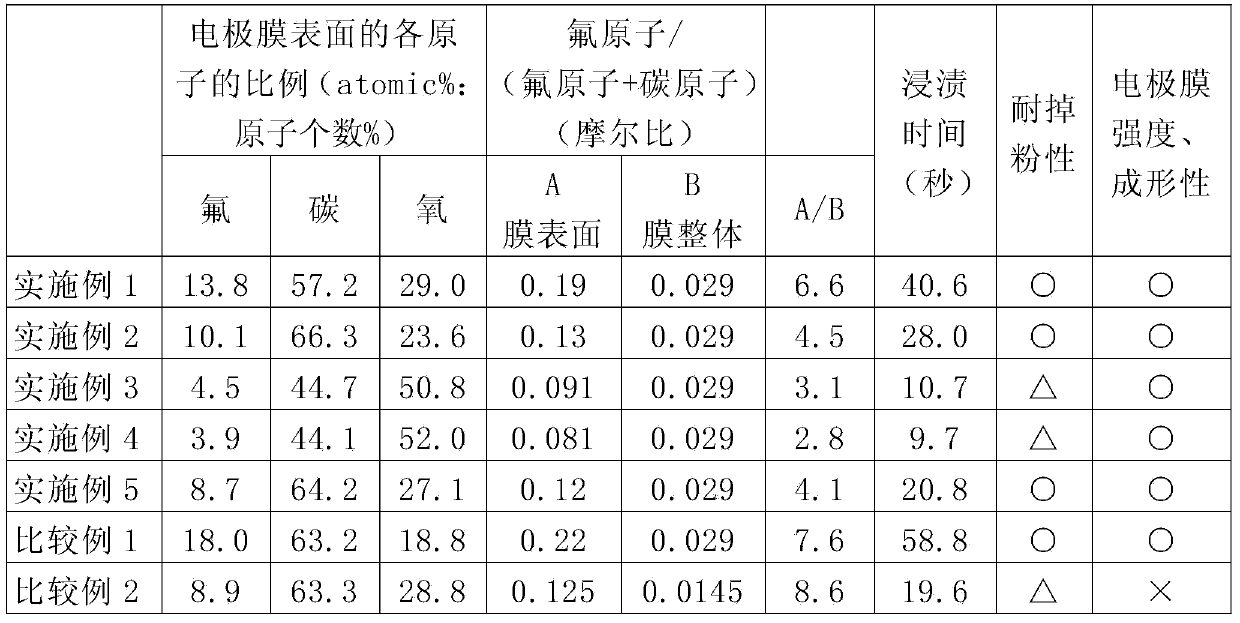

[0119] Table 1 shows the evaluation results of this electrode film.

[0120] In addition, since the electrode film is manufactured ...

Embodiment 2

[0122] Except that the roll speed of the primary rolling was changed from 1 m / min to 0.8 m / min, and the secondary rolling was not performed, the same operation as in Example 1 was performed to obtain an electrode film with a thickness of 500 μm.

[0123] Table 1 shows the evaluation results of this electrode film.

Embodiment 3

[0128] An electrode film was obtained in the same manner as in Comparative Example 1, and then the surface of the electrode film was subjected to plasma treatment under the following conditions to obtain an electrode film.

[0129] (Plasma treatment conditions)

[0130] Gas type: He, gas flow rate: 3L / min, plasma frequency: 5kHz, output: 120W, irradiation time: 300 seconds

[0131] Table 1 shows the evaluation results of this electrode film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com