Solid-liquid connecting method of aluminum materials

A connection method and aluminum technology, which is applied in the field of solid-liquid connection of aluminum materials, can solve problems affecting the performance of interactive connectors, and achieve the effects of avoiding oxidation slag inclusions, small constraints, and simple technical procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

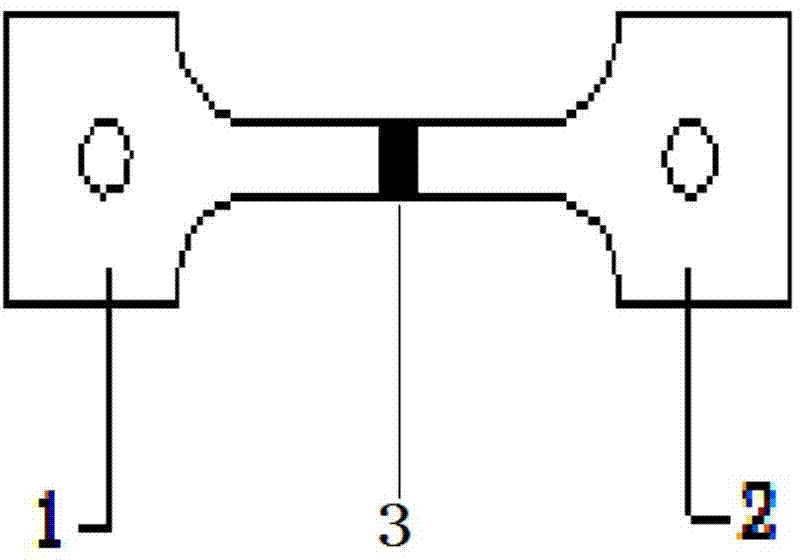

[0037] This embodiment relates to a method for connecting deformed aluminum alloys and cast aluminum alloys, comprising the following steps:

[0038] Step 1. Electrogalvanizing treatment is carried out on the surface of the solid 6101 aluminum alloy (deformed aluminum alloy) preset material to be connected, and the thickness of the galvanized layer is 5 μm;

[0039] Step 2, melting and refining A356 aluminum alloy and (cast aluminum alloy) to be poured;

[0040] Step 3. Presetting the electro-galvanized 6101 aluminum alloy preset material obtained in Step 1 in the mold cavity;

[0041] Step 4, using a metal mold casting method, pouring the A356 aluminum alloy into the cavity of the mold at 700°C. To form a metallurgical bond between two aluminum alloy materials, that is, to complete the solid-liquid connection of dissimilar aluminum alloys.

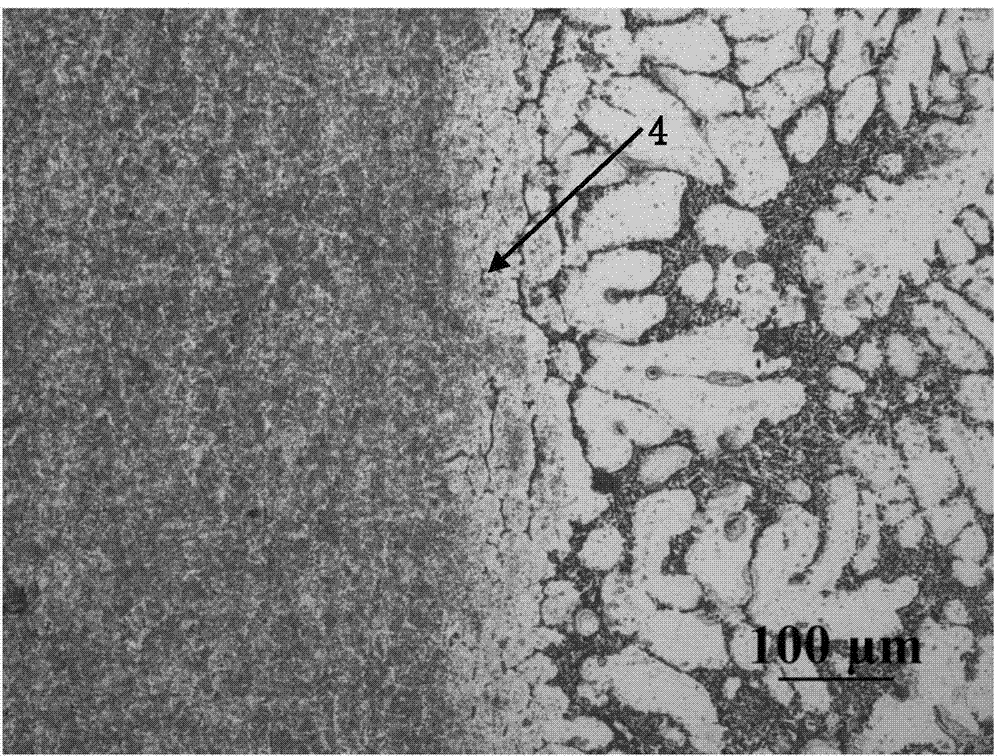

[0042] figure 2 It is the interface area diagram of 6101 aluminum alloy and A356 aluminum alloy after solid-liquid bonding under thi...

Embodiment 2

[0044] This embodiment relates to a method for connecting deformed aluminum alloy and pure aluminum, including the following steps:

[0045] Step 1. Electrogalvanizing treatment is performed on the surface of the solid 6101 aluminum alloy preset material to be connected, and the thickness of the galvanizing layer is 5 μm;

[0046] Step 2, melting and refining the pure aluminum to be poured;

[0047] Step 3. Presetting the electro-galvanized 6101 aluminum alloy preset material obtained in Step 1 in the mold cavity;

[0048] Step 4: Using a squeeze casting method, pour pure aluminum into the cavity of the mold at 700° C., with a squeeze pressure of 20 MPa. To form a metallurgical bond between two aluminum alloy materials, that is, to complete the solid-liquid connection of dissimilar aluminum materials.

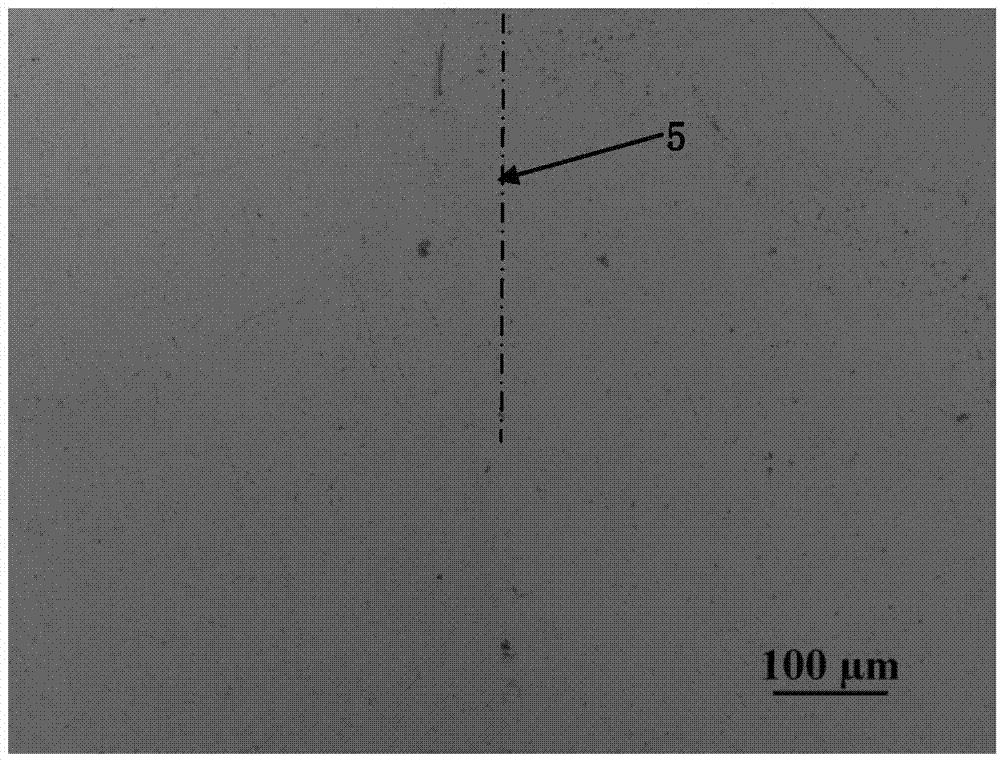

[0049] image 3It is a diagram of the interface area between 6101 aluminum alloy and industrial pure aluminum under this condition. It can be observed from the diagram that ...

Embodiment 3

[0051] This embodiment relates to a method for connecting deformed aluminum alloys and deformed aluminum alloys, including the following steps:

[0052] Step 1. The surface of the solid 6101 aluminum alloy preset material to be connected is subjected to thermal spraying zinc treatment, and the thickness of the zinc layer is 20 μm;

[0053] Step 2, melting and refining the 6101 aluminum alloy to be poured;

[0054] Step 3, presetting the 6101 aluminum alloy preset material obtained in step 1 that has been subjected to thermal spray zinc treatment in the mold cavity;

[0055] Step 4: Using a squeeze casting method, pour 6101 aluminum alloy into the cavity of the mold at 700° C., with a squeeze pressure of 50 MPa. To form a metallurgical bond between two aluminum alloy materials, that is, to complete the solid-liquid connection of the same aluminum alloy.

[0056] Figure 4 It is the interface area diagram of 6101 aluminum alloy and 6101 aluminum alloy under this condition. Un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com