Efficient and lasting smell removal agent master batch, and preparation method and application thereof

A deodorant and masterbatch technology, which is applied in the field of efficient and durable deodorant masterbatch and its preparation, can solve the problems of low deodorant efficiency, performance degradation, and poor durability, and achieve high cost performance, performance degradation, high efficiency and durability , the effect of eliminating bad smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

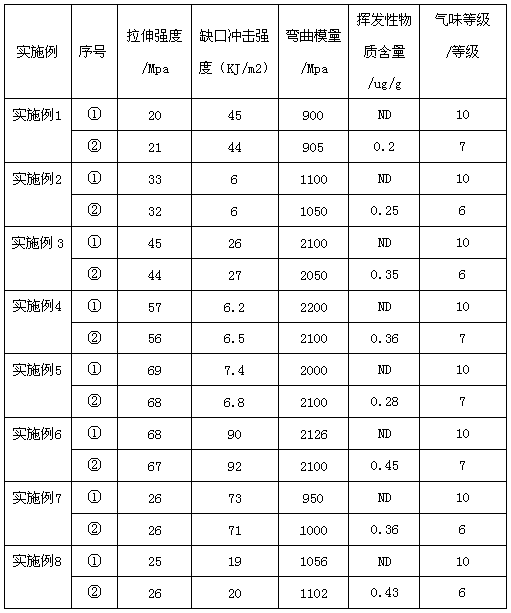

Examples

Embodiment 1

[0036] Weigh 5.0 parts of the adsorbent diatomite and 1 part of the deodorant KHFS-25 according to the weight ratio, put them into a constant temperature high-speed mixer at 100°C, close the top cover, turn on the mixer, adjust the speed to 1000rpm and stir for 5 minutes, that is The activation process can be completed, then close the high mixer, add 0.1 part of antioxidant 1010, 0.1 part of dispersant ethylene bis stearamide, 0.1 part of silane coupling agent KH550, 0.1 part of lubricant white oil, thermoplastic Resin polypropylene is 90 parts, adjust the high speed of the mixer again to 1200rpm, stir for 1min, then put the evenly stirred mixture into the twin-screw extruder, melt and extrude, and then after water cooling, cut into length by pelletizer The particle size is 1-5mm, and the deodorant masterbatch is obtained. Among them, the processing temperature of the extruder is 180°C, 195°C, 200°C, 200°C, 205°C from the feeding port to the die port, the main engine speed is ...

Embodiment 2

[0040] Weigh 30.0 parts of adsorbent activated carbon, 3 parts of deodorant KHFS-25, 6 parts of deodorant XR-2010 and 11 parts of deodorant 851 according to the weight ratio, and put them into a constant temperature high-speed mixer at 120°C , after sealing the upper cover, turn on the mixer, adjust the rotation speed to 1300rpm and stir for 5 minutes to complete the activation process, then turn off the high mixer, add 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, dispersant ethylene 0.3 parts of bis stearamide, 0.3 parts of silane coupling agent KH550, 0.1 parts of lubricant white oil, 50 parts of polypropylene, adjust the high mixer speed to 1000rpm again, stir for 2min, and then add the evenly stirred mixture into the double In the screw extruder, the deodorant masterbatch is obtained by melt extruding, followed by water cooling, and cutting into particles with a length of 1-3mm by a pelletizer. Among them, the processing temperature of the extruder is 180°C...

Embodiment 3

[0044] Weigh 20.0 parts of adsorbent talcum powder, 5 parts of deodorant XR-2010 and 10 parts of deodorant 851 according to the weight ratio, put them into a constant temperature high-speed mixer at 120°C, seal the top cover, and turn on the mixer. Adjust the rotation speed to 1200rpm and stir for 5 minutes to complete the activation process, then turn off the high mixer, add 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.1 part of dispersant ethylene bisstearamide, silane The coupling agent KH550 is 0.3 parts, the lubricant white oil is 0.1 parts, and the ABS is 50 parts. Adjust the high mixer speed again to 1000rpm, stir for 2min, and then put the evenly stirred mixture into the twin-screw extruder, and melt extrude After cooling with water, cut into particles with a length of 1-3mm by a pelletizer to obtain deodorant masterbatches. Among them, the processing temperature of the extruder is 180°C, 200°C, 220°C, 220°C, 210°C from the feeding port to the die port,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com