Method for producing arachidonic acid oil by Mortierella alpina fermentation on basis of dissolved oxygen control

A technology of Mortierella alpine and arachidonic acid, which is applied in the field of microbial fermentation, can solve problems such as rise, and achieve the effects of simple process operation, improved fermentation capacity, and good profit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

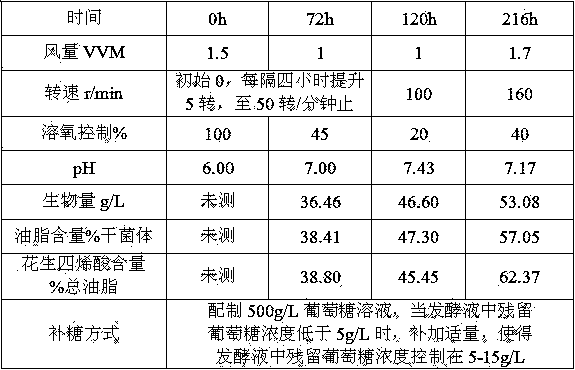

[0030] Example 1 Fermentation of Mortierella alpina in a 7.5L tank to produce arachidonic acid oil based on dissolved oxygen control strategy

[0031] 1. Activation of strains and preparation of seed solution: Mortierella alpina strain R807 (CCTCC M 2012118) was selected as the starting strain, and the preserved strains were inserted into PDA slant medium, and placed in an incubator at 25°C Cultivate for 10 days, transfer to a 500mL grooved bottle containing 100mL seed medium and culture in a constant temperature shaker, the inoculum size is 10% (v / v, 10mL), the culture conditions are 120rpm, the temperature is 25°C, and the culture time is 1 -2 days.

[0032] 2. Inoculate the seed liquid obtained in step 1 into a 7.5L tank (New Brunswick Scientific, USA), the liquid volume is 5L, the inoculum volume is 10% (v / v, 500mL), and the culture temperature is controlled at 28°C for 0-120h , 121-216h controlled at 18°C,

[0033]At the beginning of fermentation, the seed li...

Embodiment 2

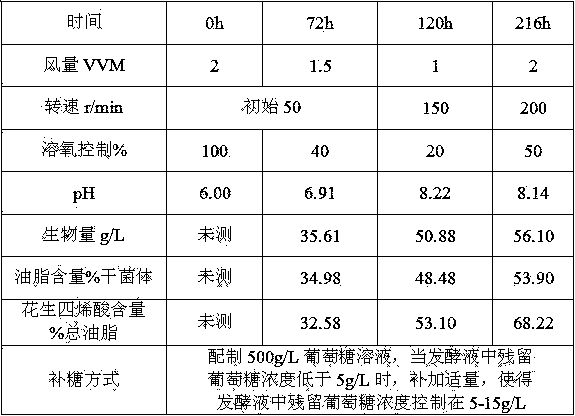

[0041] Example 2. Arachidonic acid produced by fermenting Mortierella alpina in a 7m3 tank based on the dissolved oxygen regulation strategy

[0042] 1. Activation of strains and preparation of seed solution: Mortierella alpina strain R807 (CCTCC M 2012118) was selected as the starting strain, and the preserved strains were inserted into PDA slant medium, and placed in an incubator at 25°C Cultivate for 10 days, transfer to a 500mL grooved bottle containing 100mL seed medium and culture in a constant temperature shaker, the inoculum size is 10% (v / v, 10mL), the culture conditions are 120rpm, the temperature is 25°C, and the culture time is 1 -2 days, prepare a first-grade seed solution. Then, according to the inoculation amount of 10% (v / v), the primary seed solution was inserted into a 100L seed tank, the cultivation conditions were 200 rpm, the temperature was 25°C, and the cultivation time was 1 day to prepare the secondary seed solution. Next, all the prepared seco...

Embodiment 3

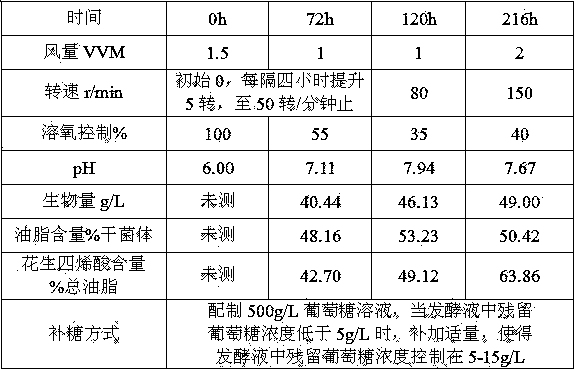

[0051] Example 3. Arachidonic acid produced by fermenting Mortierella alpina in a 25m3 tank based on the dissolved oxygen regulation strategy

[0052] 1. Activation of strains and preparation of seed solution: Mortierella alpina strain R807 (CCTCC M 2012118) was selected as the starting strain, and the preserved strains were inserted into PDA slant medium, and placed in an incubator at 25°C Cultivate for 10 days, transfer to a 500mL grooved bottle containing 100mL seed medium and culture in a constant temperature shaker, the inoculum size is 10% (v / v, 10mL), the culture conditions are 120rpm, the temperature is 25°C, and the culture time is 1 -2 days, prepare a first-grade seed solution. Then, according to the inoculation amount of 10% (v / v), the primary seed solution was inserted into a 150L seed tank, the cultivation conditions were 200rpm, the temperature was 25°C, and the cultivation time was 1 day to prepare the secondary seed solution. Next, all the prepared sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com