Six-element fiber yarn compounding technology

A composite technology and fiber technology, which is applied in the field of six-component fiber yarn composite technology, can solve problems such as poor renewal ability, low technical content, and few varieties, and achieve the effects of reducing production costs, obvious economic benefits, and stable yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention is further illustrated below by way of examples.

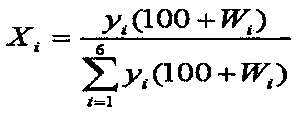

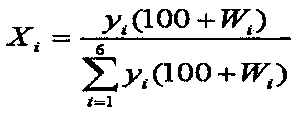

[0015] Take 1KG of lules rainbow fiber, 7KG of light flat blue fiber, 2KG of light flat purple fiber, 5KG of light black polyester conductive fiber, 25KG of viscose fiber, and 60KG of cotton fiber. Effectively mix in the cotton blender, open the cotton opener to remove impurities from the raw cotton, and then further remove impurities, then enter the cotton box machine, continue to mix, open the cotton block, enter the lapping machine, and make cotton laps; cotton laps Enter the carding machine, separate the single fiber state, enter the drawing frame, the cotton sliver is mixed and drawn, and then enter the roving frame to make thick yarn, then enter the spinning frame, wind into single yarn, and automatically wind into a package .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com