Preparation method of nylon composite material

A nylon composite material, nylon technology, applied in the nylon field, can solve the problems of poor thermal stability, impact resistance needs to be improved, etc., and achieve the effects of good compatibility, excellent aging resistance, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

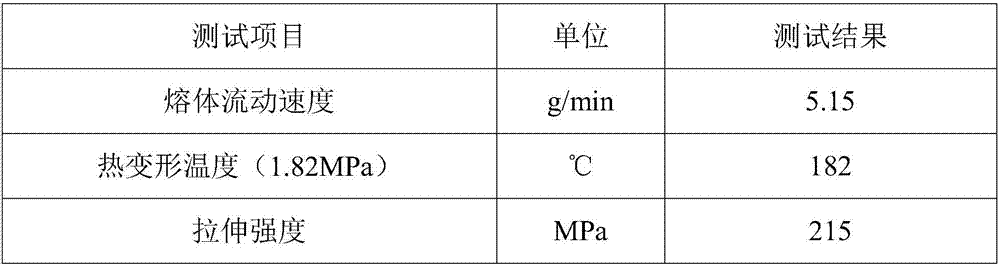

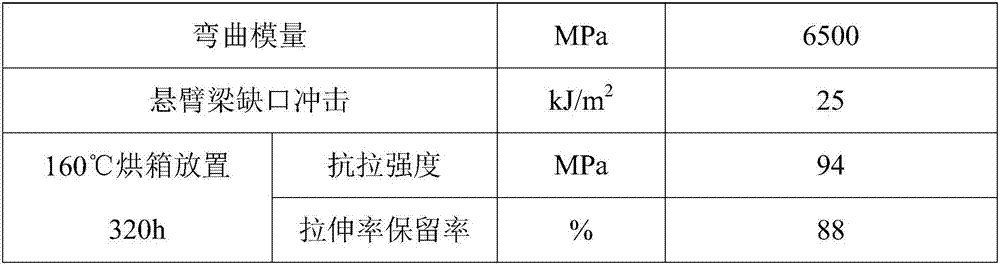

Examples

Embodiment 1

[0014] The preparation method of a kind of nylon composite material that the present invention proposes, comprises the following steps: add nylon PA66, epoxy resin E-51, maleic anhydride polyolefin elastomer, polyvinyl alcohol into high-speed mixer, drop into dilauric acid Dibutyltin, chlorinated paraffin, mix, add succinic anhydride complex, coupling agent KH550 and continue to stir, add medium alkali glass fiber, magnesium hydroxide, aluminum hydroxide, ammonium polyphosphate, antioxidant, lubricant and continue to stir, then Add it into a twin-screw extruder, mix evenly, melt and extrude, and cool to obtain a nylon composite material.

Embodiment 2

[0016] The preparation method of a kind of nylon composite material that the present invention proposes comprises the following steps: comprising the following steps: adding nylon PA66, epoxy resin E-51, maleic anhydride polyolefin elastomer, polyvinyl alcohol into a high-speed mixer, dripping Add dibutyltin dilaurate, chlorinated paraffin, mix for 20 minutes, add succinic anhydride complex, coupling agent KH550 and continue stirring for 15 minutes, add medium alkali glass fiber, magnesium hydroxide, aluminum hydroxide, ammonium polyphosphate, antioxidant, Continue to stir the lubricant for 15 minutes, then add it to the twin-screw extruder and mix evenly, melt and extrude, the extrusion temperature is 265°C, the twin-screw aspect ratio is 47, the host speed is 485r / min, and the nylon composite material is obtained after cooling.

[0017] The succinic anhydride complex is prepared by the following process: mix succinic anhydride and acetone evenly, add 4-dimethylaminopyridine a...

Embodiment 3

[0019] A kind of preparation method of nylon composite material that the present invention proposes, comprises the steps: by weight 40 parts of nylon PA66, 40 parts of epoxy resin E-51, 15 parts of maleic anhydride polyolefin elastomers, 30 parts of polyvinyl alcohol Add a high-speed mixer, drop 1 part of dibutyltin dilaurate, 2 parts of chlorinated paraffin, mix for 15 minutes, add 2 parts of succinic anhydride complex, 1 part of coupling agent KH550 and continue stirring for 20 minutes, add 10 parts of medium-alkali glass fiber , 4 parts of magnesium hydroxide, 1 part of aluminum hydroxide, 3 parts of ammonium polyphosphate, 1 part of antioxidant, 2 parts of lubricant and continue to stir for 10 minutes, then add to the twin-screw extruder and mix evenly, melt extrude, extrude The temperature is 280°C, the aspect ratio of the twin-screw is 45, the rotation speed of the main engine is 500r / min, and the nylon composite material is obtained by cooling.

[0020] The succinic anh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com