Method for achieving holographic waveguide grating large exit pupil

A holographic waveguide and grating technology, applied in the field of holographic waveguide grating, can solve the problems of energy loss and low diffraction efficiency of holographic grating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

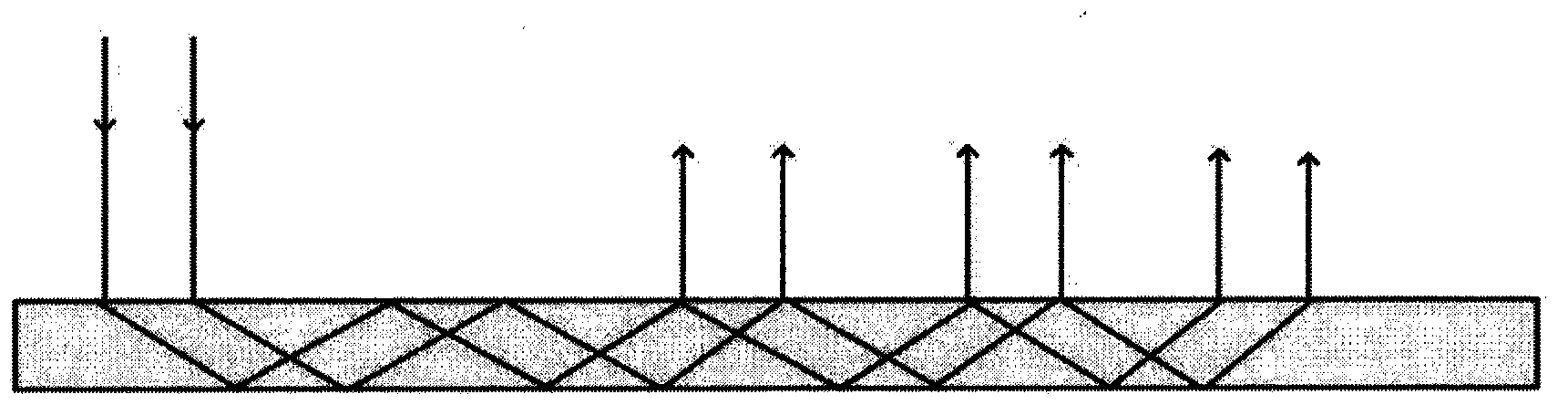

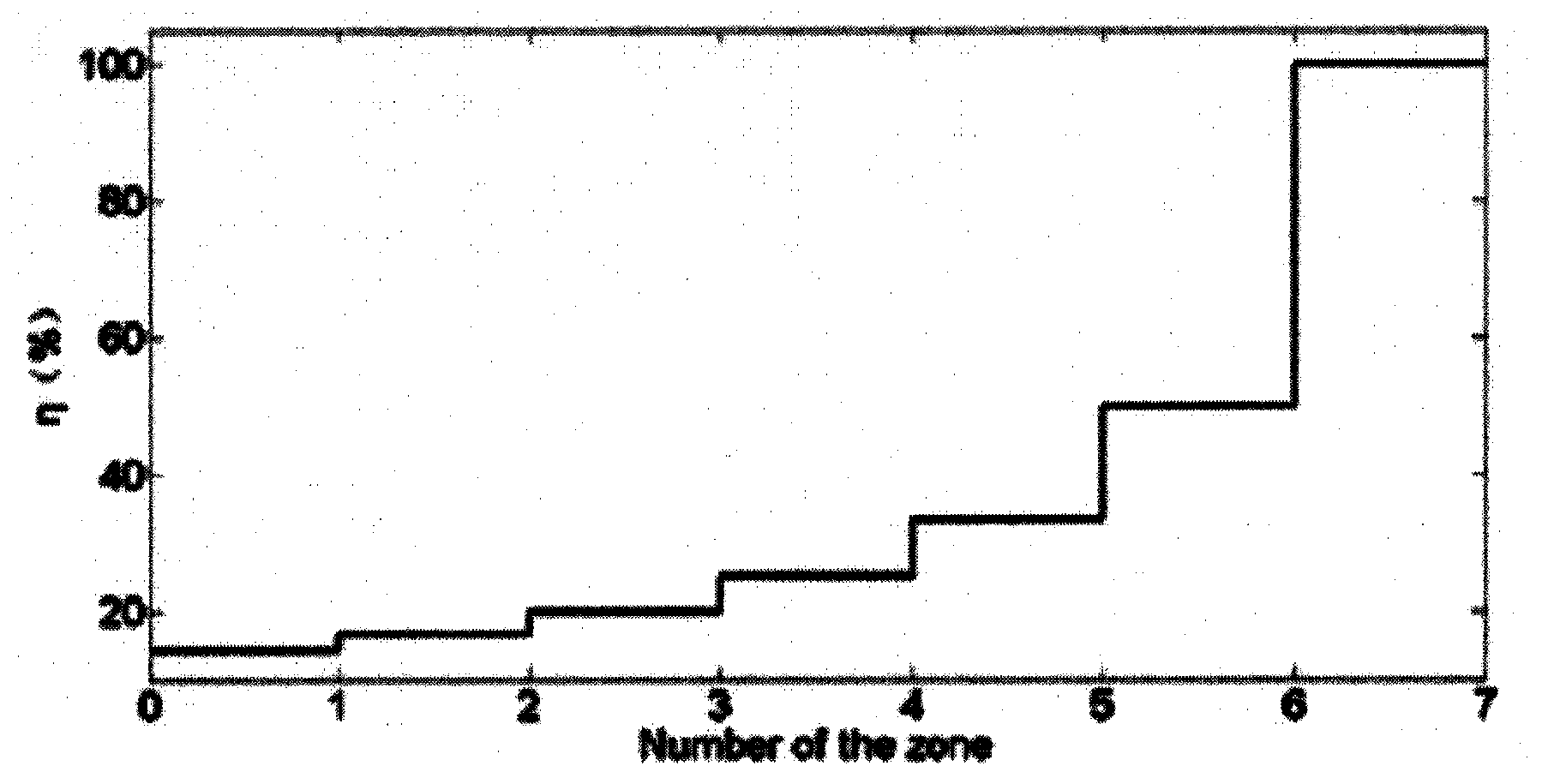

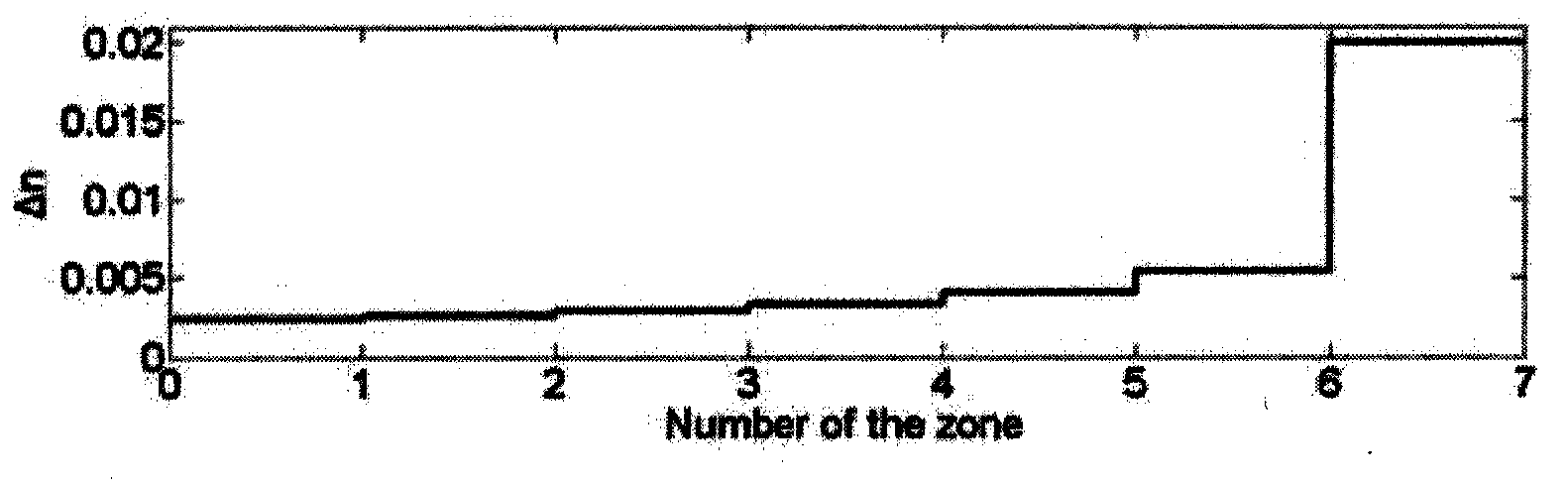

[0036] The method for realizing the large exit pupil of the holographic waveguide grating disclosed in this embodiment is realized by the micro display part, the collimating lens part and the holographic waveguide grating part, and the interference modulation method is used to modulate different lights in different regions on a designated plane. The strong light wave interferes with another plane wave, and the same grating with different diffraction efficiency can be fabricated at the same time, so as to realize the uniform diffraction and output of the light wave, and then realize the large exit pupil of the holographic waveguide grating.

[0037] like figure 1 As shown, in order to make the holographic waveguide grating have the property of a large exit pupil, the main problem is to make the light intensity of the multiple total reflection coupling and output uniform, so that the diffraction efficiency of each coupling output needs to be different. With the fabrication metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com