Packaging shell based on LCP substrate and preparation method thereof

A technology for encapsulating shells and substrates, which is used in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices. Achieve the effect of light weight, better protection, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific drawings and embodiments.

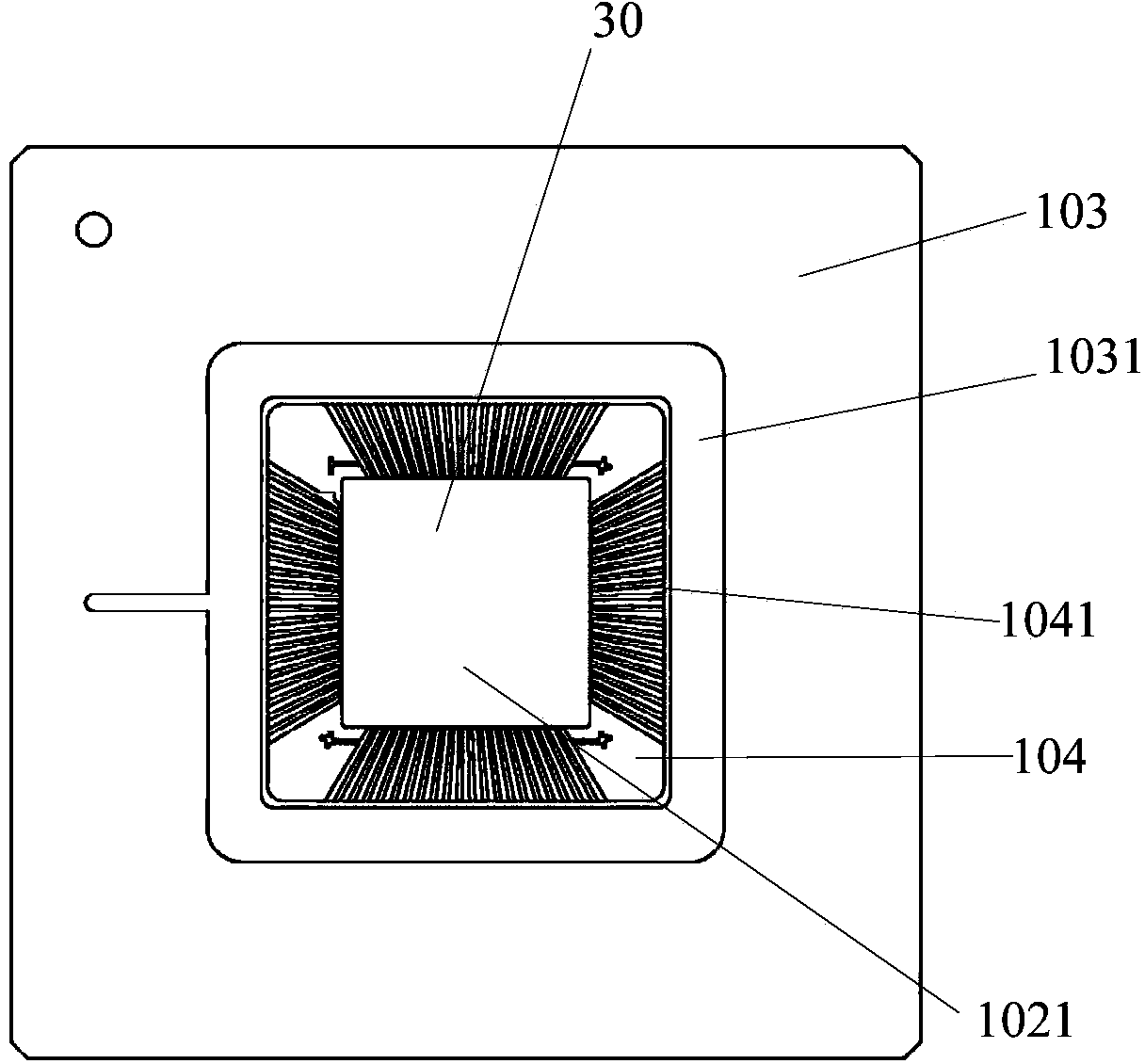

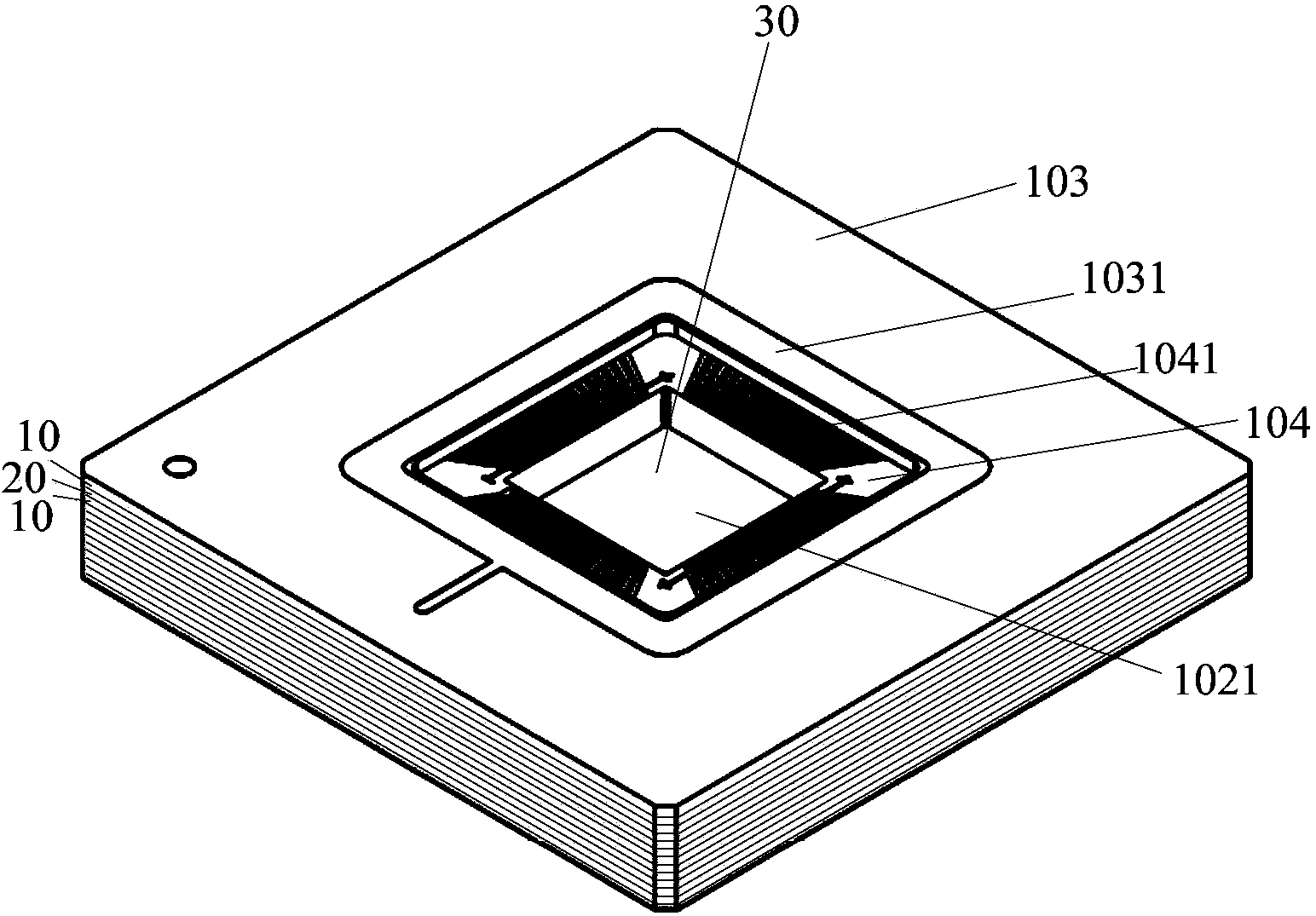

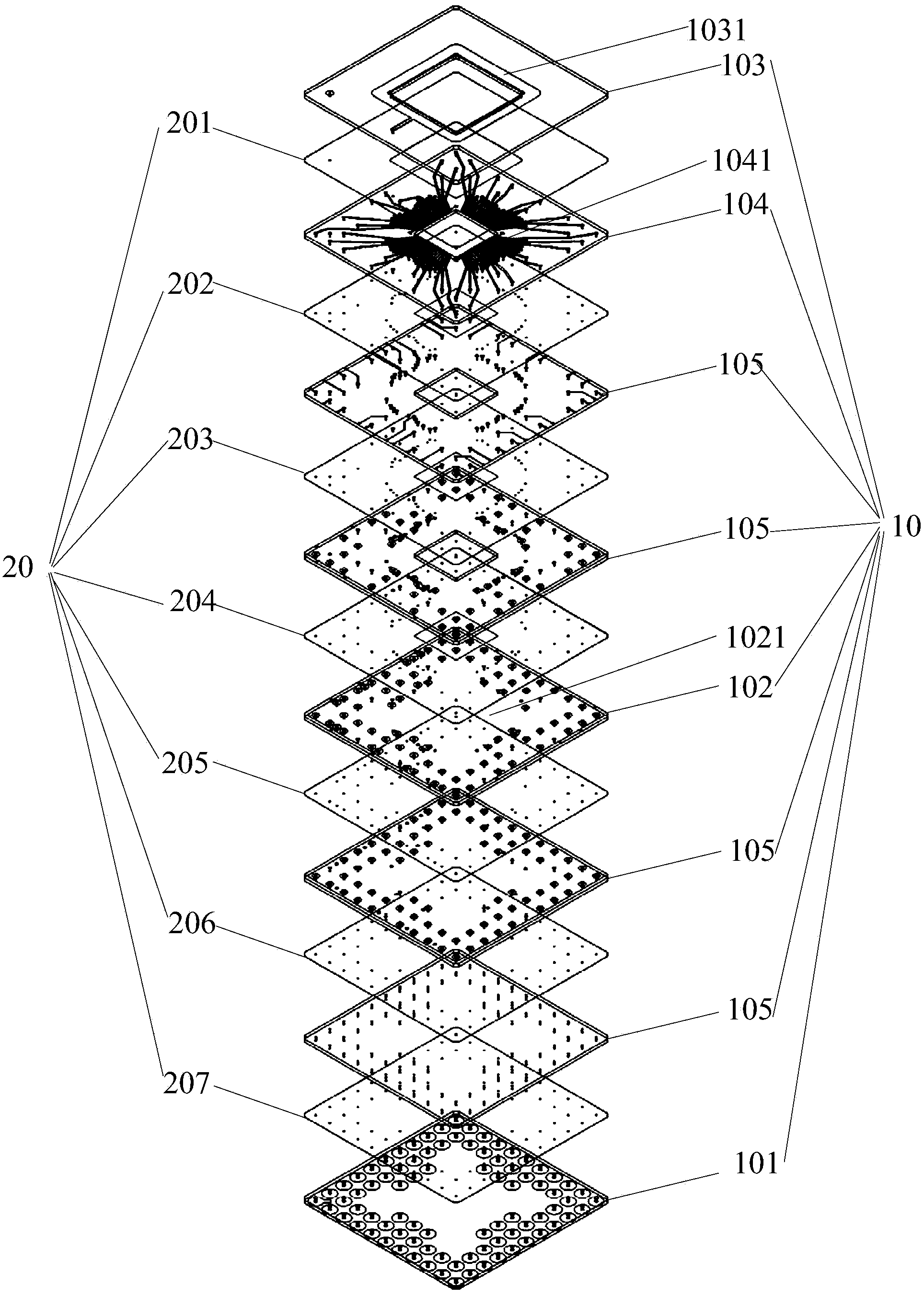

[0036] Such as figure 1 , Figure 2, image 3 Shown:

[0037] The present invention provides an LCP substrate packaging shell with a cavity structure. LCP, or Liquid Crystal Polymer, is a polymer with outstanding properties.

[0038] Such as Figure 1 ~ Figure 3 As shown, the package housing based on the LCP substrate includes a laminated structure formed by lamination of multiple LCP substrate composition layers 10; adjacent LCP substrate composition layers 10 are combined by each intermediate adhesive layer 20; wherein, each LCP substrate The composition layer 10 is made of an LCP single-layer copper-clad substrate. Each intermediate adhesive layer 20 is made of an LCP film substrate.

[0039] The LCP substrate composition layer 10 includes a bottom pad layer 101 located at the bottom of the laminate structure, a chip mounting layer 102 located in the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com