Traction converter and railway vehicle

A power conversion device and power conversion circuit technology, which is applied in the modification of power electronics, output power conversion devices, electric locomotives, etc., can solve the problems of increasing the number of sheets, the weight of the cooler, and the inability to achieve uniform temperature, etc., to achieve uniform temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

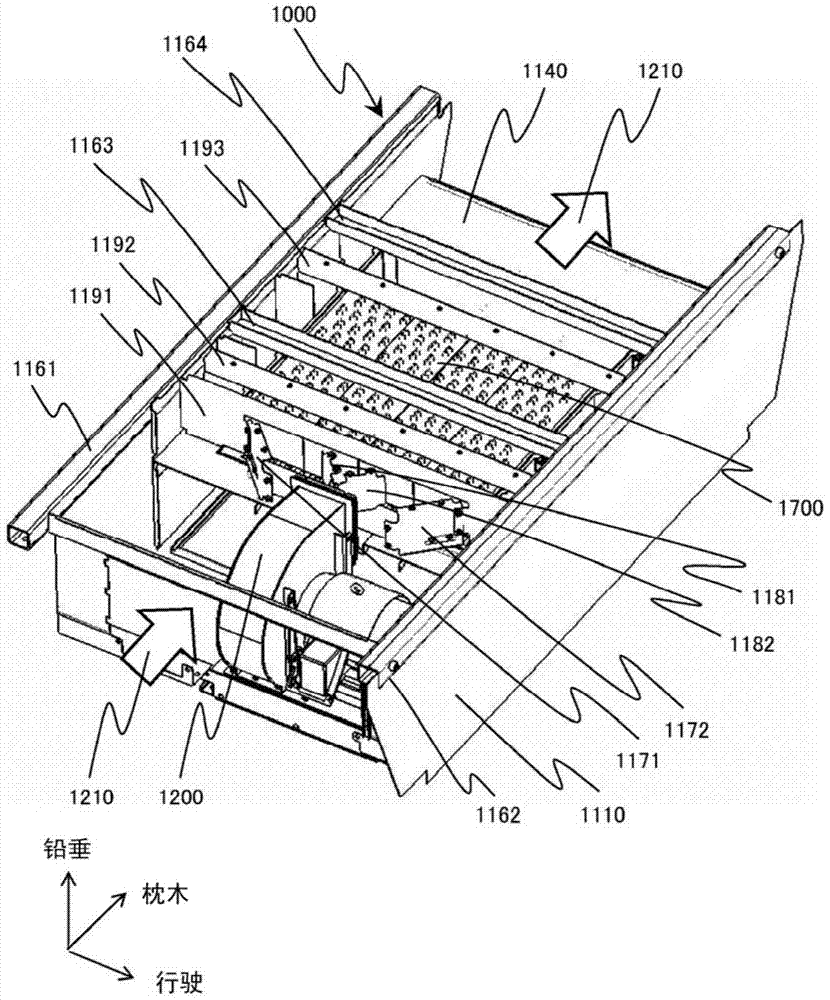

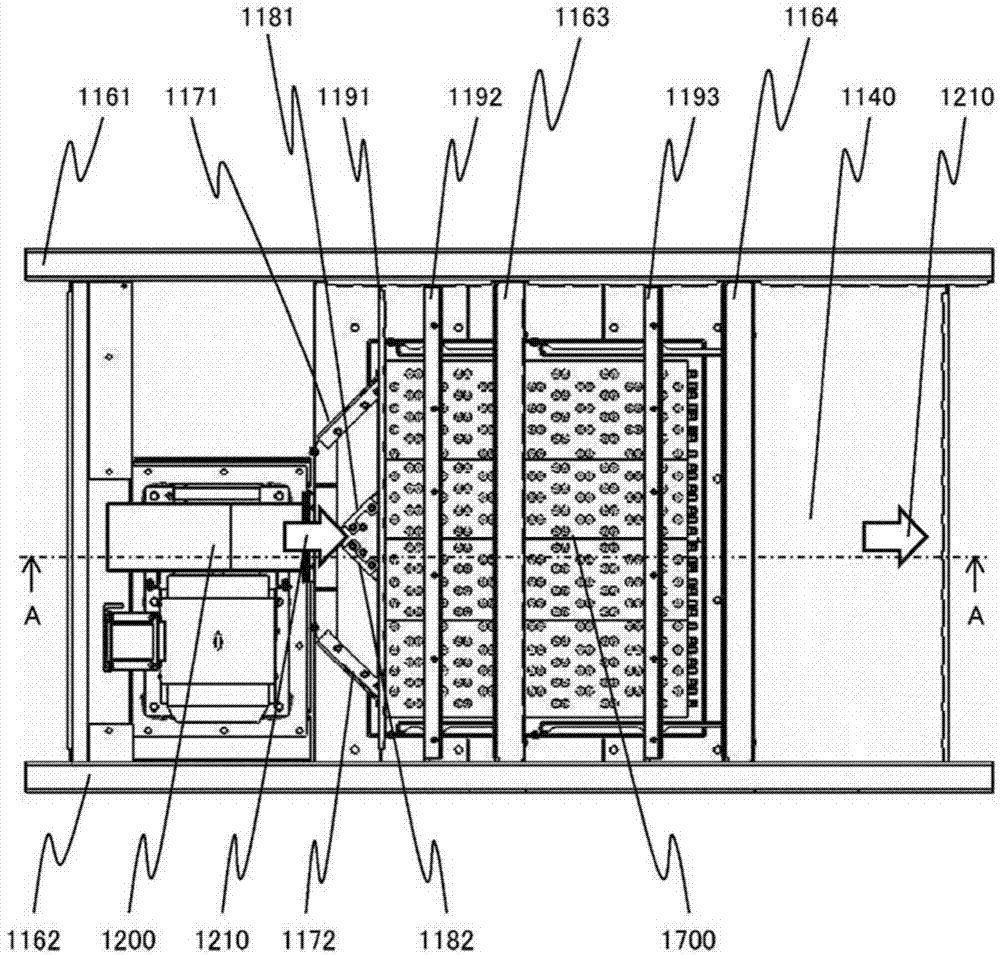

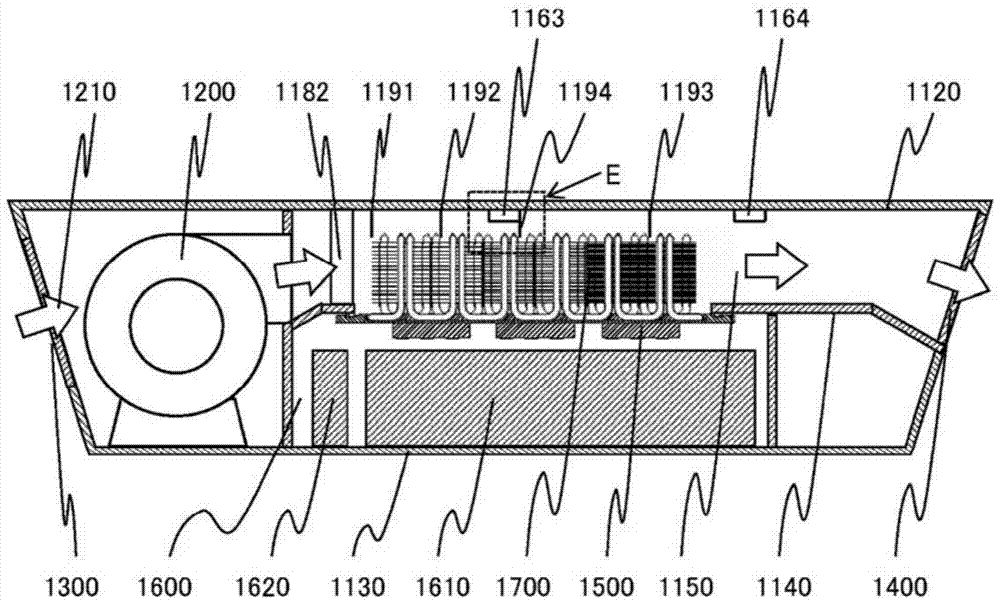

[0095] Hereinafter, the power conversion device of the present invention will be described in detail with reference to the drawings. figure 1 is a perspective view showing the overall configuration of the power conversion device according to the first embodiment of the present invention, figure 2 express figure 1 top view of image 3 express figure 2 A-A cutaway view.

[0096] The power conversion device 1000 is composed of a side plate 1110 , a top plate 1120 , and a bottom plate 1130 . In addition, sleeper direction beams 1161 and 1162 and travel direction beams 1163 and 1164 are provided on the upper surface of the power conversion device 1000 to secure the strength of the power conversion device 1000 . Between the top plate 1120 and the bottom plate 1130 is provided a ventilation path bottom plate 1140 . The space surrounded by the side plate 1110 , the top plate 1120 , and the ventilation path bottom plate 1140 is the ventilation path 1150 , and the cooling air 121...

Embodiment 2

[0123] Figure 14 It is a side cross-sectional view showing a cooler mounted on a power conversion device according to a second embodiment of the present invention. In the first embodiment, the position of the split point of the cooling fins in the cooling air flow direction is fixed, and the number of fins is changed to change the surface areas of the fins in the upwind area 1752, the midstream area 1753, and the downwind area 1754. The surface area of the fins can be changed by changing the position of the split point of the fins in the cooling air flow direction. In the second embodiment, the number of fins 1750 is 12, 24, and 48 from the windward side, the pitch ratio of the fins is 4:2:1, and the surface area of the fins 1750 in the upwind region 1752 is It is 0.35 times of the surface area of the cooling fins 1750 in the downwind area 1754, and the surface area of the cooling fins 1750 in the midstream area 1753 is 0.53 times of the surface area of the cooling...

Embodiment 3

[0127] Figure 16 It is a side cross-sectional view showing a cooler mounted on a power conversion device according to a third embodiment of the present invention. In the third embodiment, two semiconductor element groups 1500 are provided in the cooling air flow direction, and the area where a plurality of cooling fins are provided is divided into two, an upwind area 1752 and a downwind area 1754, along the cooling air flow direction. The number of cooling fins 1750 is 26 in the upwind area 1752 and 48 in the downwind area 1754 . That is, the surface area of the cooling fins 1750 in the upwind region 1752 is 0.54 times the surface area of the cooling fins 1750 in the downwind region 1754 .

[0128] In the structure in which two semiconductor element groups 1500 are installed in the cooling air flow direction as in the third embodiment of the present invention, the plurality of cooling fins 1750 are divided into two parts along the cooling air flow direction, and the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com