Polishing composition, polishing method using same, and method for producing substrate

一种制造方法、组合物的技术,应用在氧化硅层的研磨对象物领域,能够解决易沉降保存稳定性、氧化铈磨粒昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] One embodiment of the present invention will be described below.

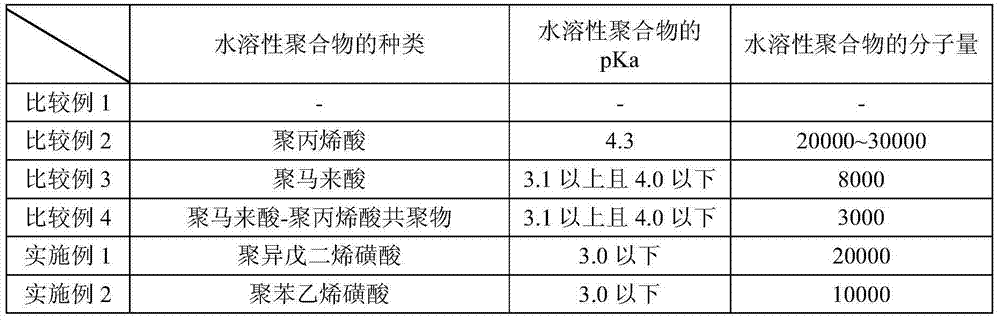

[0021] The polishing composition of the present embodiment is prepared by mixing a water-soluble polymer and abrasive grains in water. Therefore, the polishing composition contains a water-soluble polymer and abrasive grains.

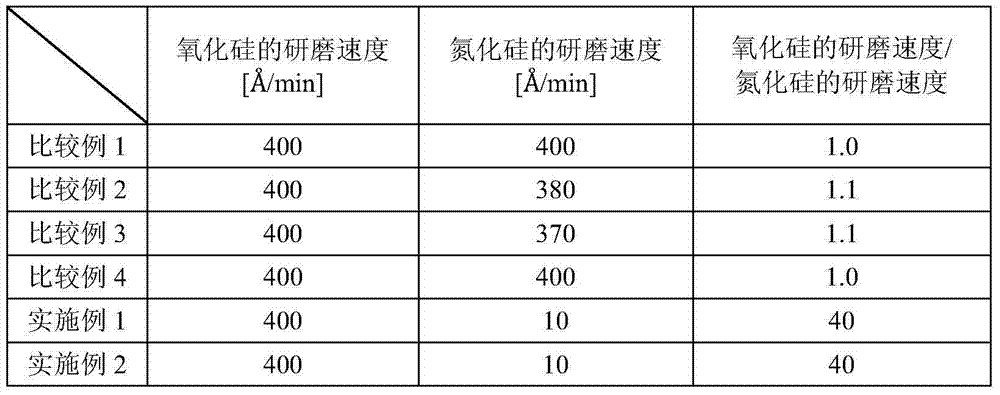

[0022] The polishing composition of the present embodiment is used for polishing an object to be polished having a silicon nitride layer and a silicon oxide layer directly disposed on the silicon nitride layer, and in other words, is used to polish the object to be polished to produce a substrate the use of. The silicon nitride layer exhibits a positive zeta potential below pH 3.5.

[0023] The polishing composition of the present embodiment is not particularly intended to be used for such applications of polishing metals, and therefore does not contain components such as oxidizing agents and metal anti-corrosion agents generally contained in metal polishing compositions.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com