Method for synchronously producing natural soybean cream and polypeptide by adopting aqueous enzymatic method

A water enzymatic method, soybean technology, applied in the field of extraction and processing of vegetable oil and protein, can solve problems such as environmental pollution, protein denaturation, toxic and harmful solvent residues, etc., and achieve the effect of simple process and equipment, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

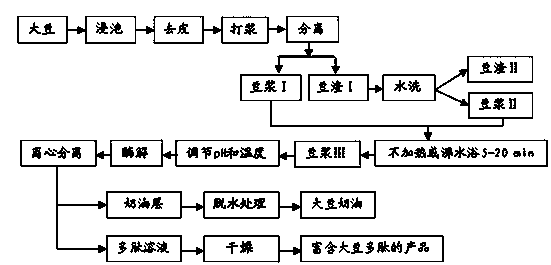

[0035] Soak 200g of soybeans for 18 hours, peel them, add water to a total weight of 2000g, beat with a mixer at room temperature, the stirring speed is 15000rpm, the beating time is 7min, the slurry is filtered to remove slag, and obtain soybean milk I and bean dregs I, and bean dregs I are 1: 3 Add water and stir to mix, leaching for 2 hours, and then filter to obtain soybean milk II and soybean dregs II, mix the above obtained soybean milk I and soybean milk liquid II, and put them in a boiling water bath for 10 minutes to obtain soybean milk III;

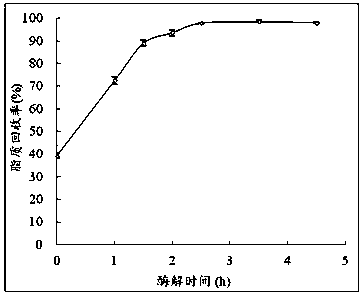

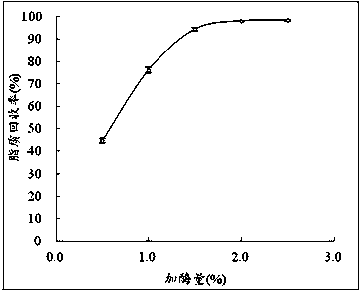

[0036]Soymilk III was injected into the enzymolysis tank, the temperature was adjusted to 50°C, the pH value was adjusted to 8.0 with 6M sodium hydroxide solution, and the temperature was kept constant for 15 minutes. When the pH of the solution no longer changes, add alkaline protease for enzymolysis. Enzymolysis conditions: add enzyme 2% (protease is 2% of the solid content of soybean milk III), stirring speed 100 rpm, enzymoly...

Embodiment 2

[0038] 200 g of soybeans were soaked at 60-70° C. for 2-3 hours, and then peeled off. The following process was the same as in Example 1.

Embodiment 3

[0040] The specific process is the same as in Example 1, except that the mixing with the bean dregs I washing solution (soymilk II) is omitted, and only the soymilk I is hydrolyzed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com