Purification and deodorizing device

A technology for treating layers and intermediate boxes, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of less treatable gas, large energy consumption, and large equipment, and achieves simple and reliable structure and energy consumption. Low, low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

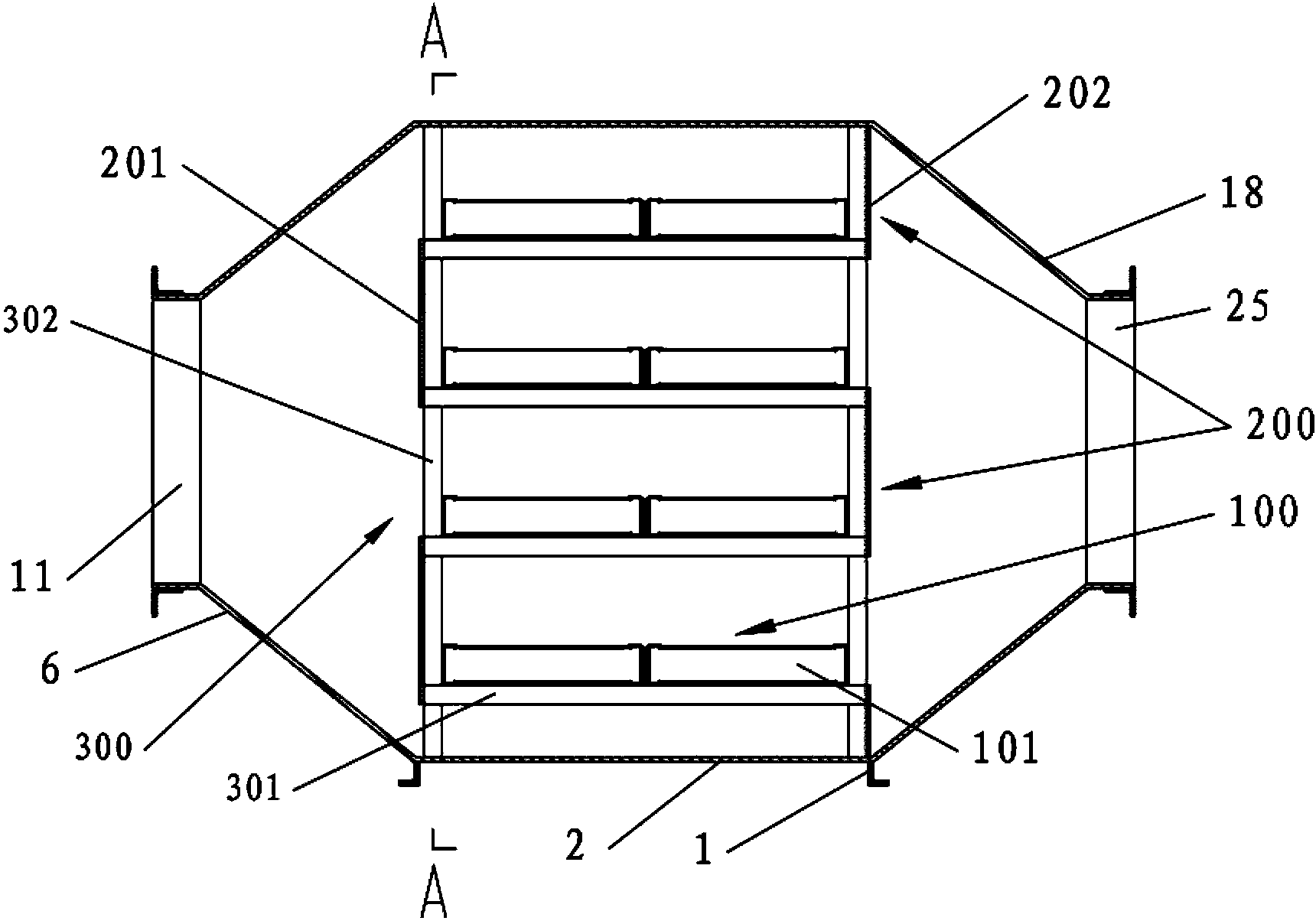

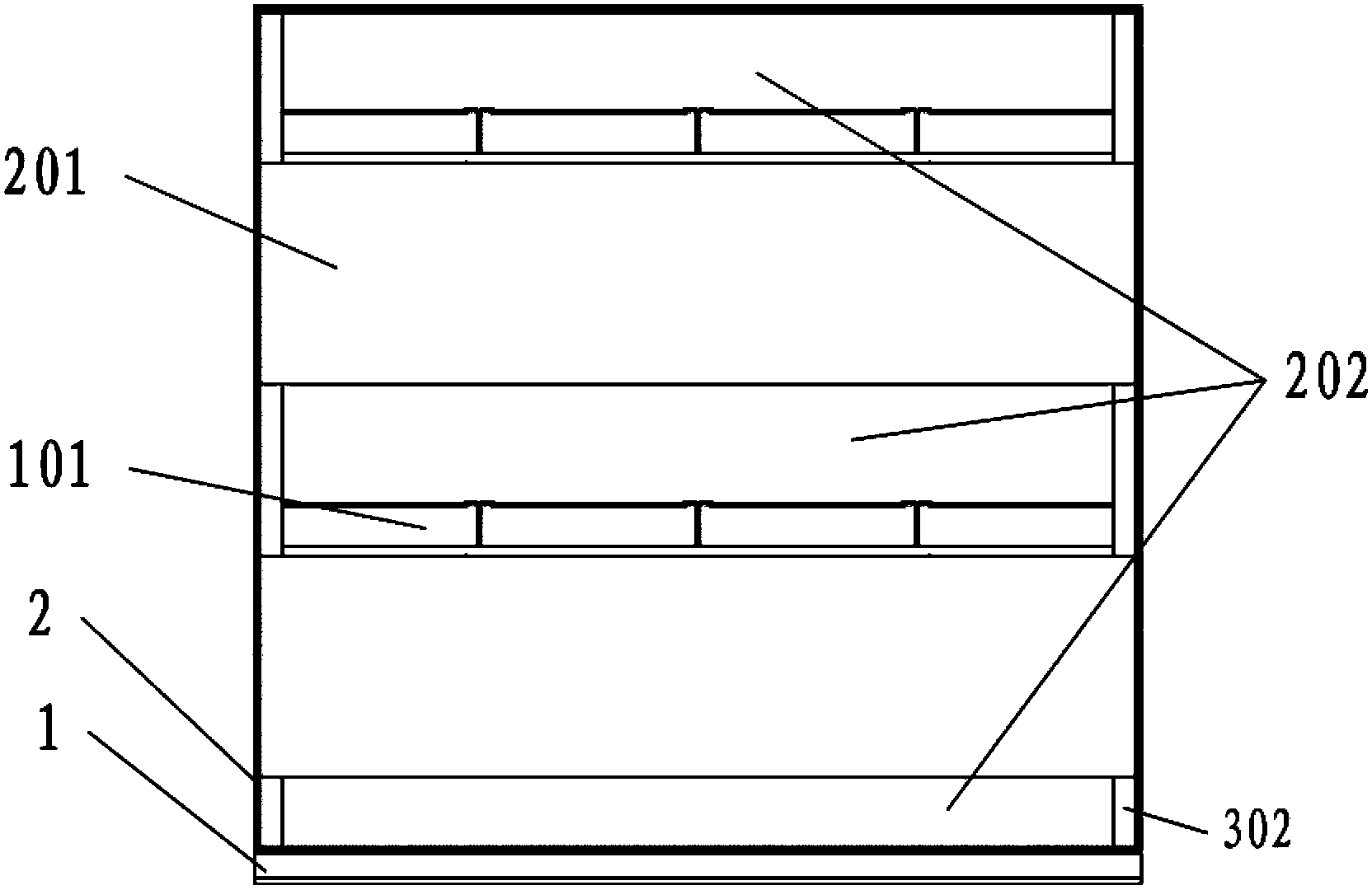

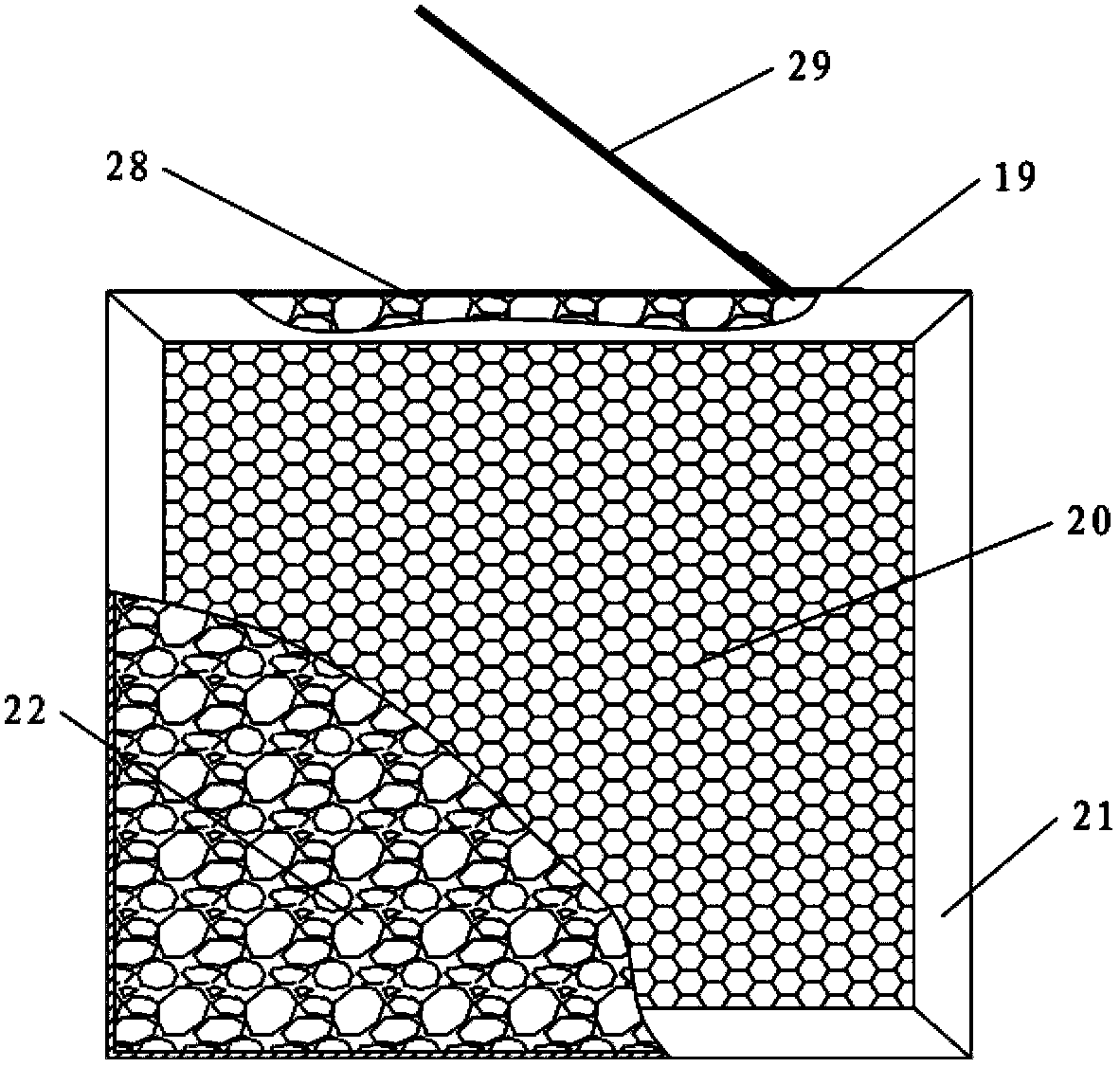

[0049] Such as Figure 5 As shown, this embodiment is used to process 30000m 3 / h cubic meter of rare earth molecular sieve particle bed purification and deodorization device containing toxic and harmful gases, the overall dimensions are: length × width × height = 2400mm × 2000mm × 1800mm. The middle box body 2 is a rectangular box body welded from left to right by steel plates; two L-shaped component legs 1 folded from steel plates are welded on the lower side of the bottom plate to support the entire equipment, and the four corners of the bottom plate of the middle box body 2 are welded and adsorbed. The bracket 300, the adsorption bracket 300 has four layers, and the corresponding processing layer 100 is also four. The adsorption support 300 is composed of four ring frames 301 and a plurality of uprights 302, specifically as follows: one layer of uprights 3 is welded on the upper side of the bottom plate of the middle box 2, and the bottom four corners of one layer of ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com