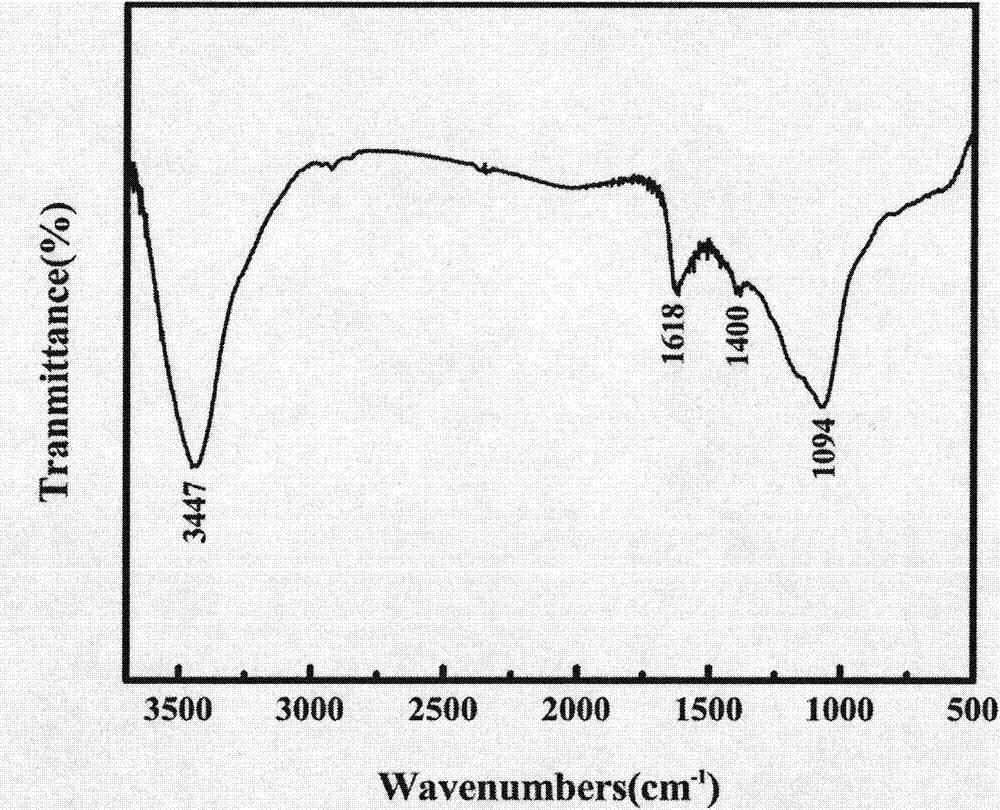

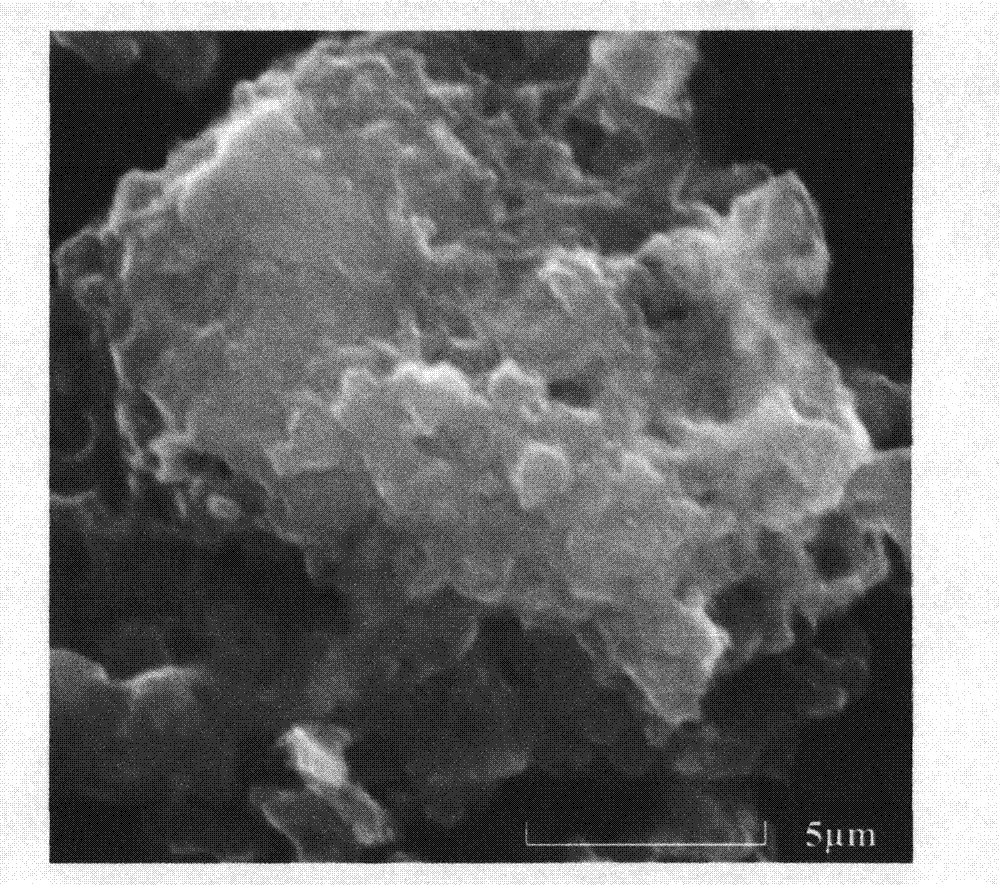

Method for preparing stone coal based mesoporous activated carbon with high specific surface area

A high specific surface area, activated carbon technology, applied in the field of activated carbon preparation, can solve the problems of complicated preparation process steps, low methylene blue adsorption value, and no high-efficiency utilization, and achieve the effects of environmental friendliness, low production cost, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of stone coal-based mesoporous activated carbon with high specific surface area, the concrete steps are as follows:

[0023] (1) Deashing of stone coal raw materials

[0024] Pulverize the stone coal to below 200 mesh (0.074mm), and prepare the pickling solution according to the ratio of hydrofluoric acid volume (ml): concentrated sulfuric acid volume (ml): distilled water volume (ml) ratio of 1:2:85, to The ratio of the mass of stone coal (g) to the volume of acid leaching solution (ml) is 1:12 and mixed, placed in a 400ml reaction vessel, stirred at a constant temperature of 80°C for 2 hours, suction filtered, washed, and dried to obtain deashed of stone coal.

[0025] (2) Preparation of activated carbon crude product

[0026] After the first step (1) is completed, it is placed in the muffle furnace according to the ratio of delimed stone coal mass (g): potassium hydroxide mass (g) of 1: 4, with 100ml min -1 Access to N 2 gas, then at 10°C·min...

Embodiment 2

[0030] A kind of preparation method of stone coal-based mesoporous active carbon of high specific surface area, with embodiment 1, wherein:

[0031] In the (1) step, hydrofluoric acid volume (ml): concentrated sulfuric acid volume (ml): the ratio of distilled water volume (ml) is 1: 3: 80, stone coal quality (g): pickling solution volume (ml) The ratio is 1:6, the stirring temperature is 75°C, and the stirring time is 1h.

[0032] In step (2), the ratio of the mass of delimed stone coal (g): the mass of potassium hydroxide (g) is 1:2, the activation temperature is 850° C., and the activation is performed for 2.0 h.

[0033] In step (3), ultrasonic-assisted pickling was carried out for 20 minutes, the activated carbon was boiled in hot water for 20 minutes, and the boiling was repeated once.

Embodiment 3

[0035] A kind of preparation method of stone coal-based mesoporous active carbon of high specific surface area, with embodiment 1, wherein:

[0036] In the (1) step, hydrofluoric acid volume (ml): concentrated sulfuric acid volume (ml): the ratio of distilled water volume (ml) is 1: 4: 75, stone coal quality (g): pickling solution volume (ml) The ratio is 1:18, the stirring temperature is 90°C, and the stirring time is 3h.

[0037] In step (2), the ratio of the mass of delimed stone coal (g): the mass of potassium hydroxide (g) is 1:3, the activation temperature is 750° C., and the activation is performed for 1.5 h.

[0038] In step (3), ultrasonic-assisted pickling was carried out for 25 minutes, the activated carbon was boiled in hot water for 15 minutes, and the boiling was repeated twice.

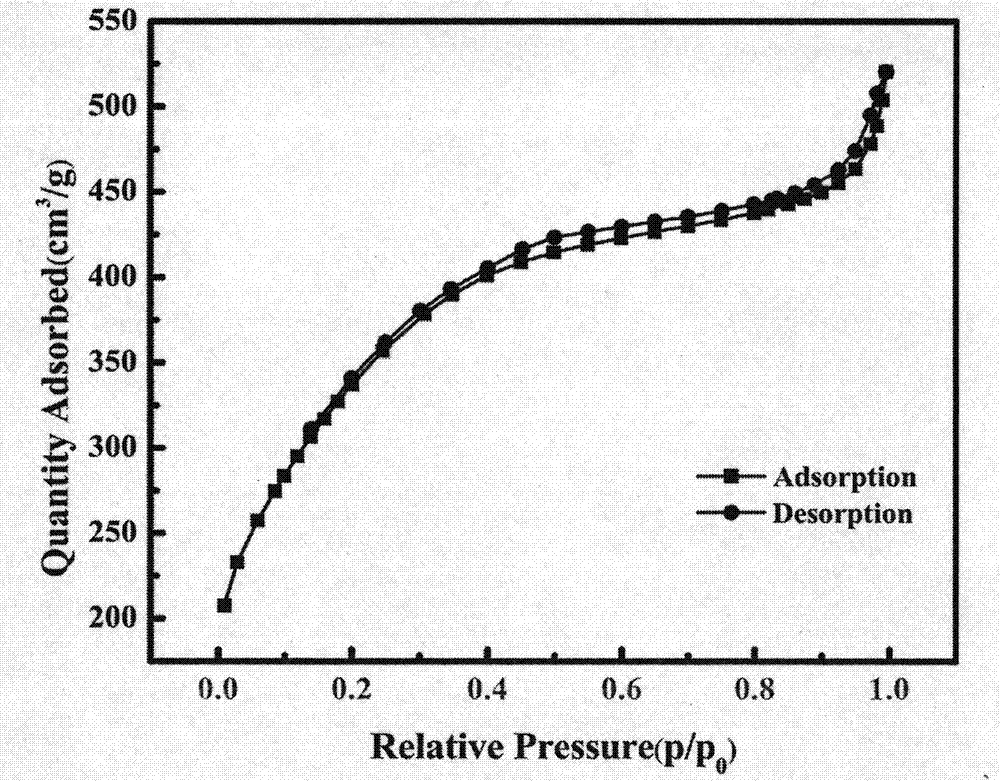

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com