Novel belt filter press

A belt filter press, a new type of technology, applied in dehydration/drying/concentrated sludge treatment, sludge treatment, water/sludge/sewage treatment, etc., can solve poor dehydration effect, low production efficiency, and sewage treatment capacity Small and other problems, to achieve the effect of unique technology, high strength, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

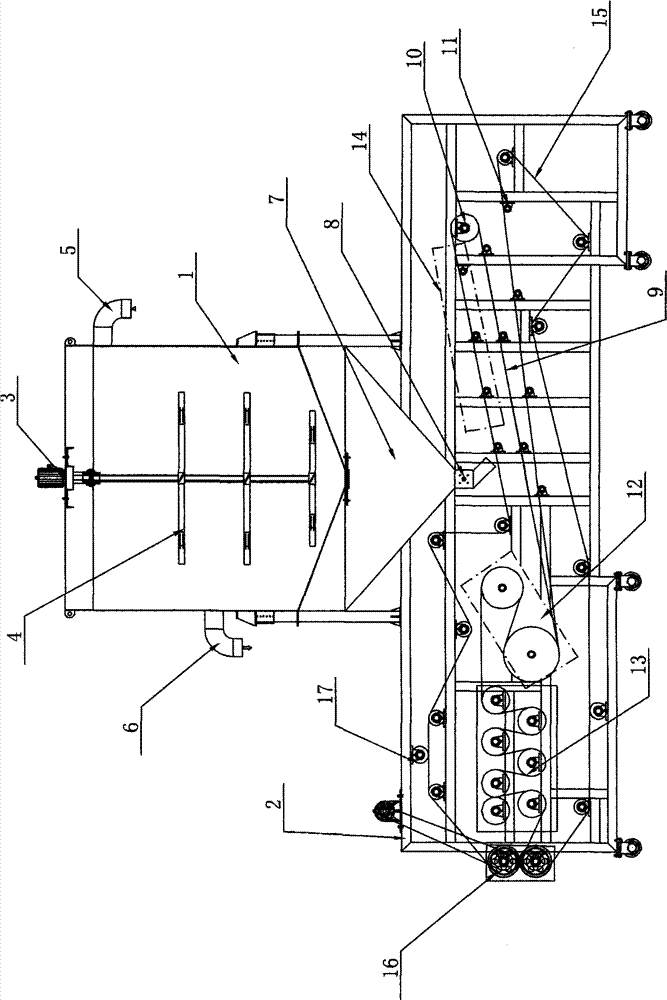

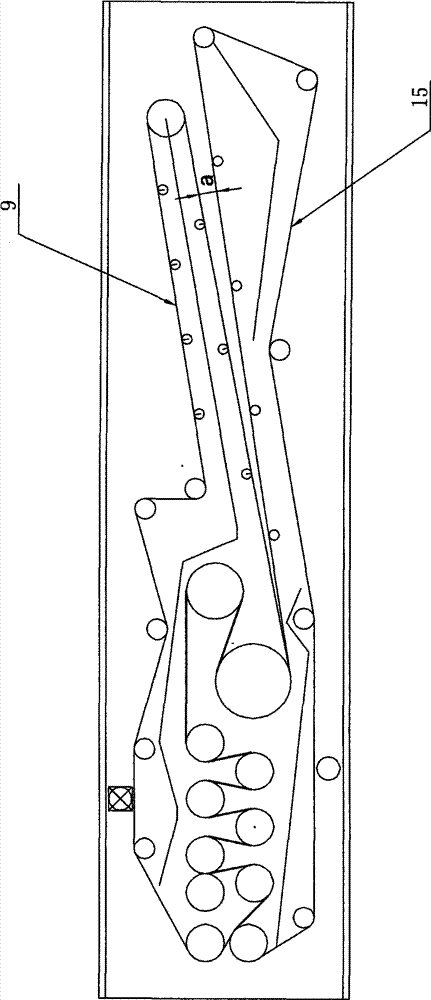

[0017] see Figure 1-2 , the specific embodiment adopts the following technical scheme: it includes a pretreatment device 1 and a dehydration device 2, the pretreatment device 1 is fixed on the middle upper end of the dehydration device 2 through the cooperation of bolts and support frames, and the top end of the pretreatment device 1 is fixed There is a stirring motor 3, which is connected to the stirring impeller 4 inside the pretreatment device 1. The sludge inlet 5 and the supernatant liquid discharge port 6 are respectively arranged on both sides of the pretreatment device 1. The bottom of the pretreatment device 1 is provided with Inverted cone-shaped discharge port 7, a flow regulating device 8 is arranged inside the inverted cone-shaped discharge port 7, and the inverted cone-shaped discharge port 7 extends to the upper end of the first dehydration transmission channel 9 inside the dehydration device 2, and the first dehydration transmission channel The right side of 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com