Method for preparing geopolymer by utilizing waste acid sludge

A technology of geopolymer and polluted acid residue, applied in cement production and other directions, can solve problems such as waste of resources and water pollution of Xiangjiang River, and achieve the effects of low cost, easy engineering implementation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

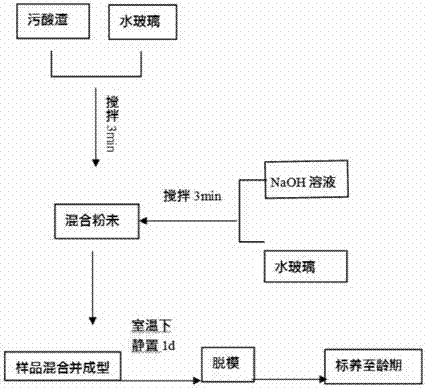

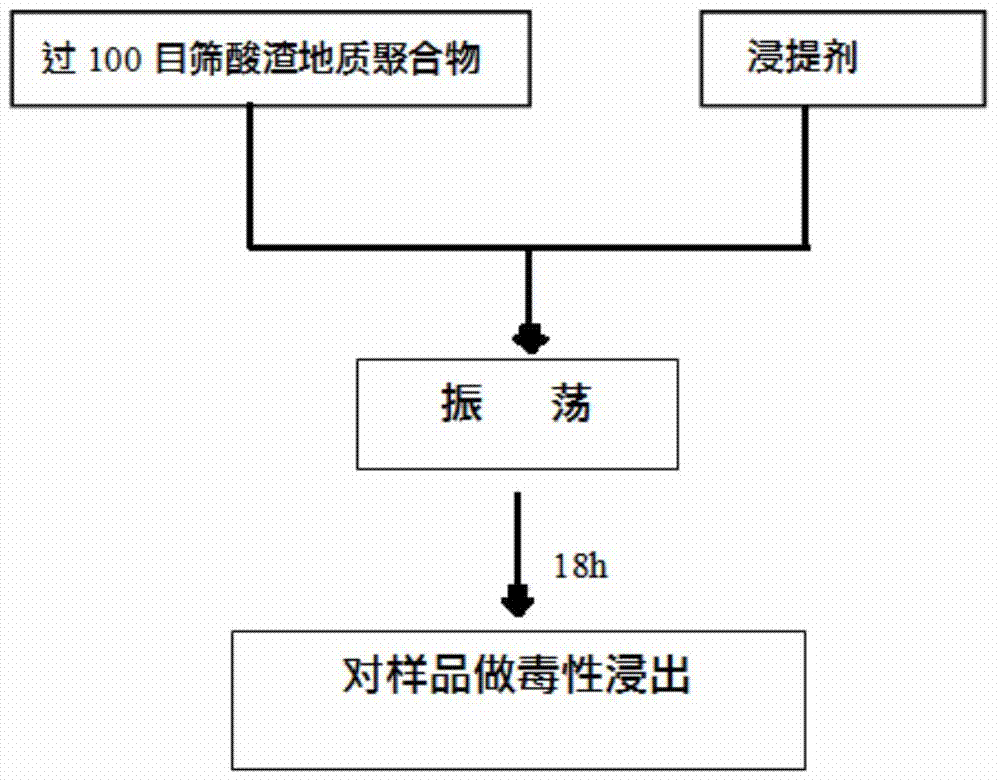

Method used

Image

Examples

Embodiment 1

[0027] First, the dirty acid slag and modified magnesium slag are mechanically ground to a particle size below 40 mesh, and then the dirty acid slag is mixed with the modified magnesium slag. The weight ratio of the dirty acid slag to the modified magnesium slag is 4:6, and the mixed slag Mix with bauxite according to the weight ratio of 7:3, add the alkali activator NaOH solution (mass concentration 40%) after mixing and water glass solution (mass concentration 20%), the quality of this NaOH solution and water glass solution all accounts for Prepare 8% of the total mass (referring to the sum of the weight of polluted acid slag, magnesium slag and bauxite), and prepare a mixture with a total amount of 5Kg.

[0028] Pour the mixed material into a 40mm×40mm×160mm triple mold, let it stand at room temperature for 1 day, demould it, and put it in a cement standard curing box for curing. The curing temperature is 80°C and the relative humidity is 85%. After 4 hours of curing, After...

Embodiment 2

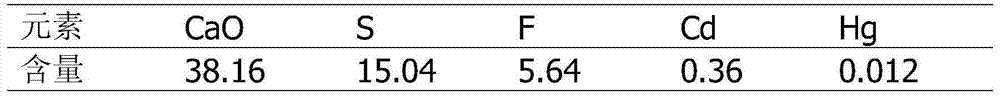

[0035] The polluted acid slag (chemical composition as shown in Table 1) and modified magnesium slag (chemical composition as shown in Table 2) are mechanically ground to a particle size below 40 mesh; then the polluted acid slag is mixed with the modified magnesium slag, The weight ratio of the modified magnesium slag is 3:7, the mixed slag and bauxite are mixed according to the weight ratio of 6:4, and the alkali activator NaOH (mass concentration 30%) and water glass (mass concentration 30%) are added, and NaOH The quality of water glass and water glass all account for 7% of the total mass of the preparation (referring to the sum of the weight of dirty acid slag, magnesium slag and bauxite), and the total amount of preparation is 5Kg of the mixture.

[0036] Pour the mixed material into a 40mm×40mm×160mm triple mold, let it stand at room temperature for 1 day, demould it, and put it in a cement standard curing box for curing. The curing temperature is 75°C, and the curing ti...

Embodiment 3

[0042] The polluted acid slag (chemical composition as shown in Table 1) and modified magnesium slag (chemical composition as shown in Table 2) are mechanically ground to a particle size below 40 mesh; then the polluted acid slag is mixed with the modified magnesium slag, The weight ratio of the modified magnesium slag is 2:8, the mixed slag (weight ratio) and bauxite are mixed according to the weight ratio of 8:2, and the alkali activator NaOH and water glass are added, NaOH (mass concentration 30%) and water glass (mass concentration 25%) accounted for 10% of the total mass of the preparation (referring to the sum of the weight of polluted acid slag, magnesium slag and bauxite), and the total amount of preparation was 5Kg of the mixture. Pour the mixed material into a 40mm×40mm×160mm triple mold, let it stand at room temperature for 1 day, demould, put it in a standard curing box for curing, the curing temperature is 70°C, after 5 hours of curing time, the relative humidity i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com