Anisotropic particle preparation method based on change of hydrophilicities of non-crosslinked seeds

An anisotropic and hydrophilic technology, applied in the field of synthesis of anisotropic asymmetric composite particles, can solve problems such as poor fluidity, and achieve the effect of simple and easy synthesis process, universality, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0030] Implementation Case 1 Preparation of Anisotropic PVC / PS Composite Particles

[0031] Preparation of seed emulsion:

[0032] Preparation of anisotropic particles:

[0033] Add 6.0g of hydrophilic monomer acetoacetoxyethyl methacrylate (AAEM), 600.0g of deionized water, and 0.72g of potassium persulfate to a 2L autoclave, seal the autoclave, and repeatedly vacuumize and fill it with nitrogen three times. Ensure that the atmosphere before the reaction is nitrogen, the pressure is normal pressure, start stirring, set the stirring speed to 300 rpm, add 60.0g of seed monomer vinyl chloride (VC) after stirring for 15 minutes, and quickly heat up to 55°C after stirring for 15 minutes Reaction temperature, when the pressure drops to 0.25MPa, the reaction is stopped, and the unreacted vinyl chloride monomer is removed under reduced pressure (vacuum degree is about 0.0995MPa), and the PVC seed emulsion is obtained. Immediately, the emulsion samples were taken directly, and t...

Embodiment example 2

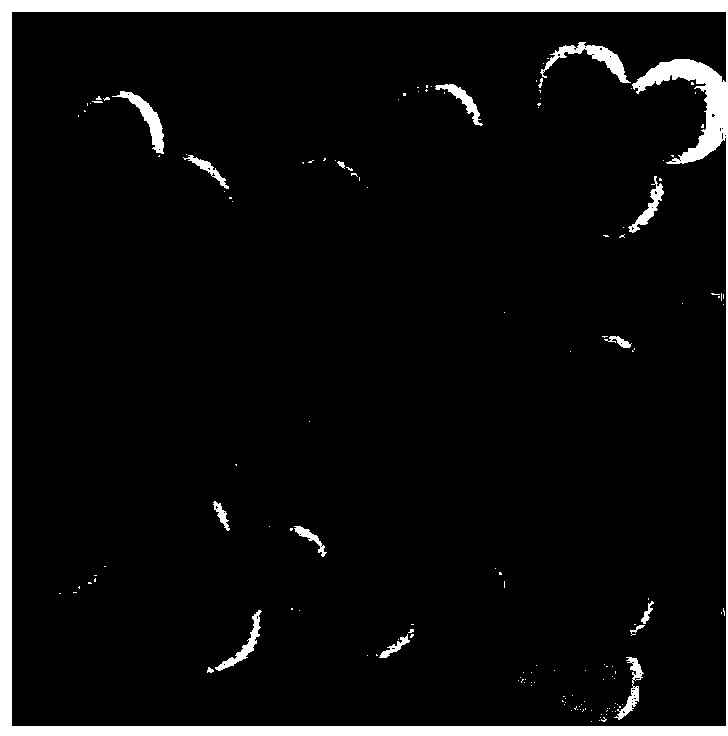

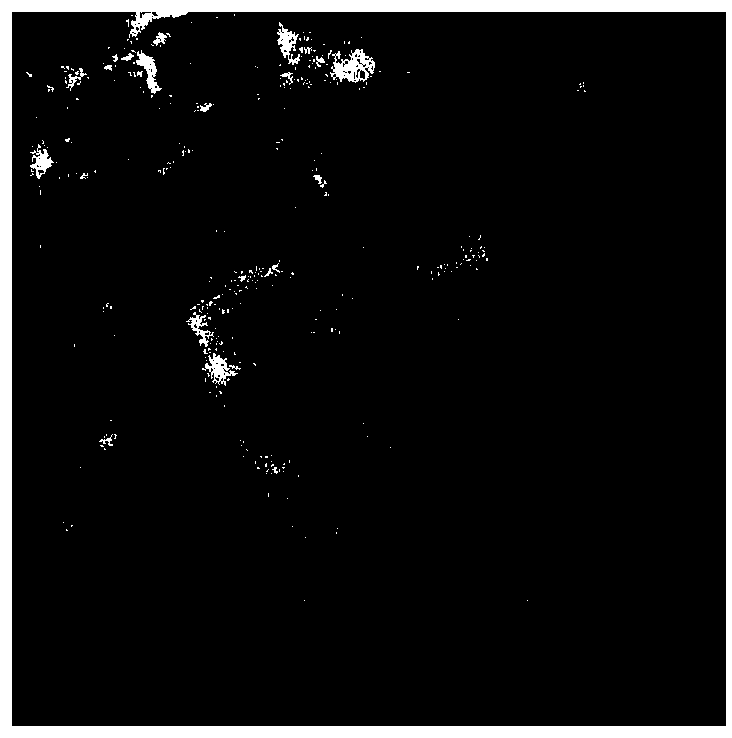

[0041] The polymerization reaction time of implementation case 2 is 5 hours, and all the other implementation processes are the same as implementation case 1, and the SEM photograph of the composite particle form prepared by implementation case 2 is shown in the appendix Figure 5 , it can be seen that the composite latex particles present a uniform CH 4 Morphology of molecular configuration. The average size of the composite latex is 730nm, which is 388nm larger than the average particle size of PVC seeds which is 315nm.

[0042] Figure 6 It is the TEM photo of composite latex particles after staining and sectioning, in which the PS phase is easily replaced by O S o 4 The steam is dyed dark, and the PVC as a seed cannot be dyed. The internal morphology of the more complex composite latex particles can be observed through the TEM photo, and there is a pure PS phase ( Figure 6 d), there are also composite phases containing one, two, three PS protrusions ( Figure 6 a,b,c)...

Embodiment example 3-4

[0045] The polymerization reaction time of implementation case 3-4 is respectively 2h, 8h, and all the other implementation processes are the same as implementation case 1, and the SEM photograph of the composite particle form prepared by implementation case 3-4 is shown in the attachment Figure 7-8 .

[0046] Depend on Figure 7-8 It can be observed from SEM photos that when the polymerization time is 2 hours, there are one or two small protrusions and three or four large protrusions in the composite particles, and when the polymerization time is 8 hours, the protrusions are almost merged together. From the implementation cases 1-4, the PS protrusions of the PVC / PS composite particles prepared from the reaction time of 30 minutes to 8 hours gradually increased and the number gradually decreased. This is to stabilize the latex particles, and the small PS protrusions in the initial stage of the polymerization reaction are continuously merged. , which reduces the system free e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com