Transformer sealing pad and preparation method thereof

A technology for gaskets and transformers, applied in the field of transformer parts, can solve problems such as unstable mechanical properties, economic losses of power systems and users, and easy aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

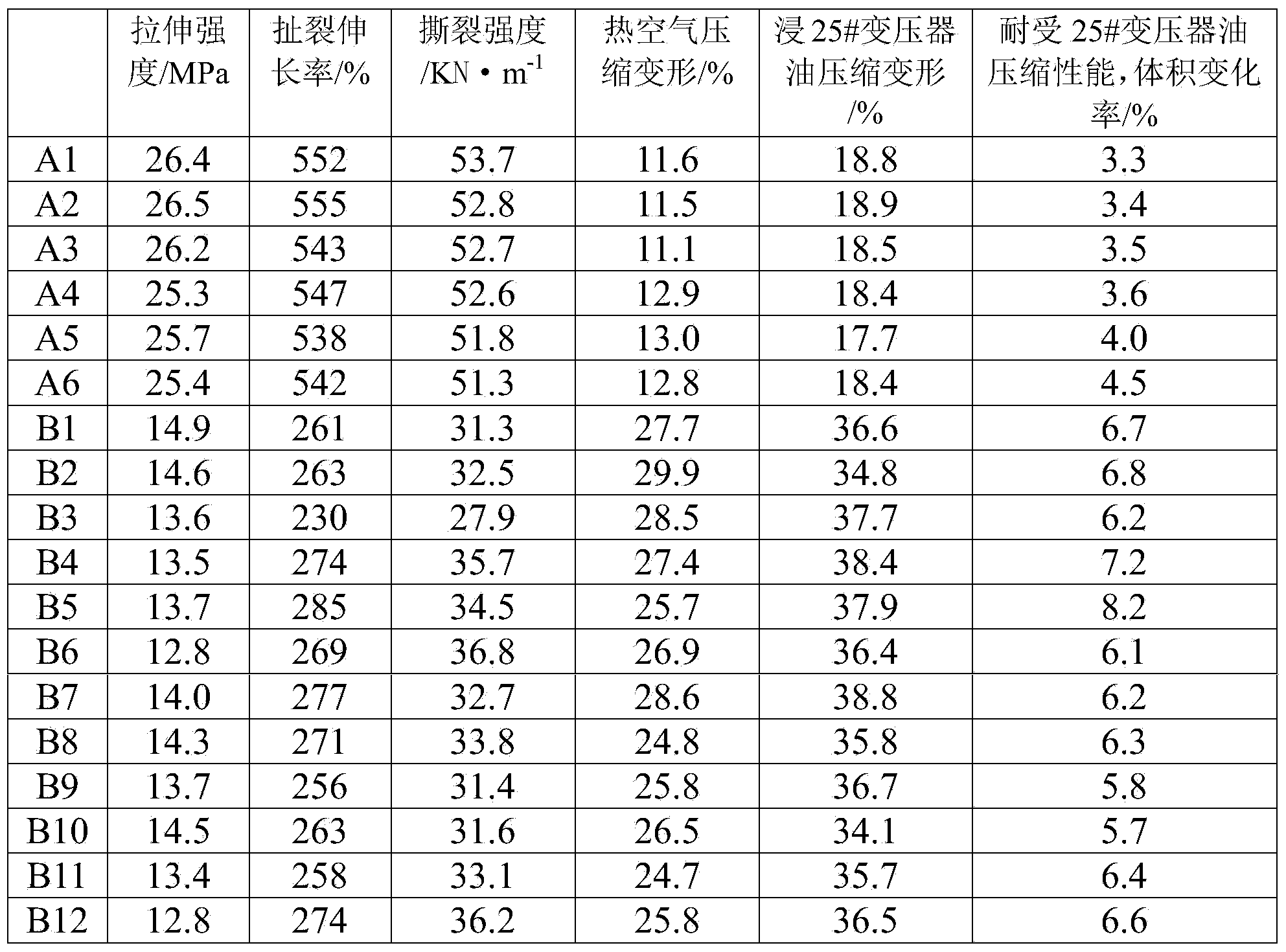

Examples

preparation example Construction

[0013] The present invention provides a kind of preparation method of transformer gasket, and described preparation method comprises:

[0014] a. At 125-135°C, knead epichlorohydrin rubber, carbon black, silicone rubber, dibutyl adipate and expanded vermiculite to obtain the first mixture;

[0015] b. Add zinc chloride, zinc stearate, nano-titanium dioxide, accelerator and anti-aging agent to the first mixture at 90-100°C and knead to obtain the second mixture;

[0016] c. kneading the second mixture and vulcanizing agent at 170-190° C. to perform vulcanization treatment to obtain a transformer gasket;

[0017] Wherein, relative to 100 parts by weight of chlorohydrin rubber, the consumption of the carbon black is 7-11 parts by weight, the consumption of the silicone rubber is 40-60 parts by weight, and the consumption of the dibutyl adipate is 20 parts by weight. -25 parts by weight, the consumption of the expanded vermiculite is 8-12 parts by weight, the consumption of the z...

Embodiment 1

[0031] a. At 130°C, mix 100kg of chlorohydrin rubber, 9kg of carbon black, 50kg of silicone rubber, 22kg of dibutyl adipate and 10kg of expanded vermiculite for 1.5h to obtain the first mixture; After heat treatment at 220°C for 2.5 hours and grinding, the particle size of expanded vermiculite is 1 mm; the weight average molecular weight of epichlorohydrin rubber is 70,000; the weight average molecular weight of silicone rubber is 40,000.

[0032] b. At 95°C, 3.5 kg of zinc chloride, 20 kg of zinc stearate, 1 kg of nano-titanium dioxide, 1.3 kg of N-tert-butyl bis-2-benzothiazole sulfenic acid amine and 2,2,4-tri 0.8 kg of methyl-1,2-dihydroquinoline was added to the first mixture and kneaded for 10 hours to prepare the second mixture; wherein, the particle size of nano-titanium dioxide was 8 nm.

[0033] c. Knead the second mixture and 4 kg of tetraethylthiuram disulfide at 180° C. for 6 hours to perform vulcanization treatment to obtain transformer gasket A1.

[0034] The t...

Embodiment 2

[0036] a. At 125°C, mix 100kg of chlorohydrin rubber, 7kg of carbon black, 40kg of silicone rubber, 20kg of dibutyl adipate and 8kg of expanded vermiculite for 1 hour to obtain the first mixture; After heat treatment at ℃ for 2 hours and grinding, the particle size of expanded vermiculite is 0.5 mm; the weight average molecular weight of epichlorohydrin rubber is 50,000; the weight average molecular weight of silicone rubber is 20,000.

[0037] b. At 90°C, 3 kg of zinc chloride, 15 kg of zinc stearate, 0.5 kg of nano-titanium dioxide, 1.2 kg of N-tert-butyl bis-2-benzothiazole sulfenic acid amine and 2,2,4-tri 0.5 kg of methyl-1,2-dihydroquinoline was added to the first mixture and kneaded for 8 hours to prepare the second mixture; wherein, the particle size of nano-titanium dioxide was 5 nm.

[0038] c. Knead the second mixture and 3 kg of tetraethylthiuram disulfide at 170° C. for 5 hours to perform vulcanization treatment to obtain transformer gasket A2.

[0039] The tensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com