SiC/Cu composite material and preparation method thereof

A technology of composite materials and mixed powders, which is applied in the preparation of SiC/Cu composite materials and in the field of SiC/Cu composite materials, can solve the problems of poor comprehensive performance and inability to meet the needs of use, so as to improve hardness and flexural strength, improve Wrapping effect, the effect of stabilizing comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

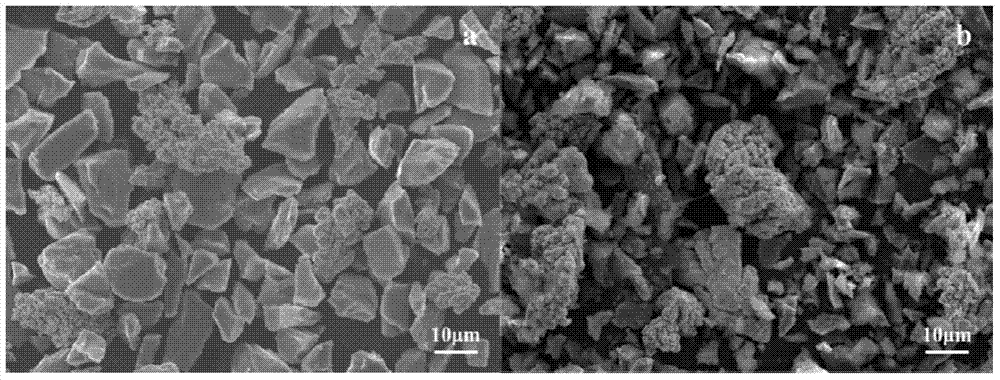

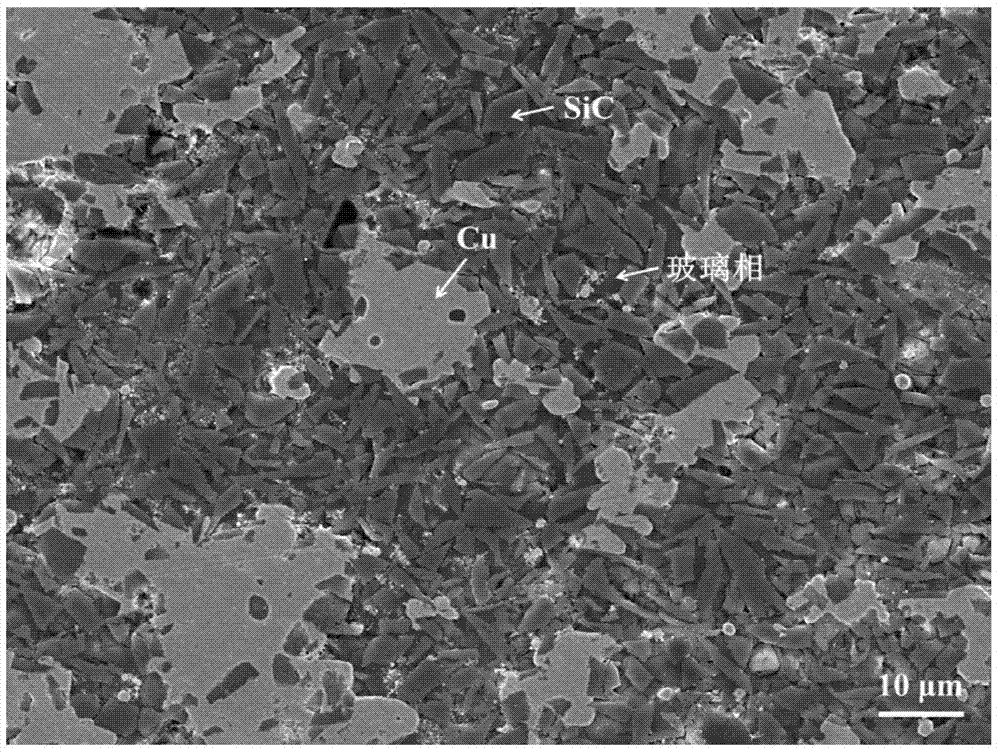

[0032] In the SiC / Cu composite material of this embodiment, the continuous phase is a glass phase, and SiC particles and Cu particles are uniformly wrapped in the glass phase. In the composite material, the volume ratio of SiC, Cu and the glass phase is 1:1:0.6; the composition of the glass phase is SiO 2 , B 2 o 3 and Na 2 O, SiO 2 , B 2 o 3 with Na 2 The mass ratio of O is 0.5:0.2:0.3; the density of the glass phase is 2.4g / cm 3 . The size of the SiC particles is 5-15 μm; the size of the Cu particles is 10-30 μm.

[0033] The preparation method of the SiC / Cu composite material of the present embodiment comprises the following steps:

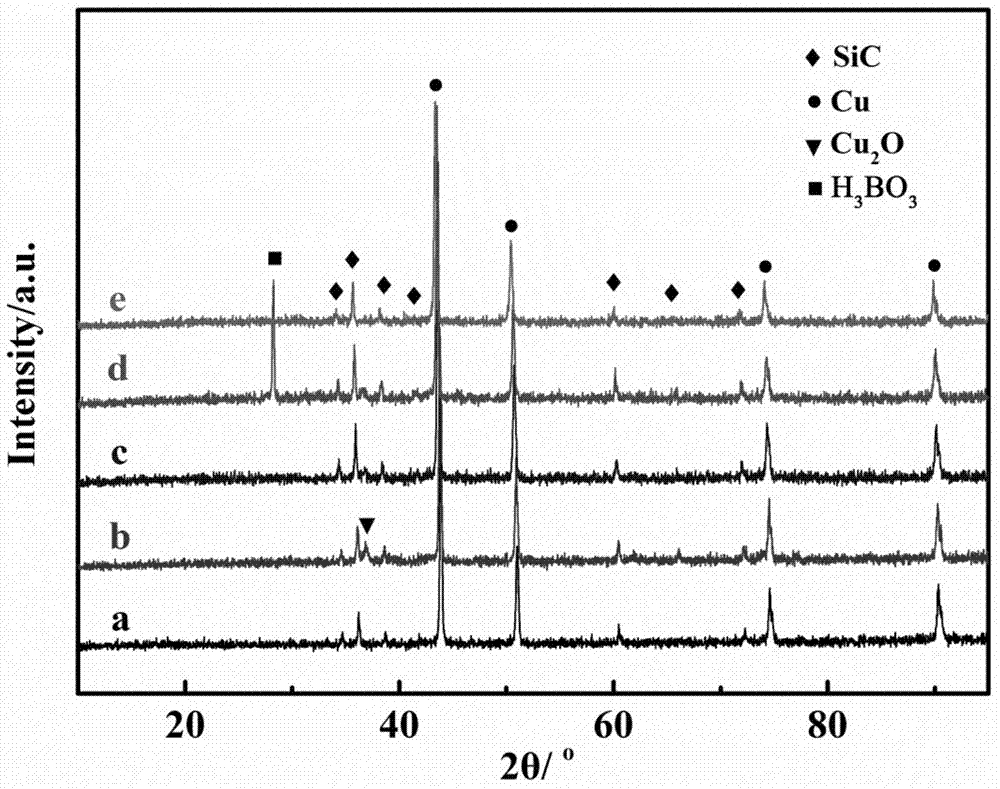

[0034] 1) Grind and mix SiC powder and Cu powder evenly at a volume ratio of 1:1. After passing through a 200-mesh screen for 3 times, heat it to 200°C in a muffle furnace and keep it for 20 minutes to oxidize the surface of Cu particles to form a layer of Cu. 2 O, get mixed powder A;

[0035] 2) Use the sol-gel method to make the su...

Embodiment 2

[0044] In the SiC / Cu composite material of this embodiment, the continuous phase is a glass phase, and SiC particles and Cu particles are uniformly wrapped in the glass phase. In the composite material, the volume ratio of SiC, Cu and the glass phase is 1:1.5:0.4; the composition of the glass phase is SiO 2 , B 2 o 3 and Na 2 O, SiO 2 , B 2 o 3 with Na 2 The mass ratio of O is 0.5:0.3:0.2; the density of the glass phase is 2.3g / cm 3 . The size of the SiC particles is 5-15 μm; the size of the Cu particles is 10-30 μm.

[0045] The preparation method of the SiC / Cu composite material of the present embodiment comprises the following steps:

[0046] 1) Grind and mix SiC powder and Cu powder evenly at a volume ratio of 1:1.5. After passing through a 200-mesh screen for 3 times, heat it to 150°C in a muffle furnace and keep it warm for 30 minutes to oxidize the surface of Cu particles to form a layer of Cu. 2 O, get mixed powder A;

[0047] 2) Use the sol-gel method to ma...

Embodiment 3

[0052] In the SiC / Cu composite material of this embodiment, the continuous phase is a glass phase, and SiC particles and Cu particles are uniformly wrapped in the glass phase. In the composite material, the volume ratio of SiC, Cu and the glass phase is 1:0.5:0.1; the composition of the glass phase is SiO 2 , B 2 o 3 and Na 2 O, SiO 2 , B 2 o 3 with Na 2 The mass ratio of O is 0.5:0.1:0.4; the density of the glass phase is 2.5g / cm 3 . The size of the SiC particles is 5-15 μm; the size of the Cu particles is 10-30 μm.

[0053] The preparation method of the SiC / Cu composite material of the present embodiment comprises the following steps:

[0054] 1) Grind and mix SiC powder and Cu powder evenly at a volume ratio of 1:0.5. After passing through a 200-mesh screen for 3 times, heat it to 250°C in a muffle furnace and keep it warm for 30 minutes to oxidize the surface of Cu particles to form a layer of Cu. 2 O, get mixed powder A;

[0055] 2) Use the sol-gel method to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com