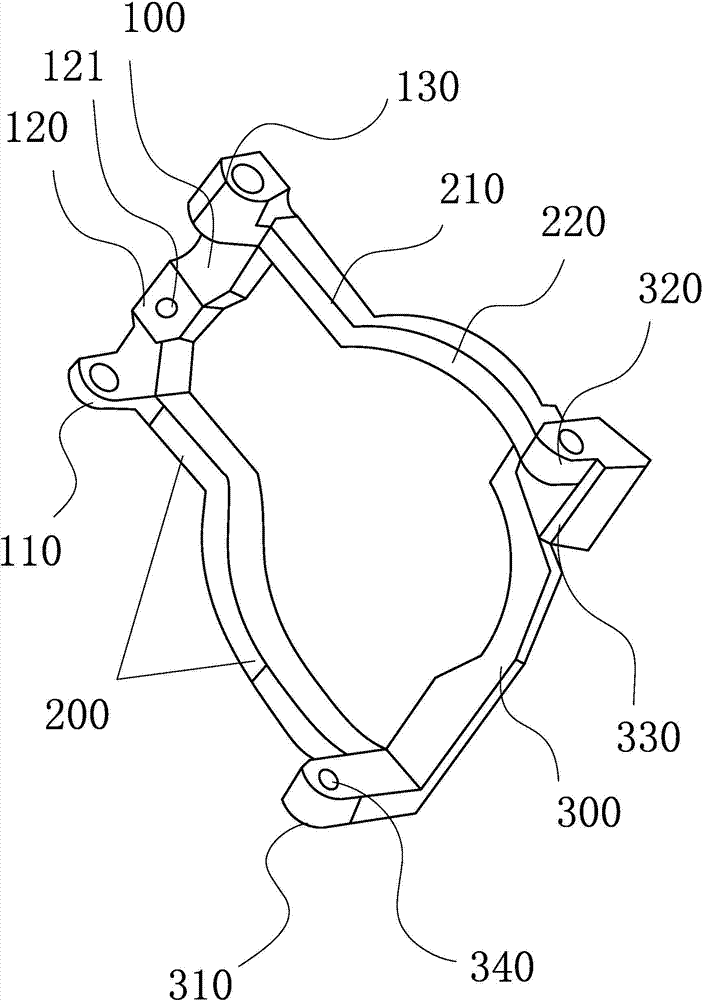

Feed dog rack used for electronic sewing machine and machining method of feed dog rack

A processing method and sewing machine technology, which are applied to sewing machine components, sewing equipment, cloth feeding mechanisms, etc., can solve the problems that the left and right height cannot be adjusted, affect the sewing performance of the sewing machine, and the unilateral inclination of the tooth frame, etc., and achieve simple structure and convenient processing. Manufacture, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

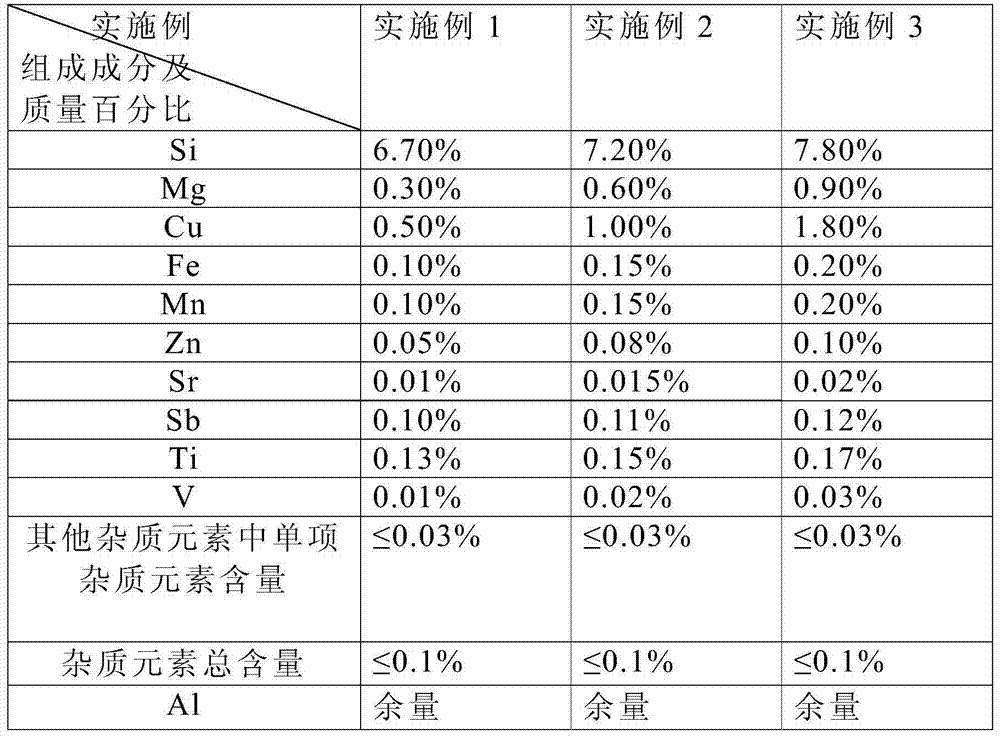

[0037] Ingredients: According to the composition and mass percentage ingredients of the aluminum-silicon-magnesium cast aluminum alloy used in the tooth frame described in Table 1, Example 1;

[0038] Melting: first add half of the aluminum ingot, after the aluminum ingot is completely melted at 730°C, add magnesium, zinc, copper and the remaining aluminum ingot until the magnesium, zinc, and copper are completely melted, when the temperature of the molten aluminum is 700°C, Then add the master alloy and stir evenly; the magnesium is pure magnesium, the zinc is pure zinc, and the copper is electrolytic copper. Alloys, aluminum-iron alloys with 7-10% iron content, aluminum-strontium alloys with 5-8% strontium content, aluminum-vanadium alloys with 6-10% vanadium content, aluminum-titanium alloys with 7-10% titanium content, antimony Aluminum antimony alloy with a content of 5-8%;

[0039] Die-casting: The smelted aluminum liquid is successively refined by deslagging and degass...

Embodiment 2

[0042] Ingredients: according to the composition and mass percentage ingredients of the aluminum-silicon-magnesium cast aluminum alloy used in the tooth frame described in Table 1, Example 2;

[0043] Melting: first add half of the aluminum ingot, after the aluminum ingot is completely melted at 750°C, add magnesium, zinc, copper and the remaining aluminum ingot until the magnesium, zinc, and copper are completely melted, when the temperature of the molten aluminum is 720°C, Then add the master alloy and stir evenly; the magnesium is pure magnesium, the zinc is pure zinc, and the copper is electrolytic copper. Alloys, aluminum-iron alloys with 7-10% iron content, aluminum-strontium alloys with 5-8% strontium content, aluminum-vanadium alloys with 6-10% vanadium content, aluminum-titanium alloys with 7-10% titanium content, antimony Aluminum antimony alloy with a content of 5-8%;

[0044] Die-casting: The smelted aluminum liquid is successively refined by deslagging and degass...

Embodiment 3

[0047] Ingredients: according to the composition and mass percentage ingredients of the aluminum-silicon-magnesium cast aluminum alloy used in the tooth frame described in Table 1, Example 3;

[0048] Melting: first add half of the aluminum ingot, after the aluminum ingot is completely melted at 780°C, add magnesium, zinc, copper and the remaining aluminum ingot until the magnesium, zinc, and copper are completely melted, when the temperature of the molten aluminum is 750°C, Then add the master alloy and stir evenly; the magnesium is pure magnesium, the zinc is pure zinc, and the copper is electrolytic copper. Alloys, aluminum-iron alloys with 7-10% iron content, aluminum-strontium alloys with 5-8% strontium content, aluminum-vanadium alloys with 6-10% vanadium content, aluminum-titanium alloys with 7-10% titanium content, antimony Aluminum antimony alloy with a content of 5-8%;

[0049] Die-casting: The smelted aluminum liquid is successively refined by deslagging and degass...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap