Liquid phase analysis method of maleic acid asenapine and impurities thereof

A technology for asenapine maleate and impurities, which is applied in the field of analytical chemistry, can solve problems such as incomplete removal of intermediates, affecting the purity and quality of drugs, and achieve the effect of ensuring quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

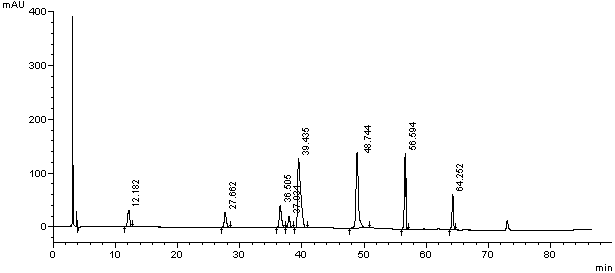

Embodiment 1

[0036] Instruments and Conditions:

[0037] High performance liquid chromatography: Shimadzu: LC-20AT, CBM-20A, SIL-20AC, SPD-M20A, CTO-10ASvp;

[0038] Column: C 8 (Apollo, 250×4.6mm, 5μm)

[0039] Mobile phase: Phase A: 0.02mol / L potassium dihydrogen phosphate buffer solution (weigh 2.72g of potassium dihydrogen phosphate, add water to dissolve and set the volume to 1000mL, adjust the pH value to 3.5 with dilute phosphoric acid), phase B: acetonitrile, using a gradient Elution;

[0040] T(min) 0 35 65 75 80 90 B% 23 30 60 60 23 23

[0041] Flow rate: 1.0mL / min

[0042] Detection wavelength: 220nm

[0043] Column temperature: 25°C

[0044] Injection volume: 10 μL.

[0045] Experimental steps:

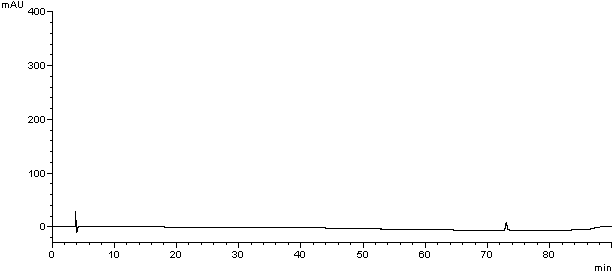

[0046] Take an appropriate amount of asenapine maleate and its impurities, dissolve the samples with acetonitrile respectively, and prepare a sample solution containing about 0.5 mg / mL of asenapine maleate and its impurities; another appropriate am...

Embodiment 2

[0048] Instruments and Conditions:

[0049] High performance liquid chromatography: Shimadzu: LC-20AT, CBM-20A, SIL-20AC, SPD-M20A, CTO-10ASvp;

[0050] Column: C 8 (Apollo, 250×4.6mm, 5μm)

[0051]Mobile phase: Phase A: 0.02mol / L potassium dihydrogen phosphate buffer solution (weigh 2.72g of potassium dihydrogen phosphate, add water to dissolve and set the volume to 1000mL, adjust the pH value to 3.5 with dilute phosphoric acid), phase B: methanol, using a gradient Elution;

[0052] T(min) 0 30 40 60 61 70 B% 40 52 70 75 40 40

[0053] Flow rate: 1.0mL / min

[0054] Detection wavelength: 220nm

[0055] Column temperature: 25°C

[0056] Injection volume: 10 μL.

[0057] Experimental steps:

[0058] Take an appropriate amount of asenapine maleate and its impurities, dissolve the samples in methanol respectively, and prepare a sample solution containing about 0.5 mg / mL of asenapine maleate and its impurities; another appropriate amount of met...

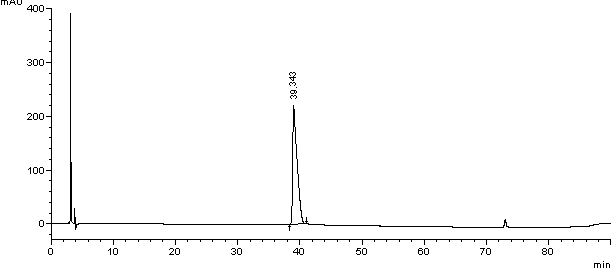

Embodiment 3

[0060] Instruments and Conditions:

[0061] High performance liquid chromatography: Shimadzu: LC-20AT, CBM-20A, SIL-20AC, SPD-M20A, CTO-10ASvp;

[0062] Column: C 8 (Apollo, 250×4.6mm, 5μm)

[0063] Mobile phase: Phase A: 0.02mol / L potassium dihydrogen phosphate buffer solution (weigh 2.72g of potassium dihydrogen phosphate, add water to dissolve and set the volume to 1000mL, adjust the pH value to 3.5 with dilute phosphoric acid), phase B: methanol, using a gradient Elution;

[0064] T(min) 0 30 40 70 71 80 B% 40 50 50 75 40 40

[0065] Flow rate: 1.0mL / min

[0066] Detection wavelength: 220nm

[0067] Column temperature: 25°C

[0068] Injection volume: 10 μL.

[0069] Experimental steps:

[0070] Take an appropriate amount of asenapine maleate and its impurities, dissolve the samples in methanol respectively, and prepare a sample solution containing about 0.5 mg / mL of asenapine maleate. Perform HPLC analysis according to the above condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com