MEMS cantilever type accelerometer and manufacture process thereof

An accelerometer and cantilever beam technology, applied in the field of sensors, can solve the problems of reducing the reliability of accelerometer detection, unsymmetrical vibration mode shape, collision between mass block and frame, etc., to ensure detection stability and reduce crosstalk and impact, the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with accompanying drawing, the present invention is described in further detail:

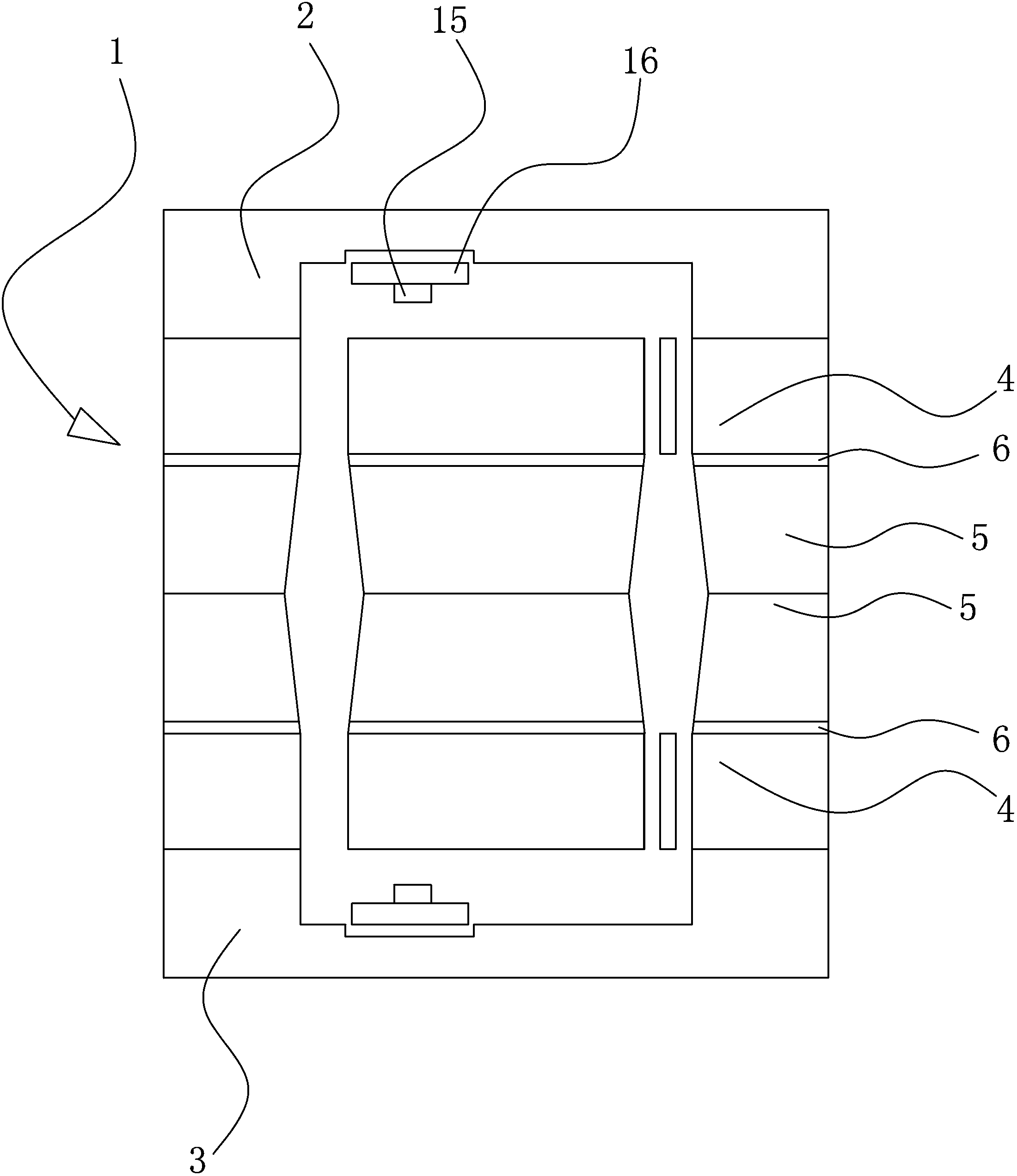

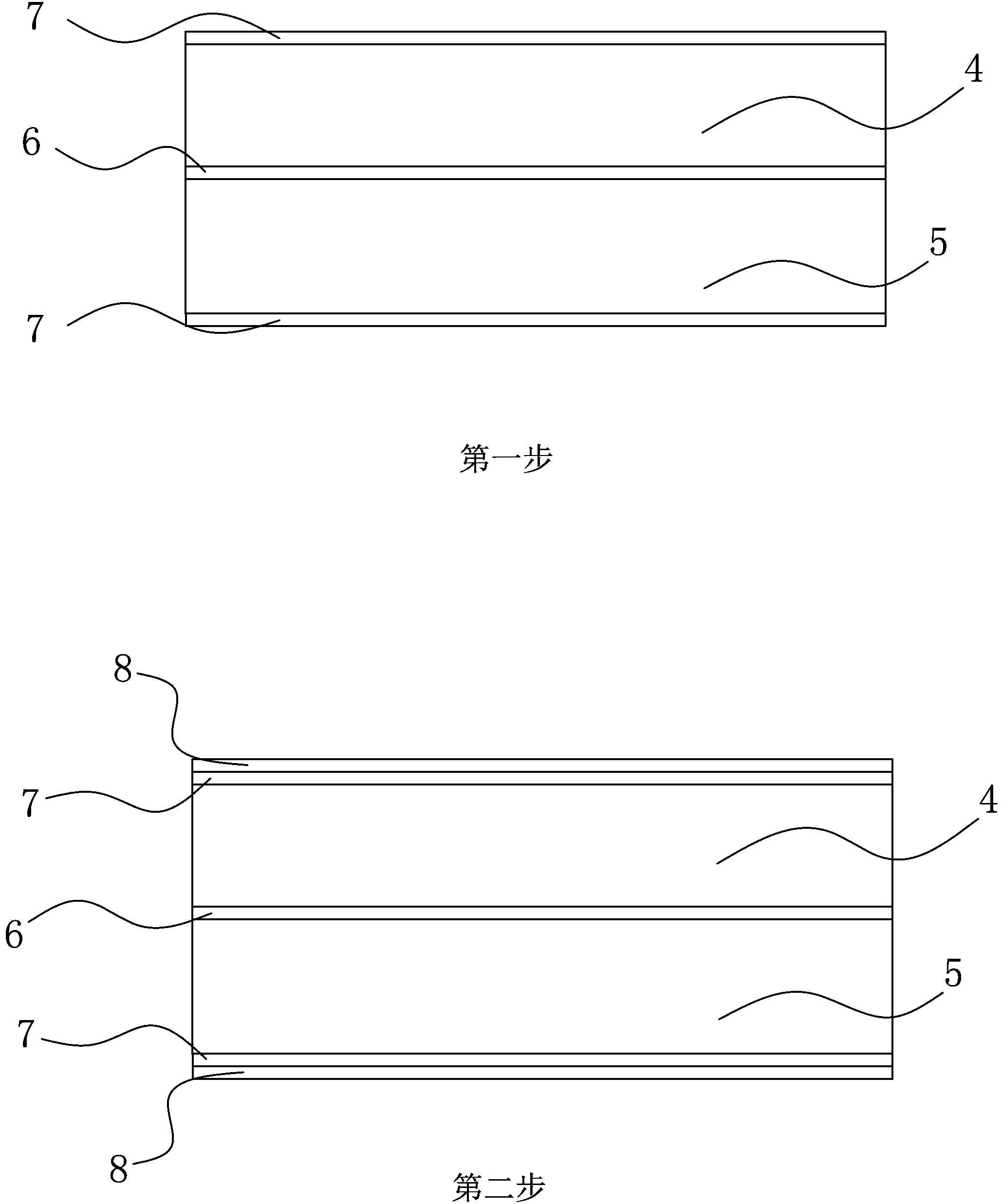

[0056] refer to figure 1 According to a MEMS cantilever accelerometer provided by the present invention, it comprises: a measuring body 1, an upper cover plate 2 connected to the measuring body 1 and a lower cover plate 3; the measuring body 1 adopts an upper silicon The epitaxial silicon-on-insulator structure of the layer 4 and the lower silicon layer 5 is referred to as the SOI structure. A buried oxide layer 6 is respectively arranged between each silicon layer.

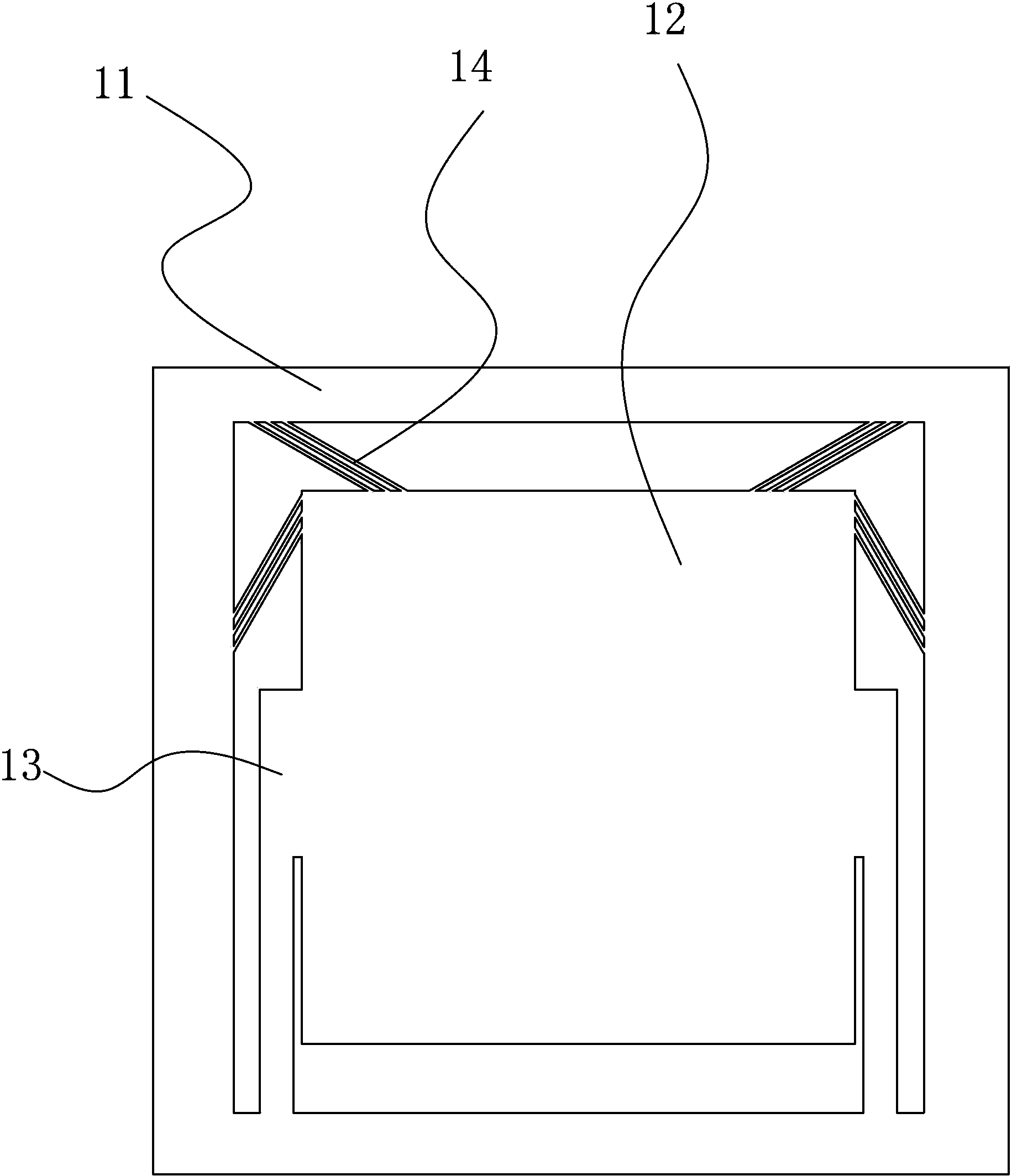

[0057] see figure 2 , the measuring body 1 includes a frame 11 and a mass block 12 located in the frame 11 ; the mass block 12 and the frame 11 are connected by a cantilever beam 13 . A plurality of cantilever beams 13 are arranged in the space between the proof mass 12 and the frame 11 . Preferably, the mass block 12 is a square, and the cantilever beams are symmetrically arranged on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com