Method for preparing high-performance metal nanowire transparent conducting thin film

A technology of transparent conductive film and metal nanowire, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., which can solve the problems of high price and brittleness of transparent conductive film, and achieve low cost and high transmittance efficiency, high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments.

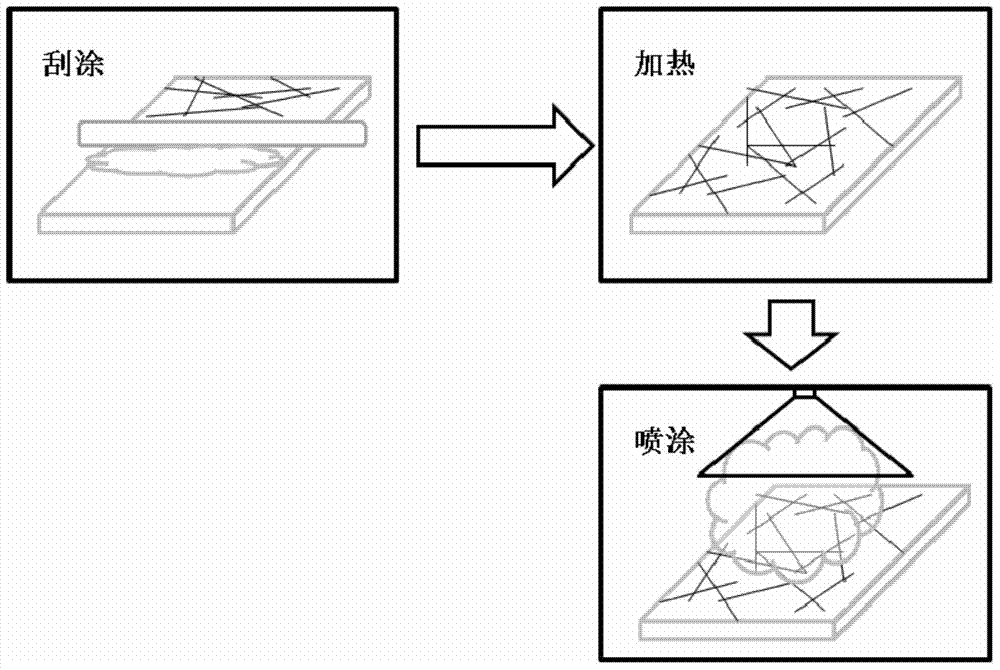

[0026] 1. Surface hydrophilic treatment: put the clean glass into an ozone plasma etching machine, and treat the surface at 90°C for 30 minutes;

[0027] 2. Scratch coating: use 3M adhesive tape to fix the glass with the hydrophilic side up on the toughened film board. Using the method of scraping, drop the prepared 0.35mg / ml silver nanowire colloid (3.5mg silver nanowires dispersed in 10ml of absolute ethanol) on the film, and then use a glass rod to scrape back and forth on the surface of the film for several times. After the second time, dry the surface of the substrate with a hair dryer;

[0028] 3. Repeat step 2 seven times to scrape and coat 8 layers of silver nanowire films in total.

[0029] 4. Heat treatment to improve the conductivity of the film: in step 3, the sample is heat-treated on a heating plate at 200°C for 10 minutes;

[0030] 5. Taking polyvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com