Technological method for electro-deposition of MnO2 on graphite substrate with cyclic voltammetry

A technology of cyclic voltammetry and process method is applied in the field of supercapacitor preparation, which can solve the problems of difficult to control sintering temperature, high cost of thermal decomposition, harm to the environment, etc., and achieves the effects of low solution cost, low price and fast deposition speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

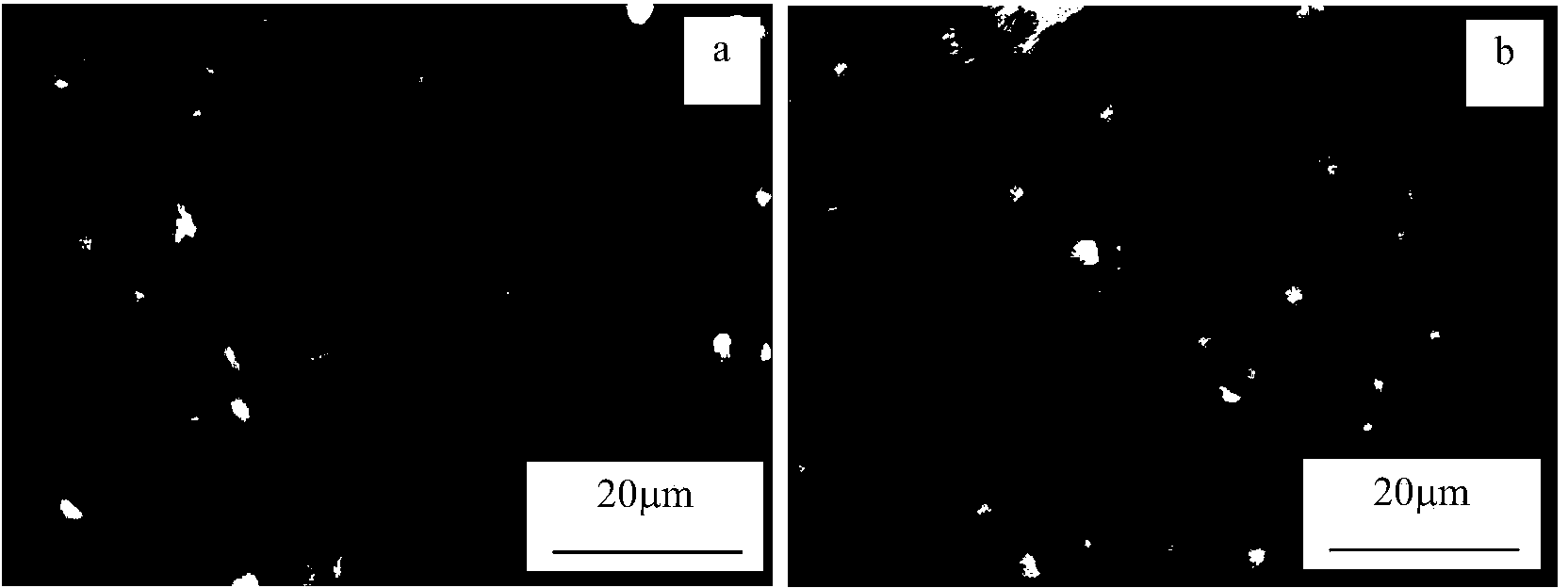

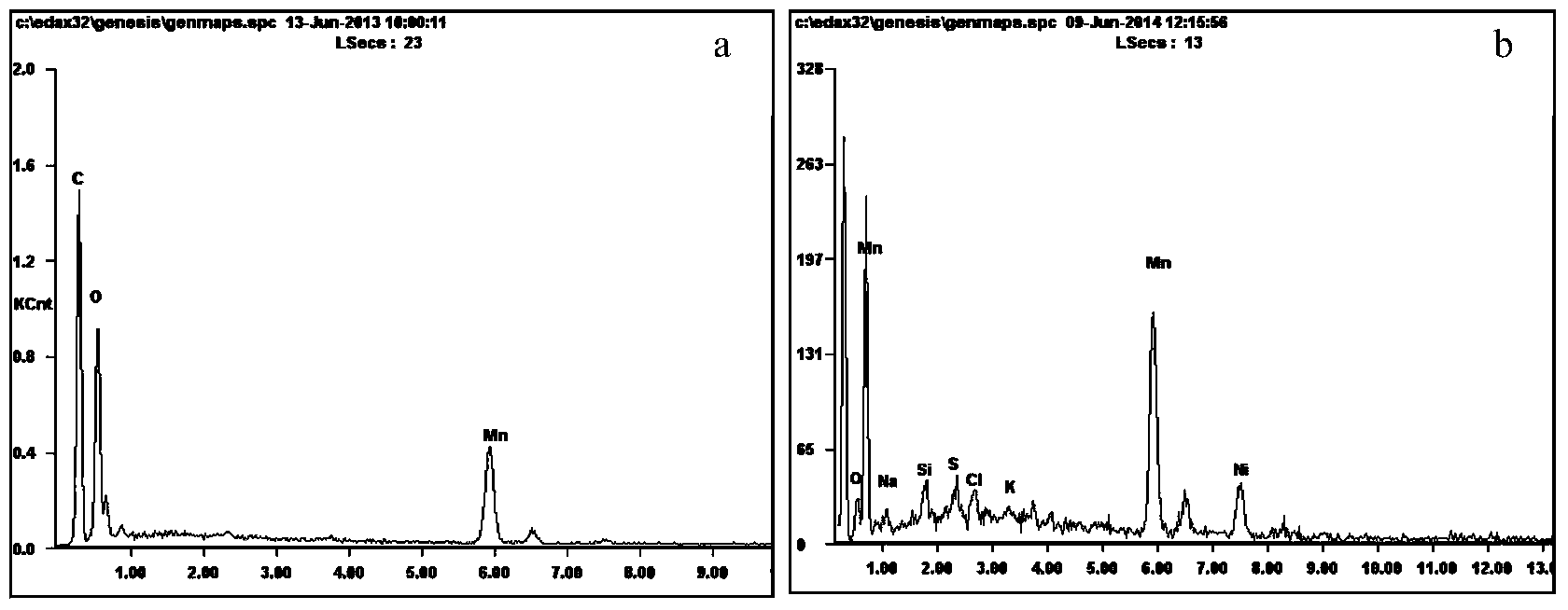

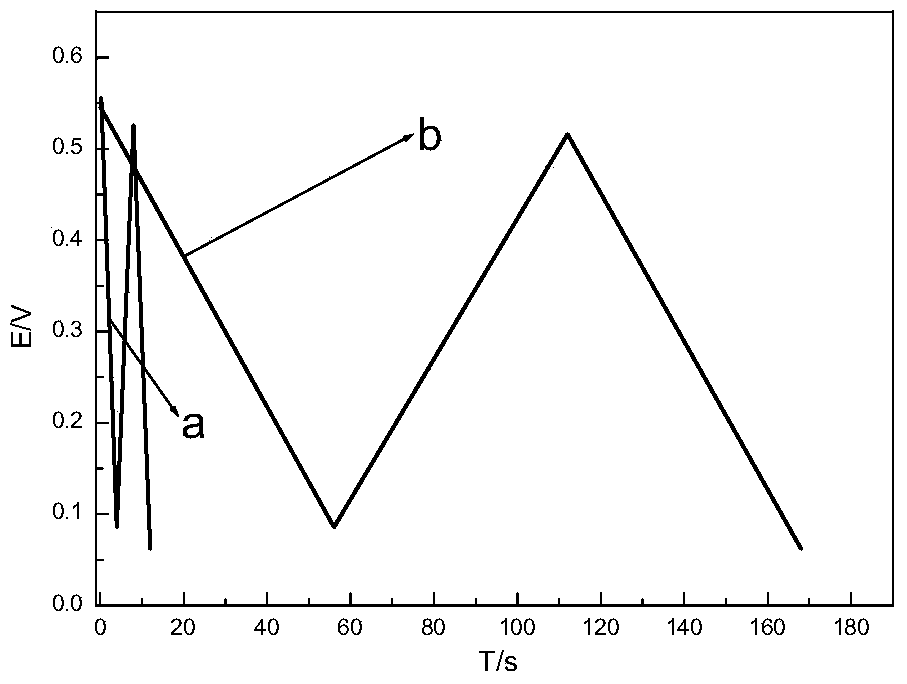

Image

Examples

Embodiment 1

[0050] Electrodeposition of MnO on Graphite Substrates by Cyclic Voltammetry 2 Process method, the steps are as follows:

[0051] Step 1. Acetone degreasing: remove the oil from the graphite matrix without changing the size of the graphite, use acetone to clean the graphite surface, and then use distilled water to clean;

[0052] Step 2. Activation: The composition of the activation solution is: the graphite activation solution is nitric acid with a mass percentage of 32%, the graphite is completely immersed in the activation solution, and the activation time is 4h;

[0053] Step 3. Activation: Submerge the activated substrate in the activation solution using a three-electrode system. The composition of the activation solution is: sulfuric acid 0.15mol / L; the temperature is 20°C, the scan rate is 0.10V / s, and the scan potential is -1.1~2.2 V, the number of cycles is 60 times;

[0054] Step 4. Deposition: After activation, place in the electrodeposition solution, the composit...

Embodiment 2

[0060] Electrodeposition of MnO on Graphite Substrates by Cyclic Voltammetry 2 Process method, the steps are as follows:

[0061] Step 1. Acetone degreasing: remove the oil from the graphite matrix without changing the size of the graphite, use acetone to clean the graphite surface, and then use distilled water to clean;

[0062] Step 2. Activation: The composition of the activation solution is: the graphite activation solution is nitric acid with a mass percentage of 32%, the graphite is completely immersed in the activation solution, and the activation time is 4h;

[0063] Step 3. Activation: Submerge the activated substrate in the activation solution using a three-electrode system. The composition of the activation solution is: sulfuric acid 0.15mol / L; the temperature is 30°C, the scan rate is 0.10V / s, and the scan potential is -1.1~2.2 V, the number of cycles is 60 times;

[0064] Step 4. Deposition: After activation, place in the electrodeposition solution, the composit...

Embodiment 3

[0070] Electrodeposition of MnO on Graphite Substrates by Cyclic Voltammetry 2 Process method, the steps are as follows:

[0071] Step 1. Acetone degreasing: remove the oil from the graphite matrix without changing the size of the graphite, use acetone to clean the graphite surface, and then use distilled water to clean;

[0072] Step 2. Activation: The composition of the activation solution is: the graphite activation solution is nitric acid with a mass percentage of 32%, the graphite is completely immersed in the activation solution, and the activation time is 4h;

[0073] Step 3. Activation: Submerge the activated substrate in the activation solution using a three-electrode system. The composition of the activation solution is: sulfuric acid 0.15mol / L; the temperature is 25°C, the scan rate is 0.10V / s, and the scan potential is -1.1~2.2 V, the number of cycles is 60 times;

[0074] Step 4. Deposition: After activation, place in the electrodeposition solution, the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com