Fiber end face grinder

A technology for optical fiber end faces and grinders, which is applied in the direction of grinding devices, grinding machine tools, grinding tools, etc., can solve the problems of few types of optical fiber connectors, complex transmission systems, and unfavorable portability, etc., achieve a wide range of grinding, ensure grinding quality, Simple and reliable transmission scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

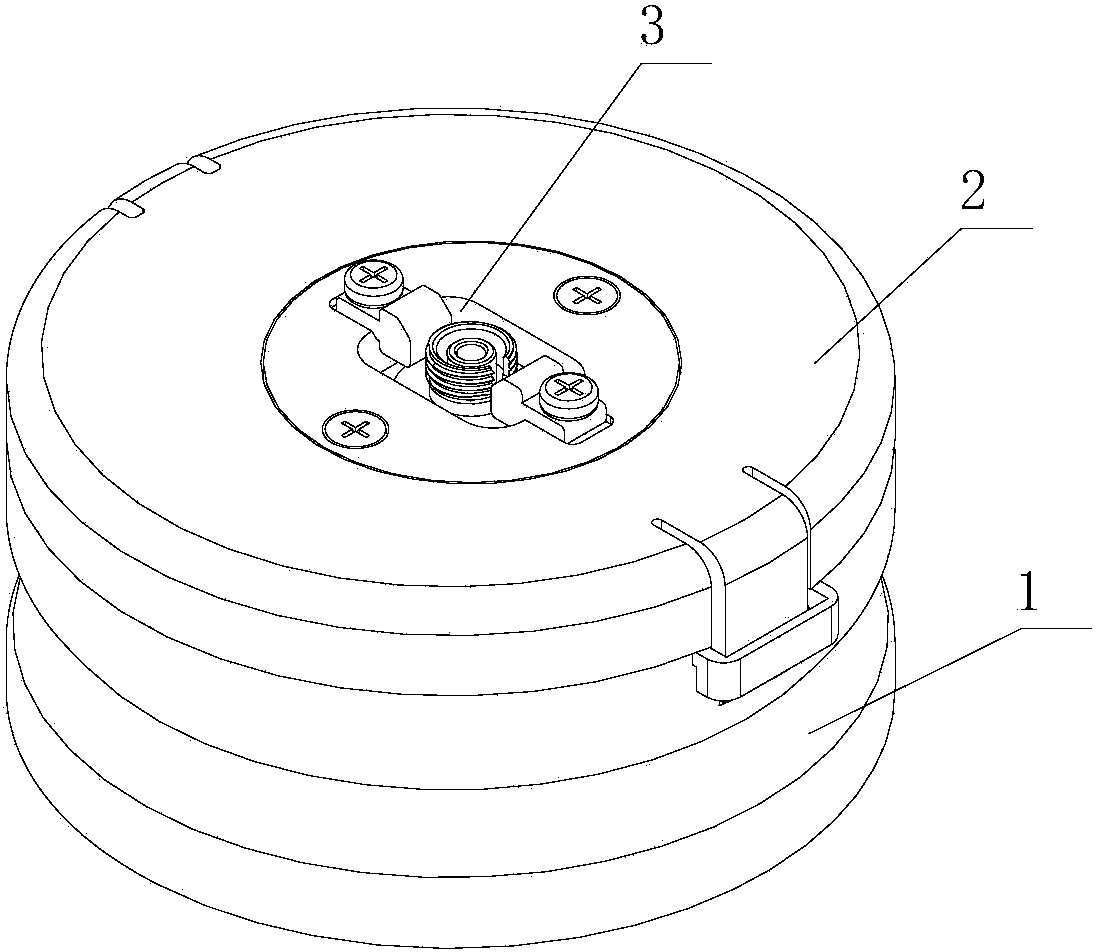

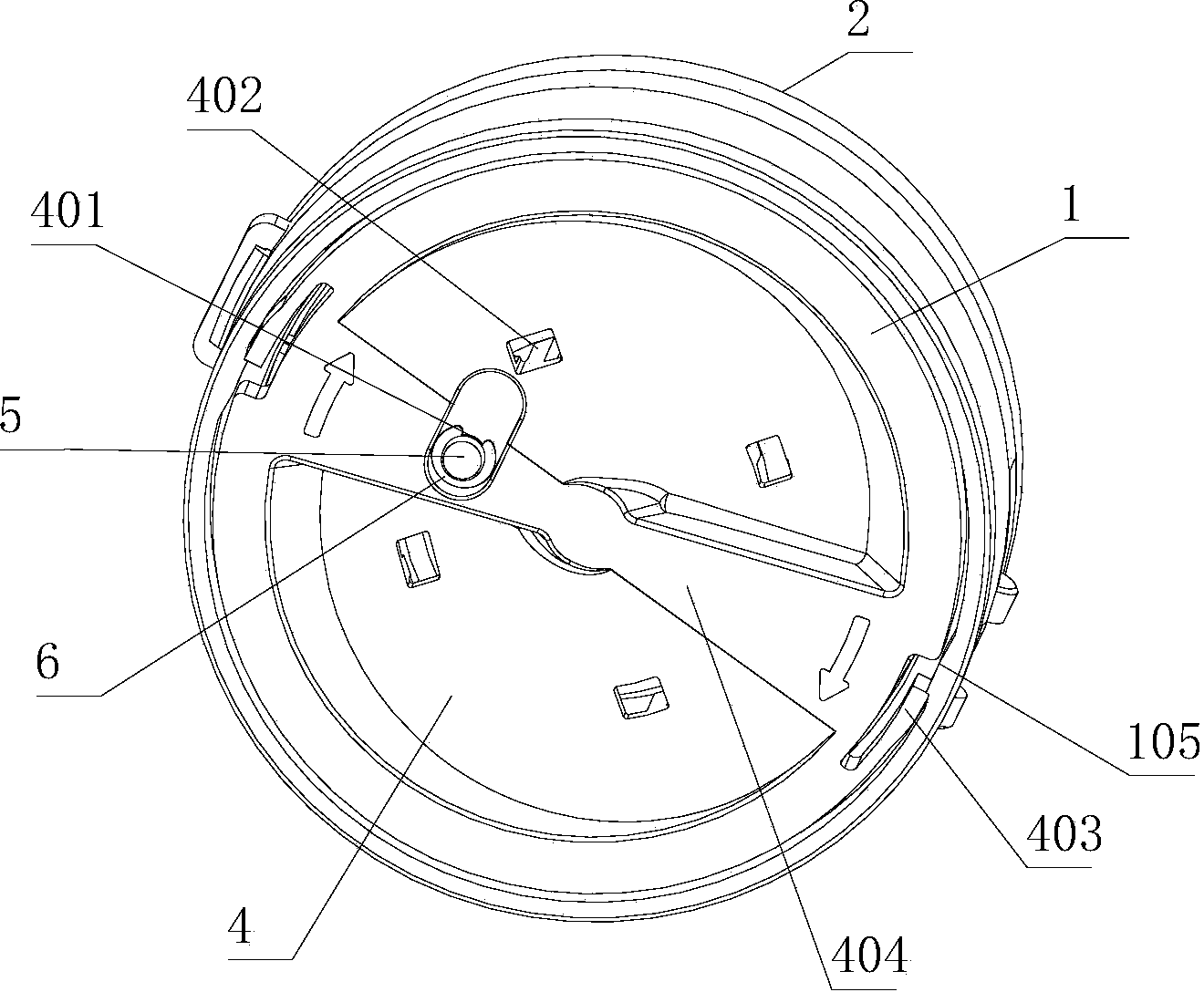

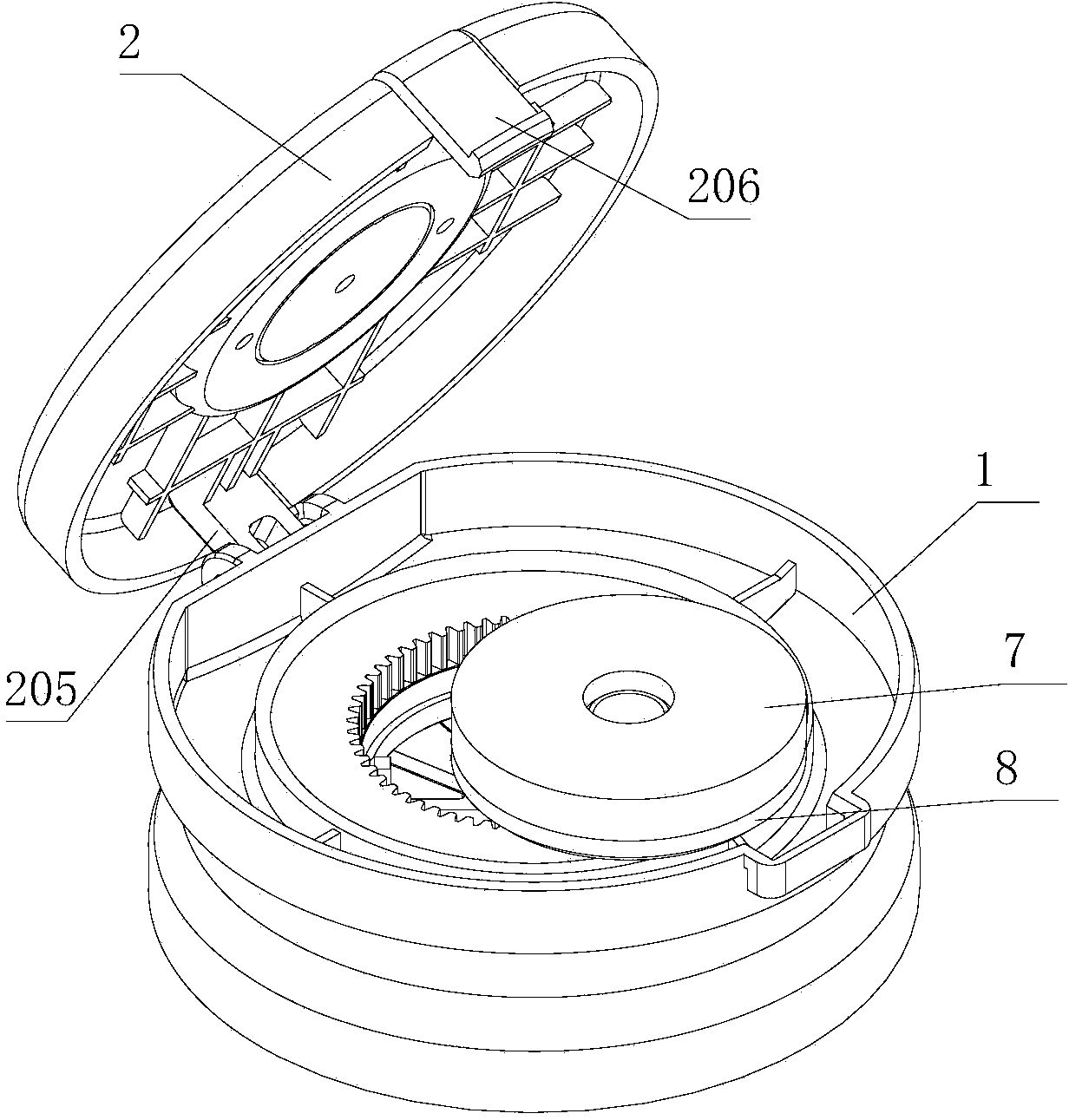

[0035] Such as Figures 1 to 10 Shown is a schematic structural view of the first embodiment of the present invention.

[0036]In this embodiment, an optical fiber end face grinder includes a housing 1, the top of the housing 1 is provided with an optical fiber fixing module 3, the bottom of the housing 1 is provided with a base 4 that can rotate relative to the housing 1, and the base 4 is provided with The eccentric connection part is connected with the transmission shaft 5 that can revolve with the rotation of the base 4. The transmission shaft 5 is set with a pinion 501 with ring-shaped external meshing teeth. The inner side of the housing 1 is provided with a ring-shaped internal meshing Toothed bull gear 101, the transmission shaft 5 rotates by itself under the interaction between the pinion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com