System for conducting dust removal on tail smoke generated when spraying granulation is conducted on chemical fertilizer

A technology for shotcrete granulation and tail smoke, which is used in the separation of dispersed particles, chemical instruments and methods, and liquid droplet granulation. and other problems, to achieve the effect of reducing heat, saving costs, and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

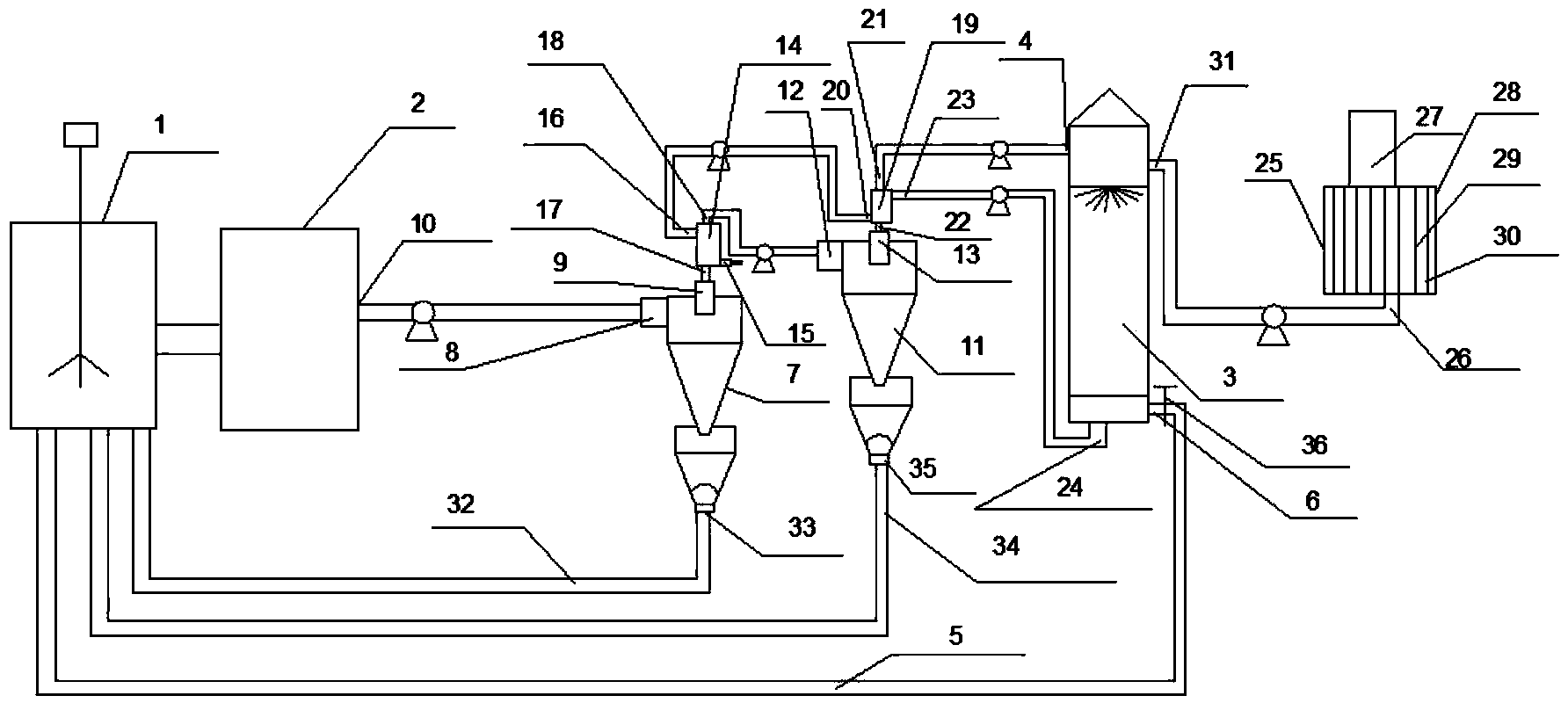

[0030] Such as figure 1 As shown, the present invention provides a system for dedusting tail smoke generated during spray granulation of chemical fertilizers, wherein, after mixing the liquid raw materials and solid raw materials in the stirring tank 1, the slurry formed is passed through the spray granulator 2 It is sprayed out, and then dried and granulated with hot air instantaneously. At this time, dusty tail smoke is generated. The system removes dust from the dusty tail smoke, including:

[0031] A cyclone dust collector, which has an inlet for accessing the dusty tail smoke, and an outlet for discharging the primary clean flue gas after cyclone dust removal;

[0032]The heat exchanger has a liquid raw material inlet and a primary net flue gas inlet, a liquid raw mater...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap