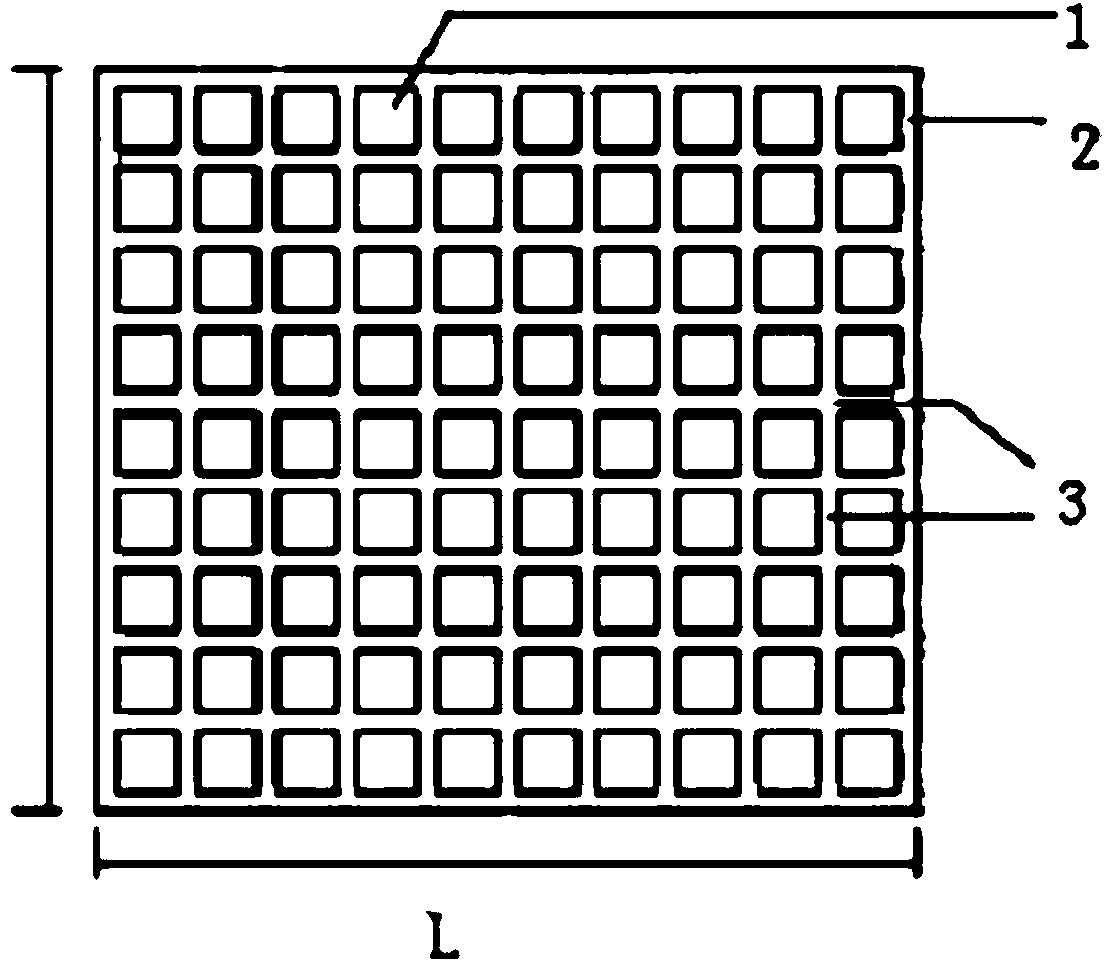

Preparation method of high-vanadium honeycomb type SCR denitration catalyst

A denitrification catalyst, honeycomb technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of adding enough, and achieve easy operation, strong practicability, and large load capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

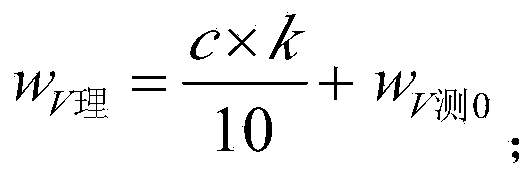

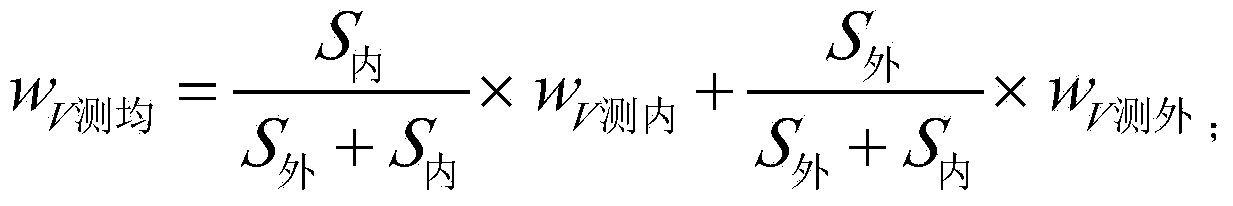

[0029] Select a honeycomb-shaped SCR denitration catalyst monomer after one-time calcination and code it as 1#, and measure its V by XRF 2 o 5 The content is 0.26%. If designing a single V 2 o 5 The content is adjusted to 1.00%, the monomer pore volume of the measured monomer is 0.25cm3 / g, and the formula 1 is used to calculate the V 2 o 5 Concentration is (1.00-0.26) * 10 / 0.25=29.60g / l impregnating liquid. Its concentration is 29.37g / l to detect with spectrophotometer. Continue to follow the method step to completely immerse the monomer in the impregnating liquid for 30 minutes, use The pump maintains a slow and continuous flow of impregnating liquid through the cells' pores. The monomer was taken out, and the remaining impregnating solution on the surface of the catalyst was filtered. The impregnated monomer is put into a drying furnace and a calcination furnace for drying and calcination. After taking out the monomer after calcination, measure the V of its monomer wi...

Embodiment 2

[0031] Select a honeycomb-shaped SCR denitration catalyst monomer after one-time calcination and code it as 2#, and measure its V by XRF 2 o 5 The content is 0.51%. If designing a single V 2 o 5 The content is adjusted to 1.71%, and the pore volume of the monomer is measured to be 0.27cm3 / g, and the formula 1 is used to calculate the V 2 o 5 Concentration of (1.71-0.51) * 10 / 0.26 = 46.15g / l impregnating solution. Prepare 400KG of impregnating solution, and use a spectrophotometer to detect its concentration as 46.58g / l. Continue to completely impregnate the monomer in the impregnating solution according to the method steps For 30 minutes in the liquid, use a pump to keep the impregnating liquid flowing slowly and continuously through the pores of the monomer. The monomer was taken out, and the remaining impregnating solution on the surface of the catalyst was filtered. The impregnated monomer is put into a drying furnace and a calcination furnace for drying and calcinati...

Embodiment 3

[0033] Select a honeycomb-shaped SCR denitration catalyst monomer after one-time calcination and code it as 3#, and measure its V by XRF 2 o 5 The content is 0.51%. If designing a single V 2 o 5 The content is adjusted to 1.90%, the pore volume of the monomer is measured to be 0.31cm3 / g, and the formula 1 is used to calculate the V 2 o 5 Concentration of (1.90-0.51) * 10 / 0.31 = 44.48g / l impregnating liquid. Configure impregnating liquid 400KG, use a spectrophotometer to detect its concentration as 43.94g / l. Continue to completely impregnate the monomer in the impregnating For 30 minutes in the liquid, use a pump to keep the impregnating liquid flowing slowly and continuously through the pores of the monomer. The monomer was taken out, and the remaining impregnating solution on the surface of the catalyst was filtered. The impregnated monomer is put into a drying furnace and a calcination furnace for drying and calcination. Take out the calcined monomer, and use XRF to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com