Preparation method of special fertilizer for cotton

A special cotton fertilizer and preparation method technology, applied in the direction of chemical instruments and methods, application, phosphate fertilizer, etc., can solve the problems of changing soil structure, high labor intensity, etc., and achieve the effects of less fertilizer input, low production cost, and significant environmental protection value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

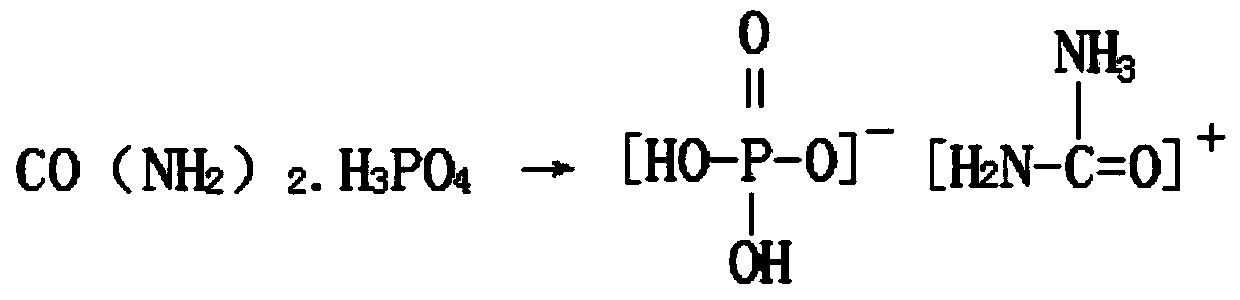

Method used

Image

Examples

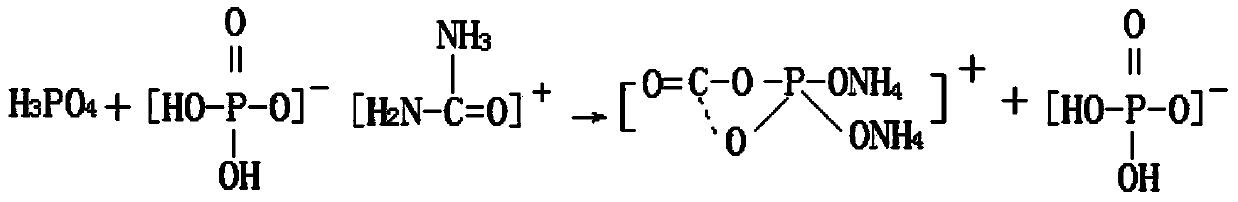

Embodiment 1

[0040] A preparation method of special fertilizer for cotton, adding phosphoric acid and carbonamide into the reactor at a molar ratio of 1.2:1 and mixing them, then raising the temperature of the two mixtures to 120°C at a heating rate of 4°C / min, stirring and reacting 130min, the temperature was cooled to 30°C and then centrifuged to obtain the intermediate; the intermediate and sodium hydroxide were mixed and reacted in the reactor at a molar ratio of 1:0.9, and the stirring speed was 220r / min for 70min. The reaction temperature is 60°C, and the pH value of the reaction is adjusted to 8. After the reaction is completed, a slurry containing nitrogen and phosphorus is obtained, and the slurry is placed in a cooling crystallizer and cooled to 30°C for cyclic crystallization treatment, and the filtrate is detected and analyzed at the same time. When the nitrogen content in the filtrate was 9%, and the phosphorus content was 2.8%, stop crystallization and filter, and the filter c...

Embodiment 2

[0043] A preparation method of special fertilizer for cotton. Phosphoric acid and carbonamide are added into the reactor at a molar ratio of 1.4:1 and mixed, then the temperature of the two mixtures is raised to 150°C at a heating rate of 4°C / min, and the reaction is stirred. After 150 minutes, the temperature was cooled to 40°C and then centrifuged to obtain the intermediate; the intermediate and sodium hydroxide were mixed and reacted in the reactor at a molar ratio of 1:1.1, and the stirring speed was 260r / min for 50 minutes. The reaction temperature is 80°C, and the pH value of the reaction is adjusted to 9. After the reaction is completed, a slurry containing nitrogen and phosphorus is obtained. The slurry is placed in a cooling crystallizer and cooled to 35°C for cyclic crystallization treatment, and the filtrate is detected and analyzed at the same time. When the nitrogen content in the filtrate was 11%, and the phosphorus content was 3.5%, stop crystallization and filte...

Embodiment 3

[0046] A preparation method of special fertilizer for cotton. Phosphoric acid and carbonamide are added to the reaction kettle at a molar ratio of 1.3:1 and mixed, and then the temperature of the two mixtures is raised to 140°C at a heating rate of 4°C / min, and the reaction is stirred. 140min, the temperature was cooled to 35°C and then centrifuged to obtain the intermediate; the intermediate and sodium hydroxide were mixed and reacted in the reactor at a molar ratio of 1:1, and the stirring speed was 240r / min for 60min. The reaction temperature is 70°C, and the pH value of the reaction is adjusted to 8.5. After the reaction is completed, a slurry containing nitrogen and phosphorus is obtained. The slurry is placed in a cooling crystallizer and cooled to 25°C for cyclic crystallization treatment, and the filtrate is detected and analyzed at the same time. When the nitrogen content in the filtrate is 10% and the phosphorus content is 3.1%, stop crystallization and filter, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com