Tempered sponge brick produced by using urban construction garbage by treating waste with waste

A technology that uses waste to treat waste and urban construction waste. It is used in construction waste recycling, furniture waste recycling, and solid waste removal. It can solve problems such as difficult development, high difficulty, and small output, and achieves reduction of self-weight, good energy saving, and improved energy efficiency. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention is described in more detail below through specific embodiments:

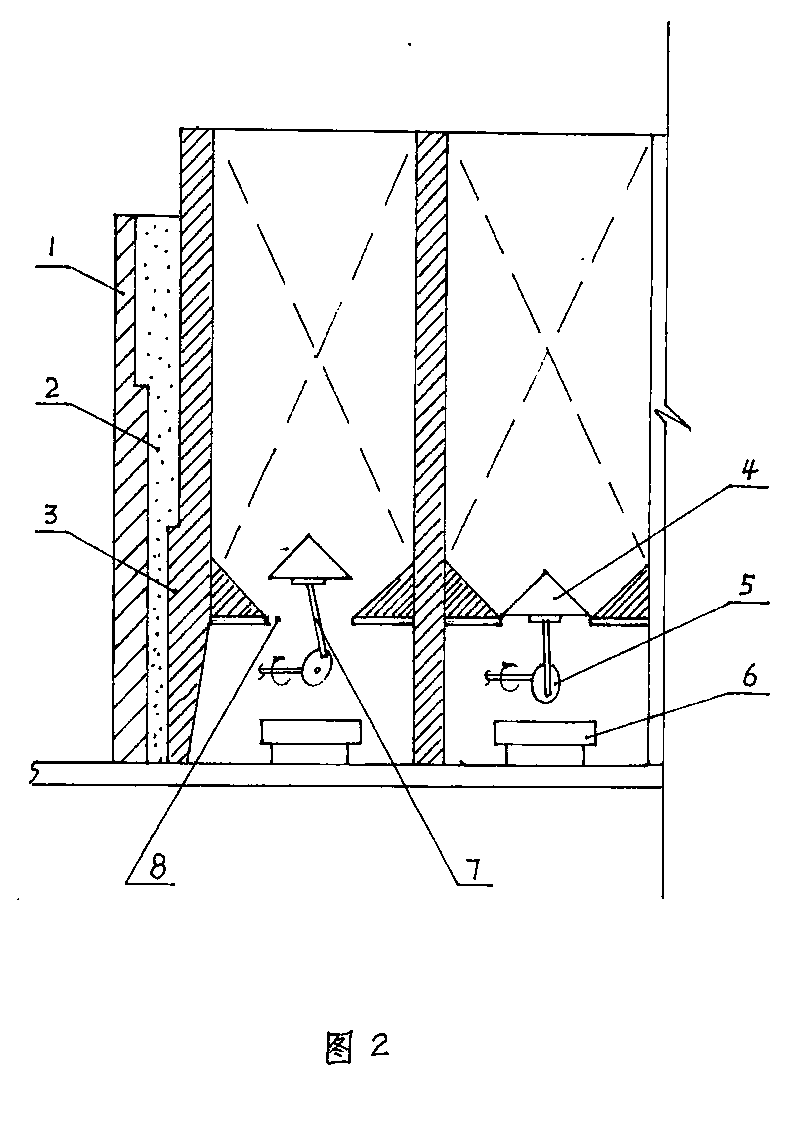

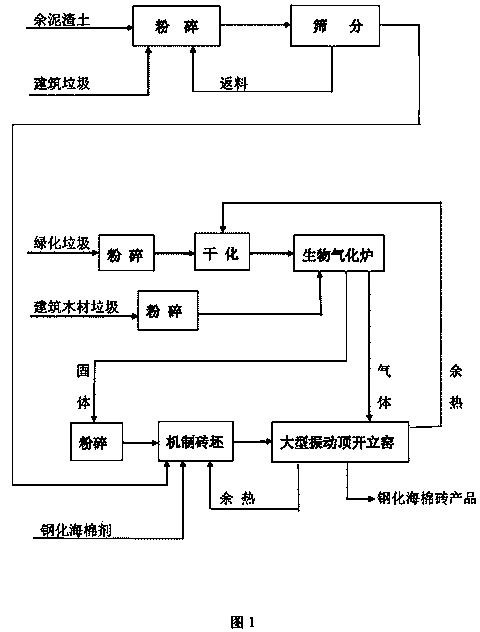

[0024] refer to figure 1~ 2. The method of the present invention for producing tempered sponge bricks from urban construction waste by waste treatment, including raw material crushing, screening, drying, biogasification furnace dry distillation, machine-made bricks and large shaft kiln roasting. The specific production process is as follows: 1. The residual mud excavated by urban construction mainly contains sand, stone and clay, and the construction waste generated by the old city renovation. First remove organic matter such as plastics and wood, and then add 10% to the residual mud. The construction waste is crushed and screened, and the large pieces are used as return materials to be crushed again, and the qualified products after screening can be used as brick base materials. 2. Smash the green waste generated by roads and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com