Method of reinforcing concrete bridge by prestressed steel plates

A concrete and prestressed technology, applied in bridges, bridge materials, bridge maintenance, etc., can solve problems such as bearing capacity decline, unbearable bearing capacity of road bridges, cracks, etc., to improve strength and bearing capacity, prolong service life, and operate The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

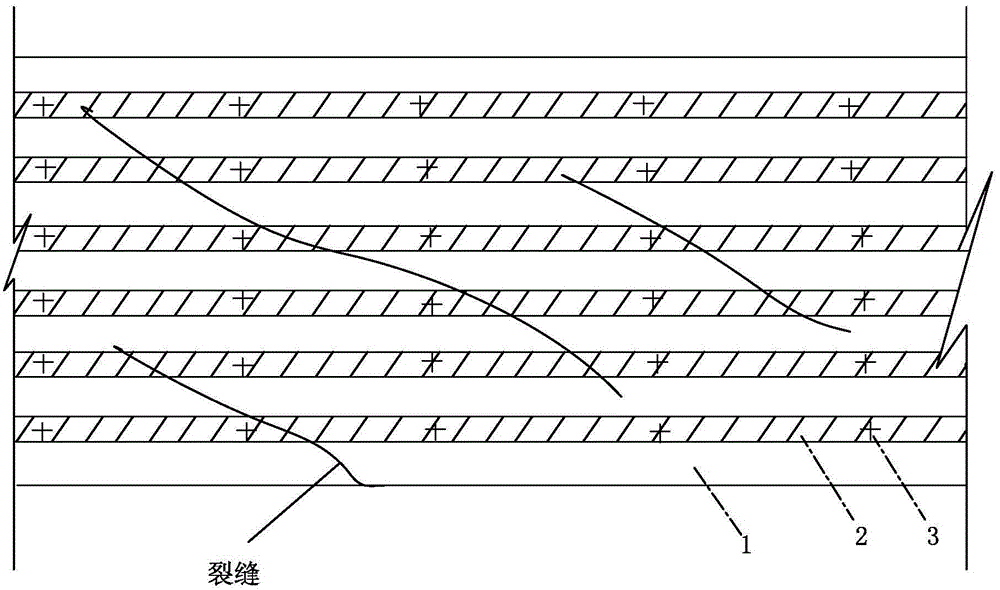

[0042] The box girder of the concrete bridge is reinforced with prestressed steel plates to prevent the expansion of cracks on the box girder.

[0043] 1) According to the requirements of design drawings and on-site measurement and positioning, a large sample is released on the concrete surface of the box girder to be pasted with steel plates, and the depth is chiseled to about 7 mm; then the surface laitance is removed with a wire brush, and the loose matter on the surface is removed, and finally oil-free Blow off the surface dust with compressed air, and wipe the surface with absorbent cotton dipped in acetone.

[0044] 2) Determine the position to be drilled according to the design drawings, and then drill the hole; use compressed air to clean the floating dust in the hole, then clean it with acetone, and pour two-thirds of the hole deep structural glue into the hole; clean the screw with acetone, and then install Anchor screw.

[0045] 3) According to the actual lofting o...

Embodiment 2

[0054] Prestressed steel plates are used to strengthen the two box girders of the concrete bridge to prevent the expansion of the gap between the box girders.

[0055] 1) According to the requirements of the design drawings and on-site measurement and positioning, place a large sample on the surface of the concrete to be reinforced with steel plates, chisel to a depth of about 5 mm; then use a wire brush to remove the floating slurry on the surface, remove loose objects on the surface, and finally rinse with water, wait Wipe the surface with absorbent cotton dampened with acetone after it is completely dry.

[0056] 2) Determine the position to be drilled according to the design drawings, and then drill the hole; use compressed air to clean the floating dust in the hole, then clean it with acetone, and pour two-thirds of the hole deep structural glue into the hole; clean the screw with acetone, and then install Anchor screw.

[0057] 3) According to the actual lofting on the co...

Embodiment 3

[0066] The box girder of the concrete bridge is reinforced with prestressed steel plates to prevent the increase of cracks on the box girder.

[0067] 1) According to the requirements of the design drawings and on-site measurement and positioning, a large sample is released on the concrete surface of the box girder to be pasted with steel plates, and the depth is chiseled to about 6mm; then the surface laitance is removed with a wire brush, and the loose matter on the surface is removed, and finally an oil-free Blow off the surface dust with compressed air, and wipe the surface with absorbent cotton dipped in acetone.

[0068] 2) Determine the position to be drilled according to the design drawings, and then drill the hole; use compressed air to clean the floating dust in the hole, then clean it with acetone, and pour two-thirds of the hole deep structural glue into the hole; clean the screw with acetone, and then install Anchor screw.

[0069] 3) According to the actual loft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com