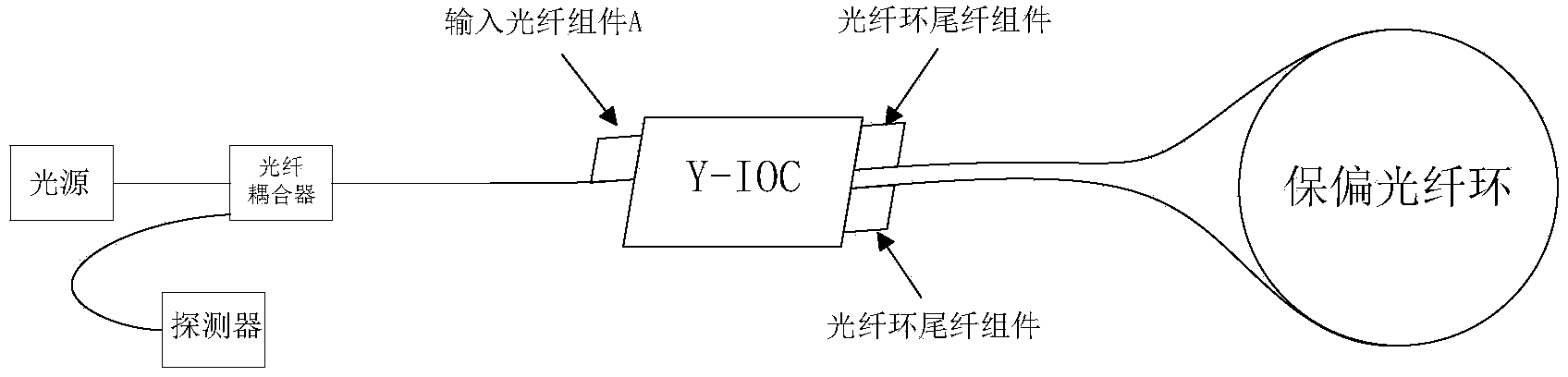

Online detection device and method for polarization axis alignment in direct coupling process of polarization-preserving fiber ring and Y waveguide

A polarization-maintaining optical fiber ring and detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of affecting the axis-to-axis accuracy of the polarization axis, increasing the polarization cross-coupling of the waveguide output channel, and reducing the reliability of the system. Achieve high alignment accuracy and improve the effect of shaft alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

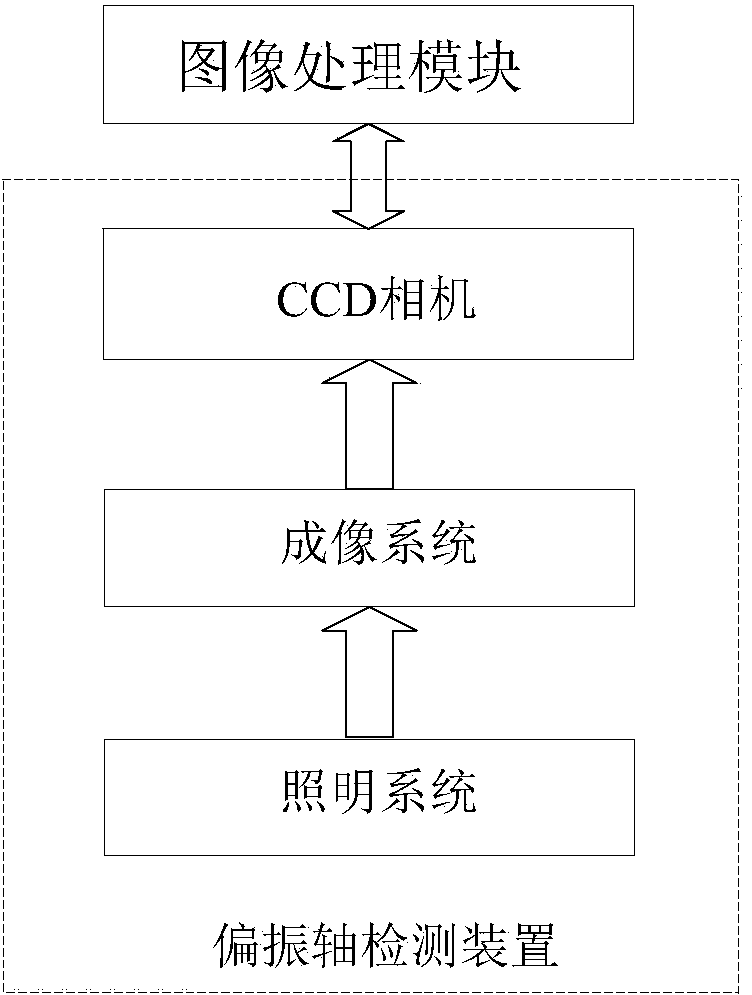

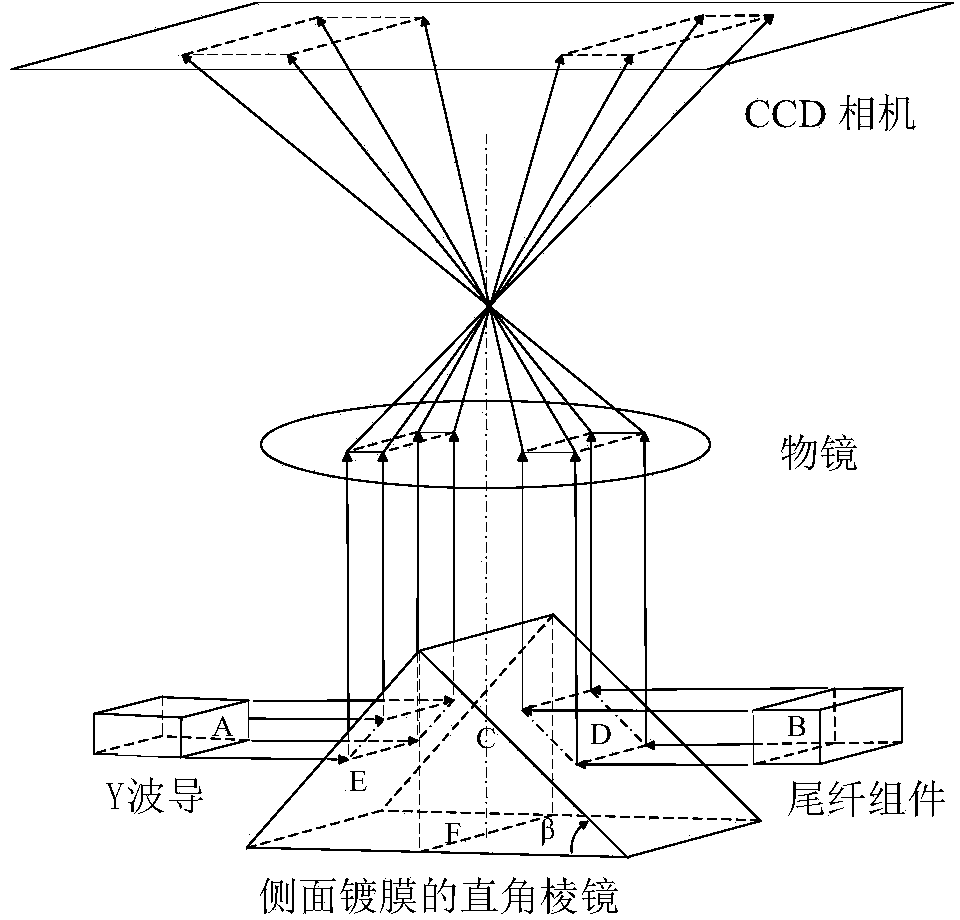

[0056] The specific structure of the imaging system is as follows: image 3 As shown, as follows:

[0057] The reflective optical element is a high-precision right-angle prism coated with a high-reflection film, which can be replaced by a rotating mirror or a double-sided mirror, which plays the role of refracting the optical axis.

[0058] When building the optical path of the polarization axis detection device, the Y waveguide, the polarization-maintaining fiber ring pigtail assembly, the imaging system and the CCD camera are coaxially arranged. The specific settings are: the right-angle prism is placed between the end face A of the Y waveguide and the end face B of the pigtail assembly of the polarization-maintaining fiber ring, with the bottom surface F of the right-angle prism as the reference plane, the reference plane C of the right-angle prism is perpendicular to the bottom surface F of the prism, and the reference plane C Keep parallel to the end face A of the Y-wave...

Embodiment 2

[0071] The rectangular prism is replaced by a double-sided mirror, and the specific structure is as follows:

[0072] like Figure 4 As shown, the Y waveguide, the polarization-maintaining fiber ring pigtail assembly and the double-sided reflector are coaxially arranged. The double-sided reflector is placed between the two ends of the Y-waveguide and the polarization-maintaining fiber ring pigtail assembly. The two working surfaces correspond to The end face of the Y waveguide and the end face of the polarization-maintaining fiber ring pigtail assembly; two sets of objective lenses are used to image the end face of the Y waveguide and the end face of the polarization-maintaining fiber ring pigtail assembly respectively, wherein each objective lens corresponds to a CCD camera, and the two CCD cameras are respectively It is used to collect images of two end faces, and transmit the collected images of both end faces to the computer for processing.

[0073] Specifically, the ligh...

Embodiment 3

[0077] The rectangular prism is replaced by a rotating mirror, and the specific structure is as follows:

[0078] like Figure 5 As shown, the Y waveguide, the polarization maintaining fiber ring pigtail assembly and the rotating mirror are coaxially arranged, and the rotating mirror is placed between the two ends of the Y waveguide and the polarization maintaining fiber ring pigtail assembly; the working surface of the rotating mirror is a single reflecting surface , its rotation center line is perpendicular to the coaxial line connecting the center of the Y waveguide and the pigtail assembly of the polarization-maintaining fiber ring; the reflective surface has two position states of 1 and 2, and it is rotated by 90 from the other position state ° Obtained; respectively used to reflect the images of the Y waveguide end face and the polarization maintaining fiber ring pigtail assembly end face to the objective lens.

[0079] When the mirror is rotated to position 1, the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com