Single-mold-cavity microwave thermogravimetric analysis system

A thermogravimetric analysis, single-mode cavity technology, applied in the direction of removing certain components for weighing, preparation of test samples, etc., can solve the problems affecting the measurement accuracy of the instrument, affecting the test results, and the zero drift of the mass sensor, etc. To achieve the effect of easy viewing and copying of data, good product uniformity, and high microwave utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

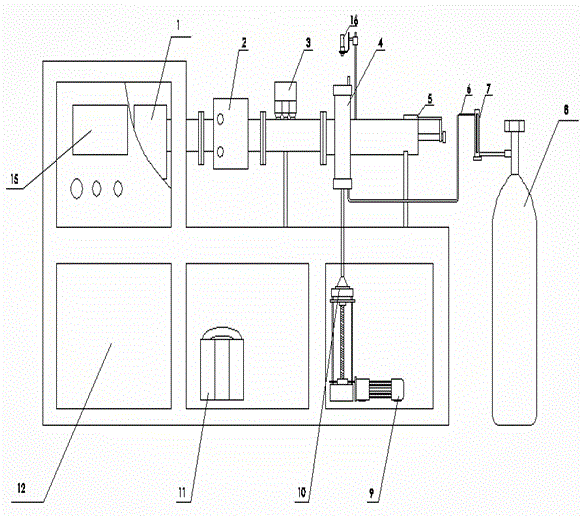

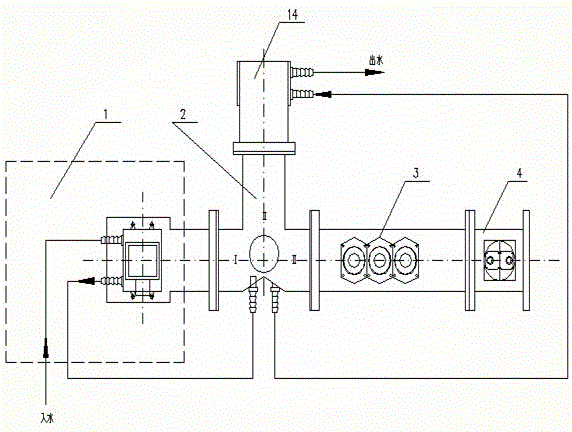

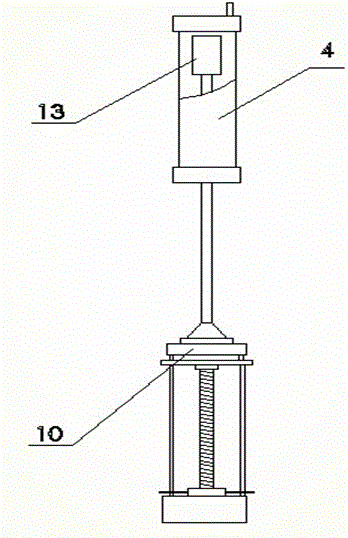

[0055] Such as Figures 1 to 3 As shown, the single-mode cavity microwave thermogravimetric analysis system includes an electric cabinet 12, a microwave source, a microwave reactor, a microwave transmission system, a PLC control system, a quality measurement system, a temperature measurement system and an atmosphere adjustment system;

[0056] The electric cabinet 12 is divided into a cabinet body standing on the ground and a cabinet head on the upper surface of one end of the cabinet body, and the electric cabinet 12 provides electric energy for the thermogravimetric analysis system;

[0057] Described microwave source comprises magnetron 1, and magnetron is installed in electric cabinet 12 cabinets inside;

[0058] The microwave reactor uses a single-mode quartz tube reaction chamber 4 as a reaction chamber, and the single-mode quartz tube reaction chamber 4 is divided into two layers, the outer layer is a copper tube, the inner layer is a quartz glass tube, and the outer la...

Embodiment 2

[0066] Such as Figures 1 to 3 As shown, the single-mode cavity microwave thermogravimetric analysis system includes an electric cabinet 12, a microwave source, a microwave reactor, a microwave transmission system, a PLC control system, a quality measurement system, a temperature measurement system and an atmosphere adjustment system;

[0067] The electric cabinet 12 is divided into a cabinet body standing on the ground and a cabinet head on the upper surface of one end of the cabinet body, and the electric cabinet 12 provides electric energy for the thermogravimetric analysis system;

[0068] Described microwave source comprises magnetron 1, and magnetron is installed in electric cabinet 12 cabinets inside;

[0069] The microwave reactor uses a single-mode quartz tube reaction chamber 4 as a reaction chamber, and the single-mode quartz tube reaction chamber 4 is divided into two layers, the outer layer is a copper tube, the inner layer is a quartz glass tube, and the outer la...

Embodiment 3

[0077] Such as Figures 1 to 3 As shown, the single-mode cavity microwave thermogravimetric analysis system includes an electric cabinet 12, a microwave source, a microwave reactor, a microwave transmission system, a PLC control system, a quality measurement system, a temperature measurement system and an atmosphere adjustment system;

[0078] The electric cabinet 12 is divided into a cabinet body standing on the ground and a cabinet head on the upper surface of one end of the cabinet body, and the electric cabinet 12 provides electric energy for the thermogravimetric analysis system;

[0079] Described microwave source comprises magnetron 1, and magnetron is installed in electric cabinet 12 cabinets inside;

[0080] The microwave reactor uses a single-mode quartz tube reaction chamber 4 as a reaction chamber, and the single-mode quartz tube reaction chamber 4 is divided into two layers, the outer layer is a copper tube, the inner layer is a quartz glass tube, and the outer la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com