Laser in-situ detection system for oxygen concentration in arsenic-bearing gold concentrate roasting furnace

An oxygen concentration and in-situ detection technology, which is applied in the field of laser spectrum detection of gas concentration, can solve problems such as a large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0064] The oxygen concentration laser in-situ detection system provided by the present invention will be described in detail below by taking an arsenic-containing gold concentrate roaster with an absolute temperature ranging from 296K to ~1500K as an example.

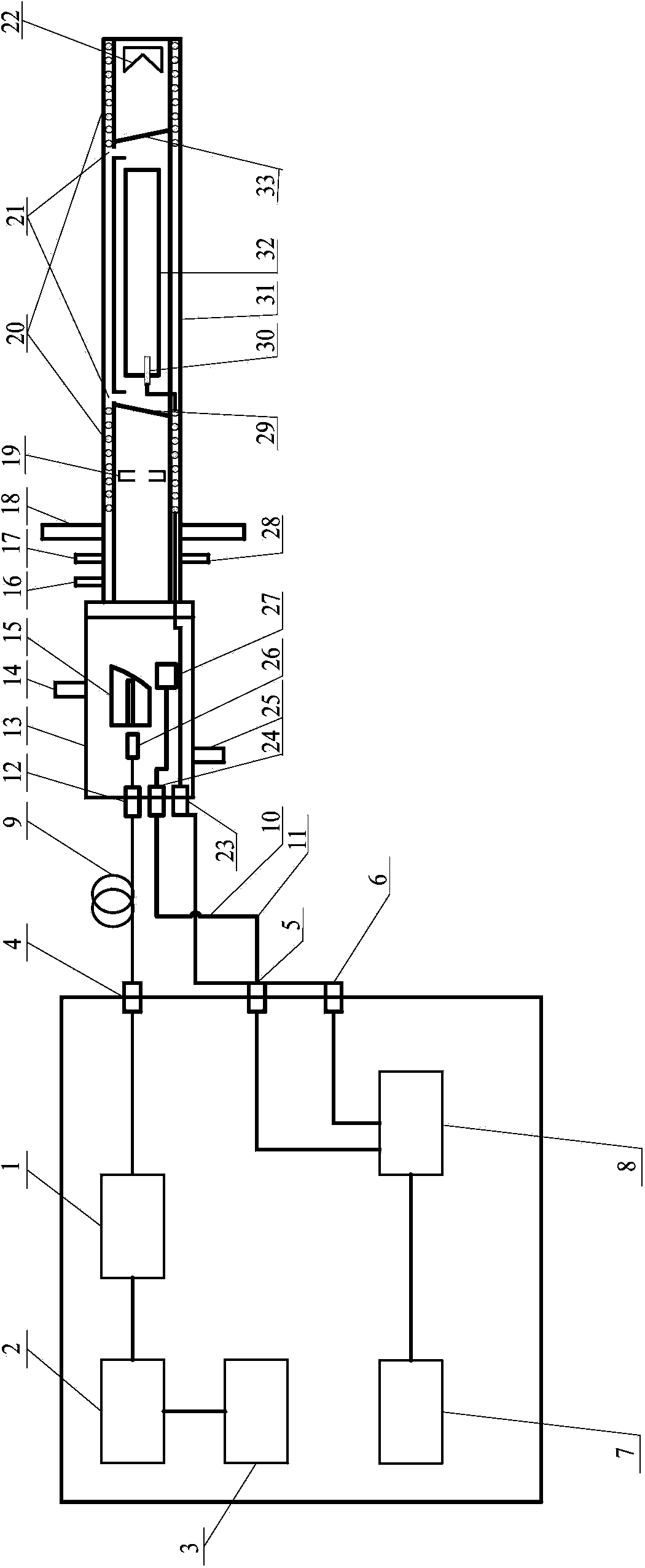

[0065] see figure 1 , the system mainly includes a semiconductor laser 1, a temperature and current controller 2 for driving the semiconductor laser, a signal generator 3 for generating a driving signal, an optical probe for receiving and converting the laser beam, and for collecting Temperature and pressure sensor 30, a data acquisition module 8 for receiving and collecting photoelectric, temperature and pressure signals, and a host computer 7 for calculating and detecting oxygen concentration, wherein,

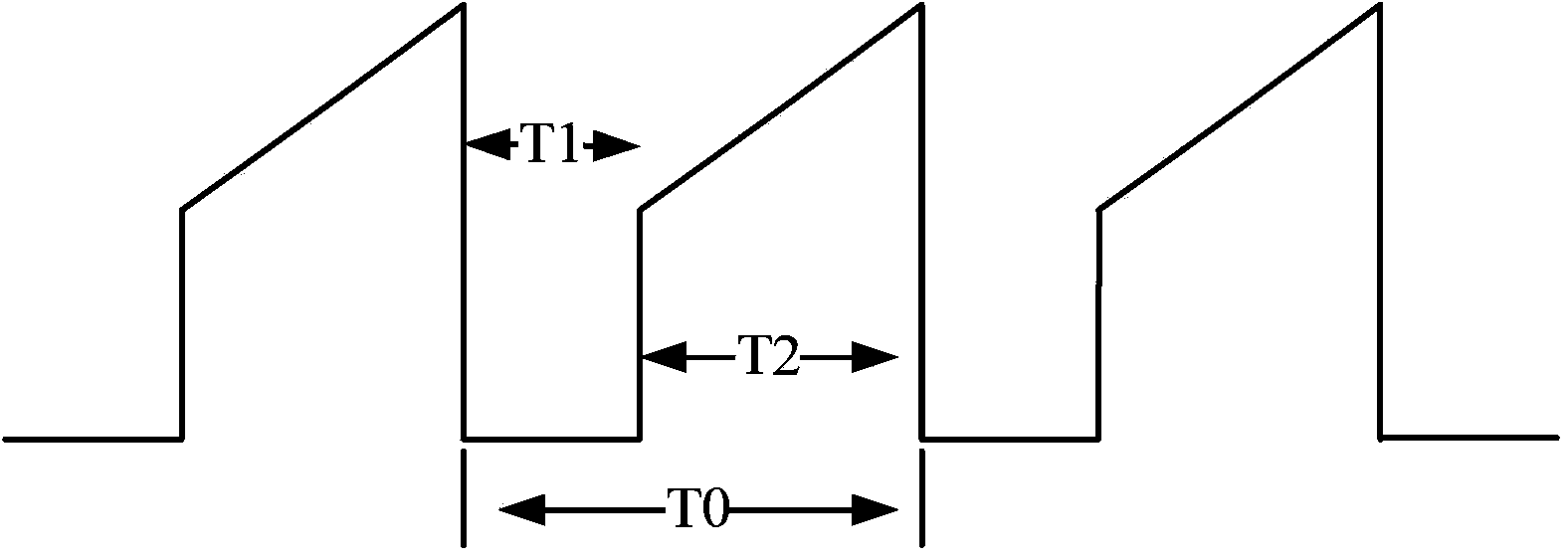

[0066] The semiconductor laser 1 is a fiber-coupled near-infrared distributed semiconductor laser with a center wavelength of 768nm. Its output laser beam is output to the fiber coupler 12 of the optical probe through...

example 2

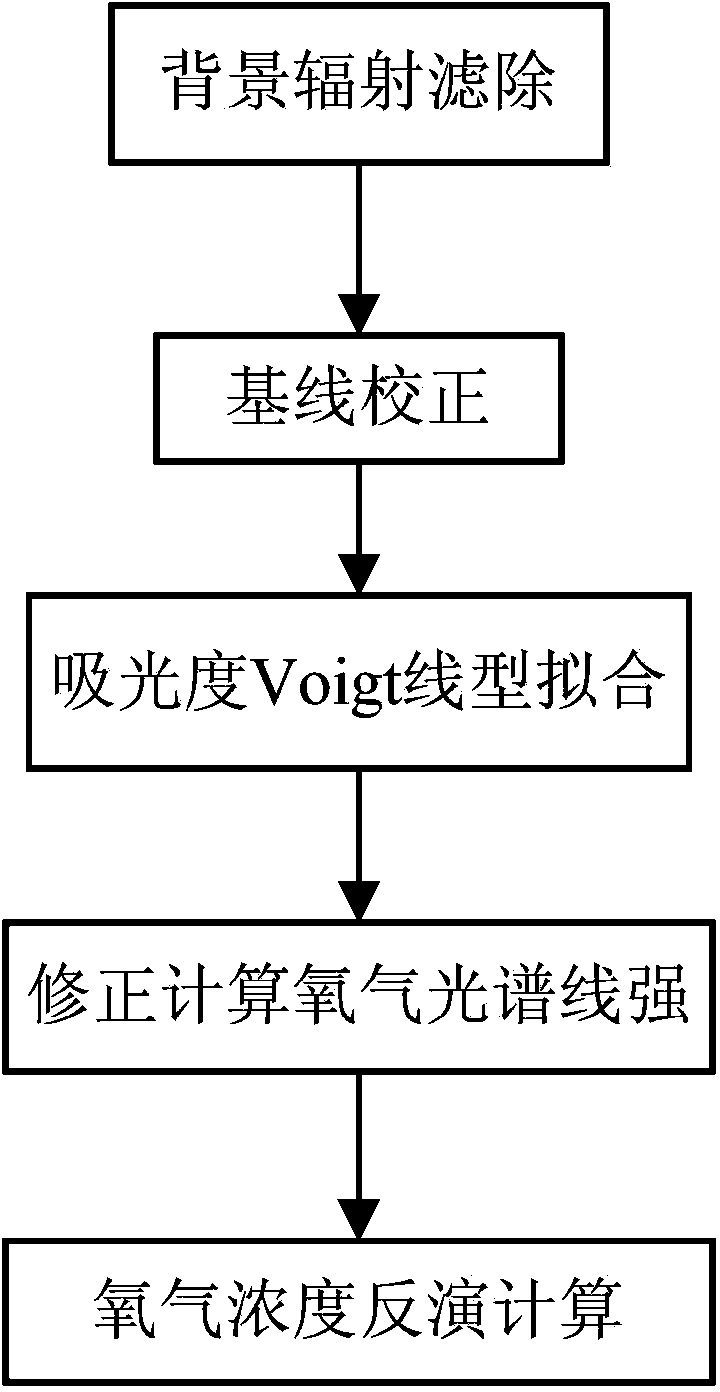

[0098] In order to verify the effect of the method of the present invention, this example respectively adopts the fitting function model constructed by the prior art based on the Gauss-Hermitian integral and the fitting function model provided by the present invention to use the temperature in the system described in Example 1. Under the conditions of 1000°C and 10% oxygen concentration, the oxygen concentration data in the arsenic-gold concentrate roaster were obtained, and the absorbance Voigt line shape fitting was carried out, and the Levenberg-Marquardt algorithm was used for iterative calculation. When the fitting function model constructed by special integral is used for Levenberg-Marquardt iterative calculation, the initial value of absorbance A 0 Select the integrated value of absorbance. The data obtained are shown in the table below:

[0099]

[0100] Compared with the above table, Figure 5 and Figure 6 It can be seen that the number of iterations when using...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com