A reflective polarized light-enhancing diffusion composite film

A diffusion composite and reflective technology, applied in the direction of optics, optical components, diffusion components, etc., can solve the problems of reduced viewing angle, increased frontal brightness, complex process, etc., to achieve excellent bonding and adhesion, and simplify the manufacturing process , the effect of reduced process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

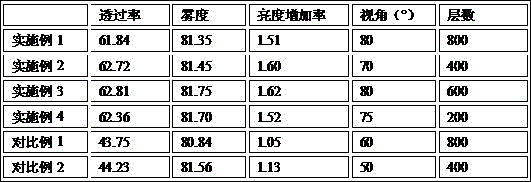

Embodiment 1

[0033] Put dimethyl naphthalene dicarboxylate and ethylene glycol in the macromolecular polymerization reactor, and it is the first resin that 100 mol% of naphthalene dicarboxylate repeating unit is manufactured by condensation polymerization; In the macromolecular polymerization reactor Put dimethyl naphthalate, ethylene glycol, and terephthalic acid separately, and produce ethylene terephthalate with a repeating unit of ethylene naphthalate of 40 mol% by condensation polymerization as described above. The repeating unit is 60 mole % of the second resin. The produced first resin was dried at 100° C. for 24 hours to remove water by a dryer, and the second resin was dried at 70° C. for 48 hours to remove water. The first resin and the second resin were respectively produced 4 layers through the feedblock method at a rate of 30kg / hr, and then passed through the compound multiplier to finally produce an 800-layer extruded film. The manufactured multilayer extruded film was uniax...

Embodiment 2

[0037] Put dimethyl naphthalate, ethylene glycol, and terephthalic acid in a polymer polymerization reactor, and produce ethylene terephthalate with a repeating unit of 90 mol% of ethylene terephthalate through condensation polymerization. Alcohol ester repeating unit is the first resin of 10 mol %; Put dimethyl naphthalate, ethylene glycol, terephthalic acid respectively in the macromolecular polymerization reactor, manufacture naphthalene dicarboxylate by condensation polymerization as mentioned above The second resin containing 60 mol % of ethylene glycol formate repeating units and 40 mol % of ethylene terephthalate repeating units. The produced first resin was dried at 100° C. for 24 hours to remove water by a dryer, and the second resin was dried at 70° C. for 48 hours to remove water. The first resin and the second resin were respectively produced 4 layers through the feedblock method at a rate of 30kg / hr, and then passed through the compound multiplier to finally produ...

Embodiment 3

[0041] Put dimethyl naphthalate, ethylene glycol, and terephthalic acid in a polymer polymerization reactor, and produce hexylene naphthalate repeating unit of 80 mole %, ethylene terephthalate through condensation polymerization. Alcohol ester repeating unit is the first resin of 20 mol %; Put dimethyl naphthalate, ethylene glycol, terephthalic acid respectively in the macromolecular polymerization reactor, manufacture naphthalene dicarboxylate by condensation polymerization as mentioned above The second resin containing 50 mol % of ethylene glycol formate repeating units and 50 mol % of ethylene terephthalate repeating units. The produced first resin was dried at 100° C. for 24 hours to remove water by a dryer, and the second resin was dried at 70° C. for 48 hours to remove water. The first resin and the second resin were respectively produced 4 layers through the feedblock method at a rate of 30kg / hr, and then passed through the compound multiplier to finally produce a 600-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com