Standard high-pressure ionization chamber and manufacturing method thereof

A high-pressure, ionization chamber technology, used in circuits, discharge tubes, electrical components, etc., can solve problems such as unsuitability for standard ionization chambers and measurement results errors, and achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The above and other technical features and advantages of the present invention will be described in more detail below with reference to the accompanying drawings.

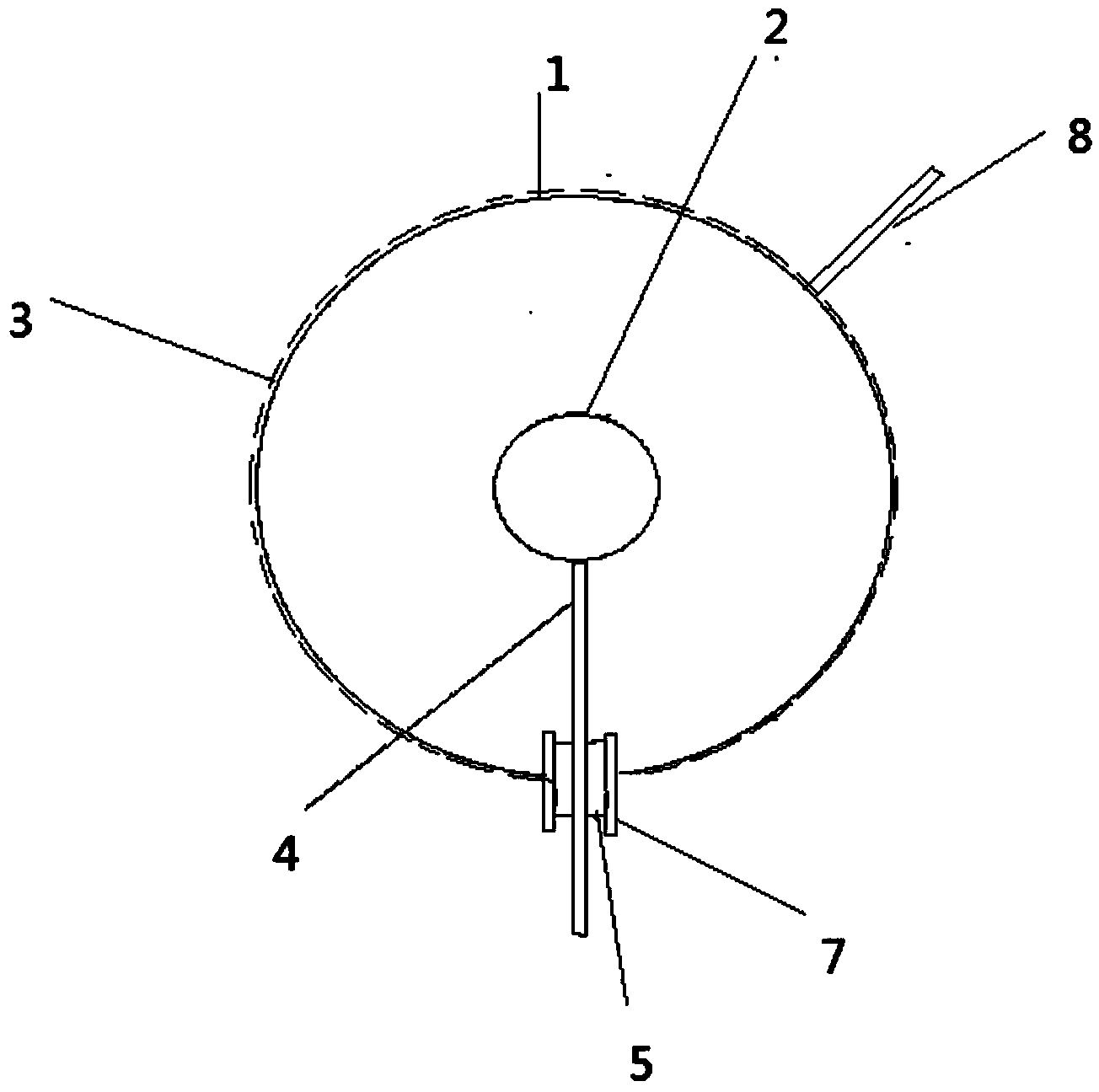

[0034] see figure 1 , is a schematic structural diagram of the high-pressure ionization chamber probe of the standard high-pressure ionization chamber of the present invention, the standard-type high-pressure ionization chamber includes a high-pressure ionization chamber probe, and the high-pressure ionization chamber probe includes a stainless steel shell 1, a stainless steel sphere 2, Compensation sheet 3 , stainless steel support column 4 and insulating terminal 5 .

[0035] The stainless steel shell 1 is a hollow sphere formed by two hemispheres through argon arc welding. As a high-voltage electrode, the stainless steel sphere 2 is located in the center of the stainless steel shell 1. The terminal 5 is connected, and the insulating terminal 5 is welded to the stainless steel housing through the flange. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com