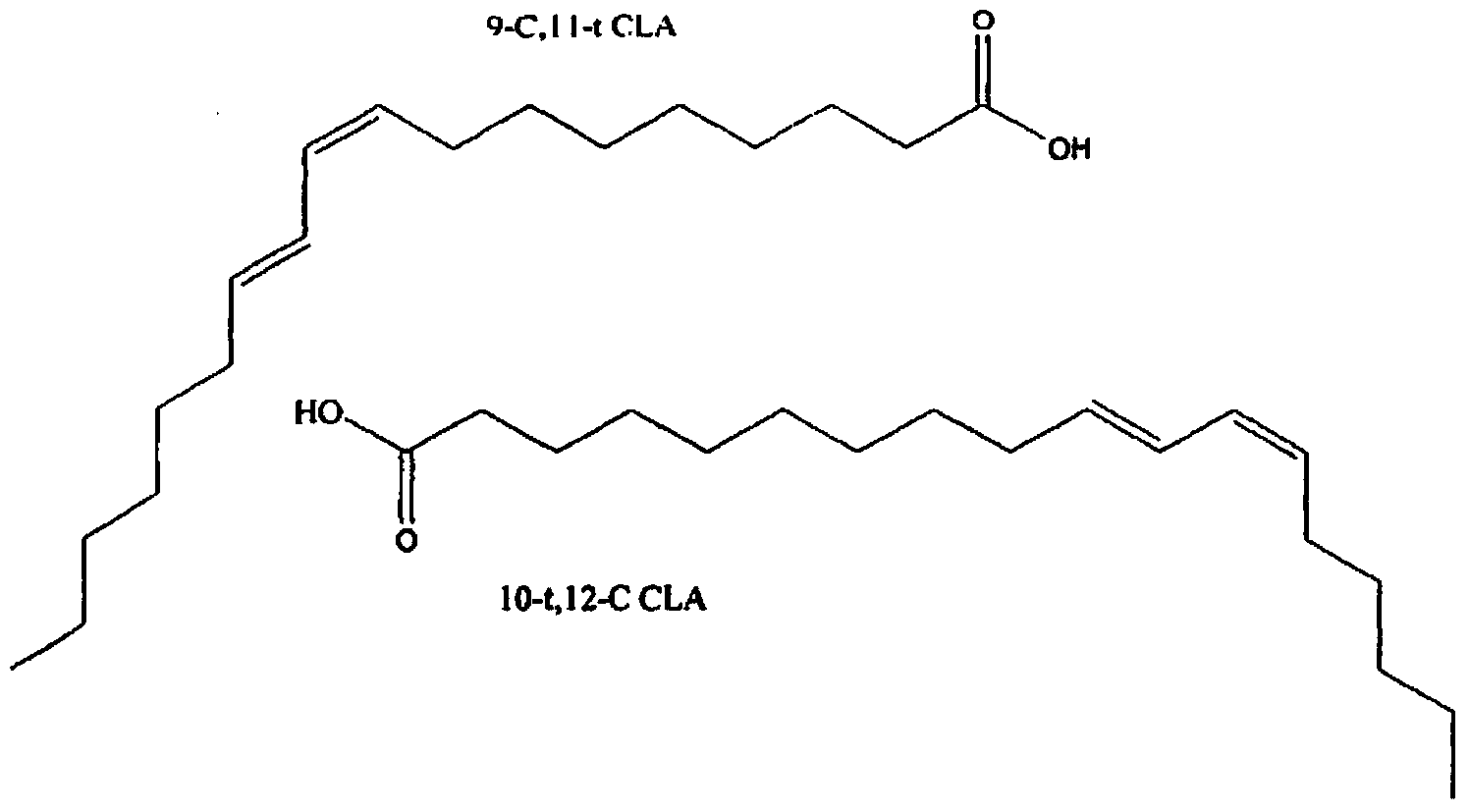

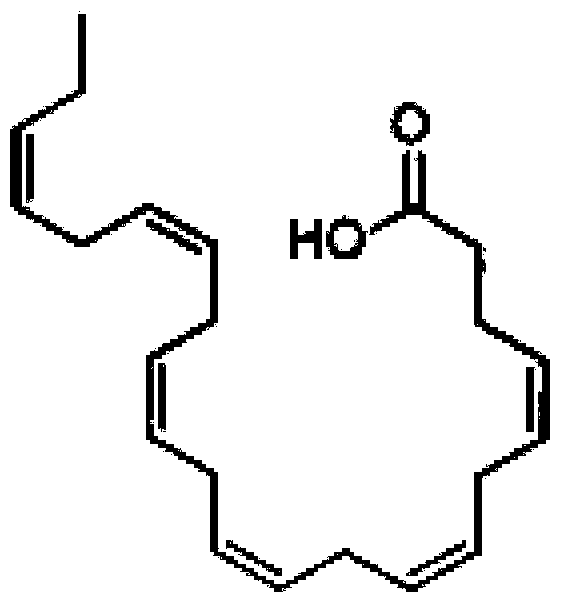

Conjugated linoleic acid and docosahexenoic acid microencapsulated powder, and preparation method and application thereof

A technology of docosahexaenoic acid and conjugated linoleic acid, applied in the field of conjugated linoleic acid and docosahexaenoic acid microencapsulated powder, can solve inconvenience, water insolubility, unfavorable storage, Transportation and application issues, to achieve the effect of simple product formula, enhanced antioxidant properties, enhanced memory and thinking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] a First prepare wall material aqueous solution

[0052] Prepare the wall material solute according to the ratio of gum arabic: maltodextrin = 1:1, then dissolve the solute in water at 70°C, adjust the pH to 6.5, stir for 30 minutes, and prepare a wall material aqueous solution with a concentration of 20%;

[0053]b press conjugated linoleic acid: the ratio of docosahexaenoic acid=5:2 to prepare the capsule core material, and add the capsule core material to the wall material in a ratio of 10:20 by the mass ratio of the capsule core material and the wall material solute In the aqueous solution, stir, add the additive sodium alginate that accounts for 0.2% of the total mass ratio of the capsule core material and the wall material solute, and account for 0.3% of the surfactant fatty acid glyceride in the total mass ratio of the capsule core material and the wall material solute, stir Finally, carry out homogeneous emulsification with a homogenizer at 60°C under a pressure ...

Embodiment 2

[0056] a First prepare wall material aqueous solution

[0057] Prepare the wall material solute according to the ratio of gum arabic:modified starch=1:1, then dissolve the solute in water at 65°C, adjust the pH=6.3, stir for 30 minutes, and prepare a wall material aqueous solution with a concentration of 18%;

[0058] b Press the ratio of conjugated linoleic acid: docosahexaenoic acid=1:1 to prepare the capsule core material, and add the capsule core material to the wall material aqueous solution according to the mass ratio of the capsule core material and the wall material solute of 15:20 In, stir, add and account for capsule core material and wall material solute total mass ratio and add the auxiliary agent sodium alginate that accounts for capsule core material and wall material solute total mass ratio and be 2% surfactant fatty acid glyceride, after stirring Carry out homogeneous emulsification with a homogenizer at 70°C under a pressure of 25MPa, and the emulsification ti...

Embodiment 3

[0061] a First prepare wall material aqueous solution

[0062] Prepare the wall material solute according to the ratio of soybean protein isolate: maltodextrin: xanthan gum = 2:1:0.25, then dissolve the solute in water at 68°C, adjust the pH to 6.8, stir for 30 minutes, and prepare a concentration of 30%. The wall material aqueous solution; b presses conjugated linoleic acid: the ratio of docosahexaenoic acid=2:1 prepares capsule core material, by the ratio of the mass ratio of capsule core material and wall material solute 10:20 the capsule core The substances were added into the aqueous solution of the wall material, stirred, and the auxiliary agent sodium alginate was added to account for 0.15% of the total mass ratio of the capsule core material and the wall material solute, and the surfactant was added to account for 1.2% of the total mass ratio of the capsule core material and the wall material solute. Fatty acid sorbide, after stirring, carry out homogenization and emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com