Starch capsule having moisturizing capability and preparation method thereof

A technology for starch capsules and capabilities, applied in the field of starch capsules and their preparation, can solve the problems of easy water loss and become brittle, poor moisture retention, etc., and achieve the effects of good moisture retention, lower extrusion temperature, and good friability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

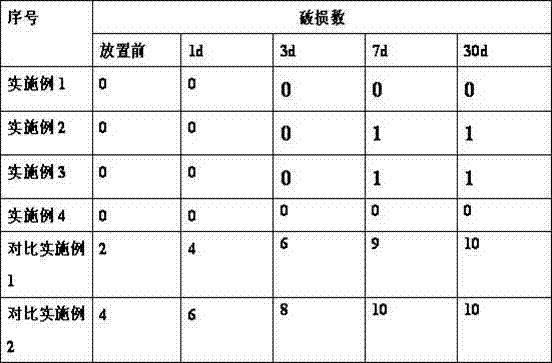

Examples

Embodiment 1

[0055] Straight cornstarch 45kg

[0056] Amylopectin tapioca starch 40kg

[0057] Hydroxypropyl starch 10kg

[0058] Booster 5kg, including:

[0059] Glycerin 0.5kg;

[0060] Carboxymethyl cellulose 1kg;

[0061] Micropowder silica gel 2kg;

[0062] Microcrystalline cellulose 1.25kg;

[0063] Sodium alginate 0.75kg;

[0064] The above components were ground and mixed in a grinder for 30 minutes, then put into a gelatinization pot, added water, stirred and heated to 60°C for pre-gelatinization. Control the temperature to 55°C, stir for 1.5h, and take a sample to check the viscosity to be 250 mPa·s. Let it stand for defoaming for 30 minutes, then control the temperature to 50°C, and send it to the capsule machine to produce 1000 capsule shells by dipping glue.

Embodiment 2

[0066] Amylose corn starch 42.5kg

[0067] Amylopectin potato starch 42.5kg

[0068] Starch nanocrystals 5kg

[0069] Hydroxyethyl starch 5kg

[0070] Booster 5kg, including:

[0071] Glycerin 0.5kg;

[0072] Carboxymethyl cellulose 1kg;

[0073] Micropowder silica gel 2kg;

[0074] Microcrystalline cellulose 1.25kg;

[0075] Sodium alginate 0.75kg;

[0076] The above components were ground and mixed in a grinder for 30 minutes, then put into a gelatinization pot, added water, stirred and heated to 60°C for pre-gelatinization. Control the temperature to 55°C, stir for 1.5h, and take a sample to check the viscosity to be 250 mPa·s. Let it stand for defoaming for 30 minutes, then control the temperature to 50°C, and send it to the capsule machine to produce 1000 capsule shells by dipping glue.

Embodiment 3

[0078] Continuous metering in the feed hopper:

[0079] Direct Pea Starch 70kg / h

[0080] Amylopectin glutinous rice starch 20kg / h

[0081] Sulfate starch 5kg / h

[0082] Enhancer 5kg / h, including:

[0083] Glycerin 1.5kg / h;

[0084] Carboxymethyl cellulose 0.3kg / h;

[0085] Micropowder silica gel 2.5kg / h;

[0086] Microcrystalline cellulose 0.5kg / h;

[0087] Sodium alginate 0.2kg / h;

[0088] The temperature setting of each heating block of the twin-screw extruder is as follows:

[0089] Slider 1: 25°C

[0090] Slider 2-3: 50°C

[0091] Sliders 4-6: 55°C

[0092] Sliders 7-9: 70°C

[0093] Slider 10-12: 80°C

[0094] Nozzle: 80°C

[0095] The position of slider 1 is the hopper, where direct pea starch and amylopectin glutinous rice starch are added, pure water is added at the position of slider 3 at a flow rate of 45kg / h, and various enhancers are added at the position of slider 4. A 0.3 mm sheet was extruded at a speed of 300 rpm. The flakes are fed into a rotar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com