Method and apparatus for manufacturing continuous fiber reinforced material

A technology of continuous fibers and reinforcing materials, applied in the field of manufacturing continuous fiber reinforcing materials, can solve the problems of long impregnation time of fibers, and achieve the effect of reducing impregnation time, good compatibility effect and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the method for manufacturing continuous fiber reinforced material, this method comprises the steps:

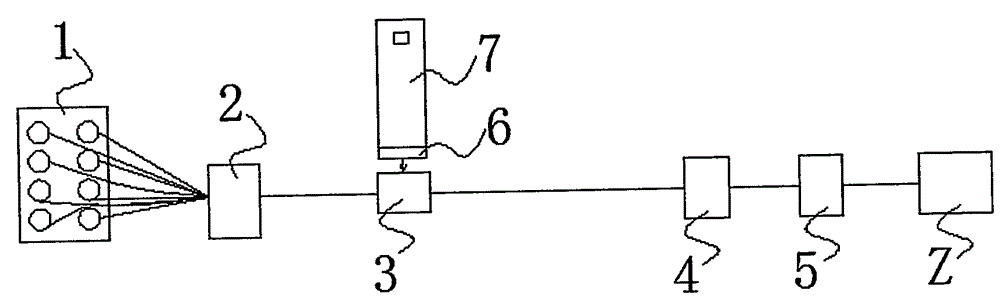

[0041] Step 1, the continuous fiber on the creel 1 is drawn to the untwisting machine 2 through the tractor 4, and the continuous fiber includes inorganic continuous fiber, metal fiber, such as carbon fiber, glass fiber, basalt fiber, boron fiber, silicon carbide fiber, Copper fiber, stainless steel fiber, iron fiber, nickel fiber or a combination of at least two fibers, the fiber diameter is 3 μm to 40 μm, such as 5 μm, 10 μm, 15 μm, etc., and the number of fiber bundles is 100 to 50,000 .

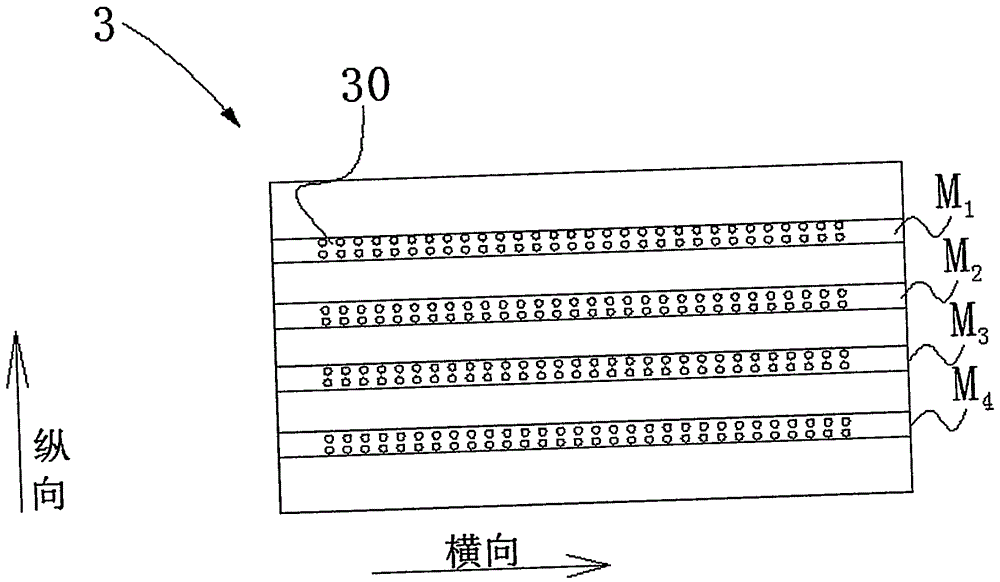

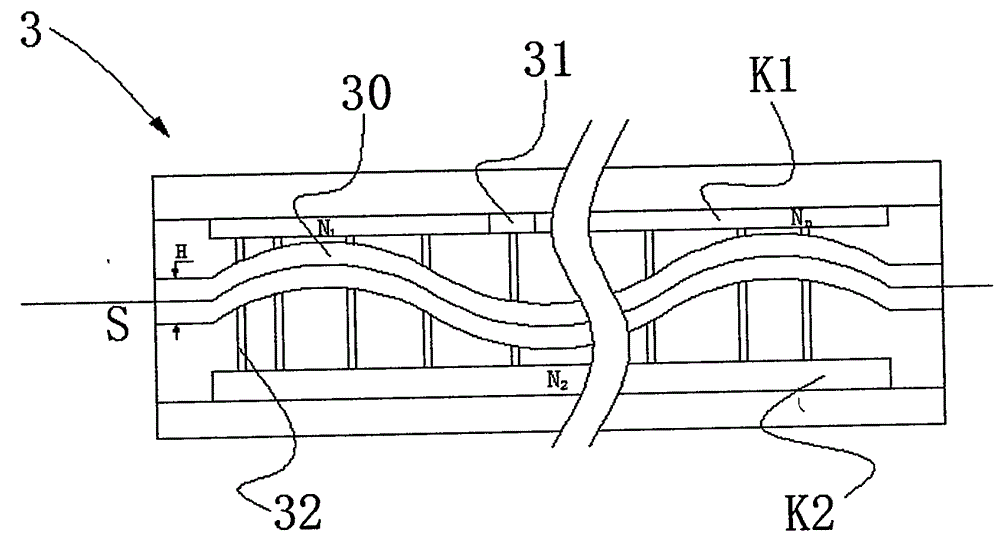

[0042] Step 2, the continuous fiber processed by the untwisting machine is sent to several curved / straight dipping passages 30 of the dipping mold 3 through the tractor, here, there are 8 yarn bobbins coming out through the creel, and the dipping passages of the dipping mold It needs to match.

[0043] Step 3, the material processed by the screw extruder 7 is transp...

Embodiment 2

[0066] Embodiment 2: the method for manufacturing continuous fiber reinforced material, this method comprises the following steps: make the continuous fiber on the creel 1 be drawn to the untwisting machine 2 by the traction machine 4, eight yarn bobbins are installed on the creel , continuous fiber includes but not limited to glass fiber, basalt fiber, boron fiber, silicon carbide fiber, copper fiber, stainless steel fiber, iron fiber, nickel fiber; In the linear impregnation passage 30 (four impregnation passages are shown in the figure); the material processed by the screw extruder 7 is transported to the resin mixture inlet 31 of the impregnation mold through the melt pump 6, where the screw extruder is added The materials discharged from the machine include thermoplastic resin, plastic additive, and surface treatment agent, and the addition ratio of thermoplastic resin, plastic additive, and surface treatment agent is related to the weight of the continuous fiber. The weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com