Composite corrosion/scale inhibitor for circulating cooling water treatment

A technology of circulating cooling water and corrosion and scale inhibitors, applied in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc., to achieve excellent scale inhibition effect and environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0013] Based on the total weight of the antiscalant, mix and stir 15% polyepoxysuccinate sodium PESA, 15% polyaspartate sodium PASP, 20% acrylic acid-2-acrylamido-2-methylpropanesulfonic acid copolymer AA-AMPS, 15% hydrolyzed polymaleic anhydride HPMA and the rest deionized water are used to prepare the composite corrosion and scale inhibitor for circulating cooling water treatment of the present invention.

Embodiment

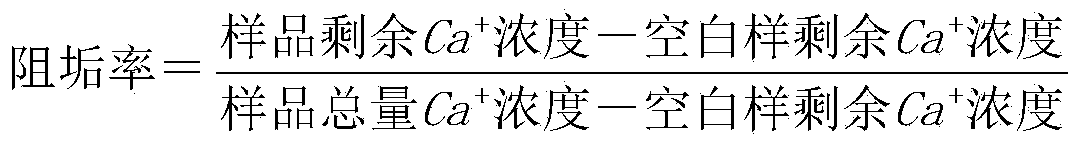

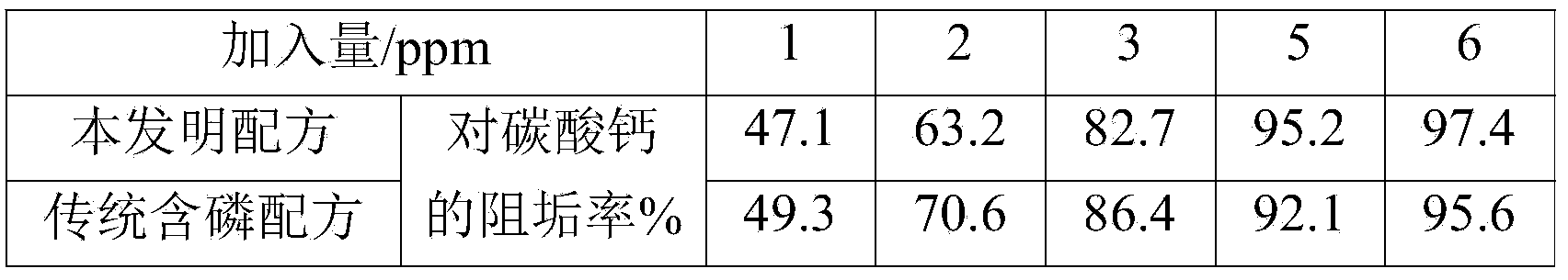

[0015] The scale inhibitor of the present invention and the traditional phosphorus-containing formula prepared in the above preparation examples were respectively used, wherein the traditional phosphorus-containing scale inhibitor used was AX- 322, treat conventional industrial circulating cooling water with different additions, and measure and calculate the scale inhibition rate of calcium carbonate according to the static method, as follows:

[0016] (1) Put conventional industrial circulating cooling water (hereinafter referred to as test water) into a 1000ml beaker, and add water treatment agents of different formulations according to the following different dosages.

[0017] (2) Put the beaker with test water into a water bath, keep the temperature at 80°C, and concentrate according to the concentration ratio required by the actual operating conditions, generally 2.5-4 times. At the same time do a blank test.

[0018] (3) During the waiting process of concentration, meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com