Low-density high-effect ceramic granule and preparation method thereof

A high-efficiency, low-density technology, applied in the field of petroleum proppants, can solve the problems of reduced ceramsite resistance to crushing, and achieve the effects of easy implementation, easy availability, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

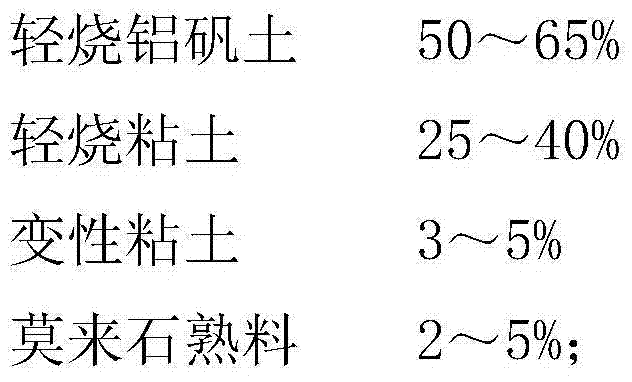

[0026] Low-density high-efficiency ceramsite, its raw material composition is as follows:

[0027] Lightly burned bauxite (mass percentage of aluminum is 55.8%) 1800g, lightly burned clay (mass percentage of aluminum is 47.2%) 1020g, modified clay 90g, mullite clinker 90g, modified starch (additional group points) 60g.

[0028] The preparation steps are as follows:

[0029] After the raw materials are prepared in proportion, they are ground by a ball mill to make the powder fineness reach 600 mesh and the pass rate is over 90%;

[0030] After granulation, dry ceramsite semi-finished products at 150°C;

[0031] Qualified ceramsite semi-finished products are obtained by sieving, and fired at a high temperature of 1430°C to obtain finished ceramsite.

[0032] The ceramsite 20 / 40 mesh bulk density of the finished product is 1.62g / cm 3 , the apparent density is 2.80, the 52MPa breakage rate is 3.52%, and the acid solubility is 4.8%. Example 2

Embodiment 2

[0033] Low-density high-efficiency ceramsite, its raw material composition is as follows:

[0034] Lightly burned bauxite (mass percentage of aluminum is 58.9%) 1920g, lightly burned clay (mass percentage of aluminum is 47.2%) 900g, denatured clay 90g, mullite clinker 90g, modified starch (additional group points) 60g.

[0035] The preparation steps are as follows:

[0036] After the raw materials are prepared in proportion, they are ground by a ball mill to make the powder fineness reach 600 mesh, and the pass rate is above 90%;

[0037] After granulation, dry ceramsite semi-finished products at 180°C;

[0038] Qualified ceramsite semi-finished products are obtained by screening, and fired at a high temperature of 1420°C to obtain finished ceramsite.

[0039] The ceramsite 20 / 40 mesh bulk density of the finished product is 1.60g / cm 3 , The apparent density is 2.92, the 52MPa breakage rate is 3.9%, and the acid solubility is 5.2%.

Embodiment 3

[0041] Low-density high-efficiency ceramsite, its raw material composition is as follows:

[0042] Lightly burned bauxite (mass percentage composition of aluminum is 59.1%) 1560g, lightly burned clay (mass percentage composition of aluminum is 47.2%) 1200g, denatured clay 90g, mullite clinker 150g, modified starch (additional composition points) 60g.

[0043] The preparation steps are as follows:

[0044] After the raw materials are prepared in proportion, they are ground by a ball mill to make the powder fineness reach 600 mesh and the pass rate is over 90%;

[0045] After granulation, dry ceramsite semi-finished products at 220°C;

[0046] Qualified ceramsite semi-finished products are obtained by screening, and fired at a high temperature of 1440°C to obtain finished ceramsite.

[0047] The ceramsite 20 / 40 mesh bulk density of the finished product is 1.60g / cm 3 , the apparent density is 2.92, the 52MPa breakage rate is 3.42%, and the acid solubility is 4.96%.

[0048] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com