Preparation method of levo cloperastine fendizoate

A technology of leverastimine and cloperastine, applied in the field of chemical drug synthesis, can solve the problems of low total yield in the preparation process, and achieve the effects of reducing three waste pollution, simple operation and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

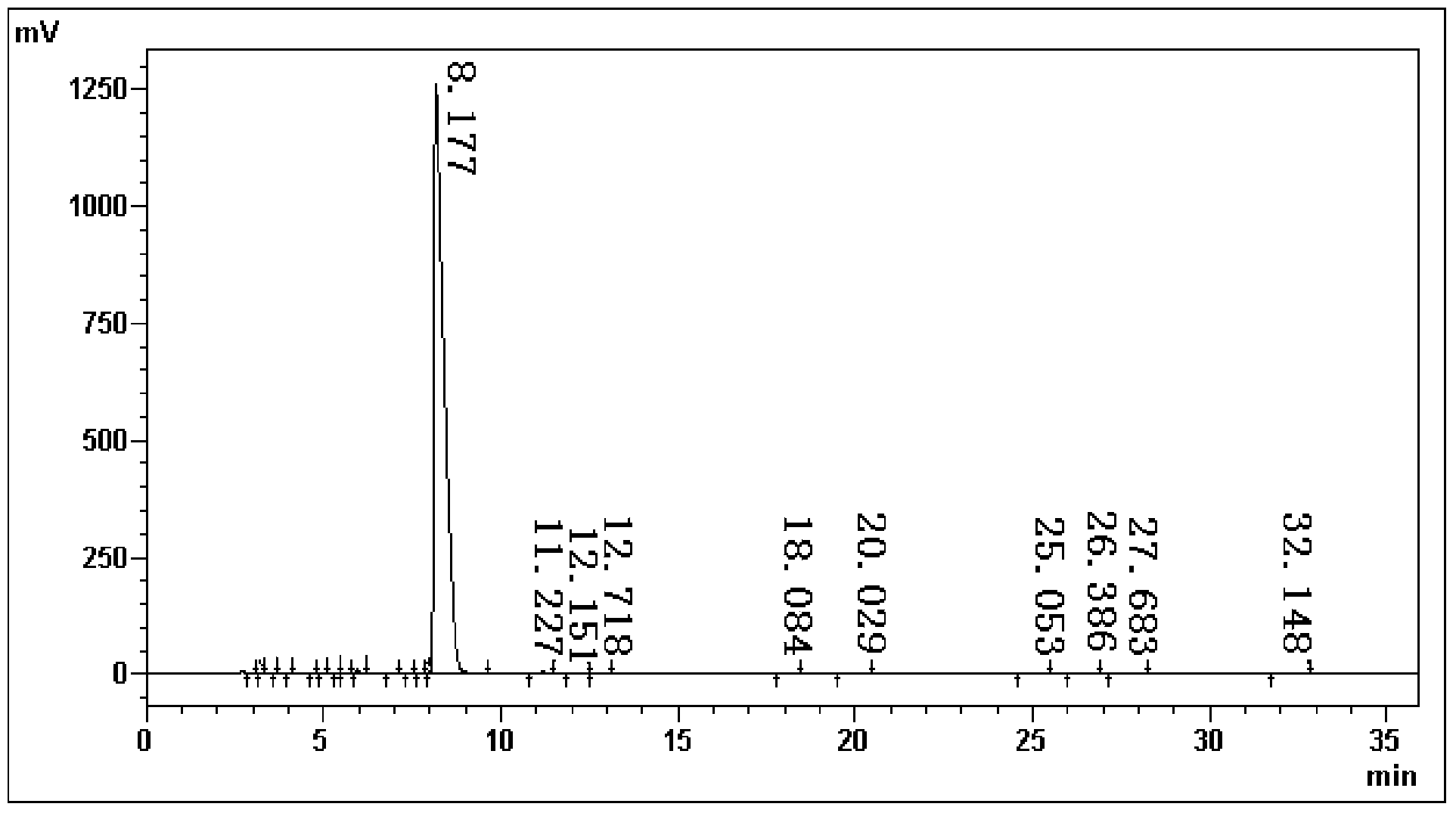

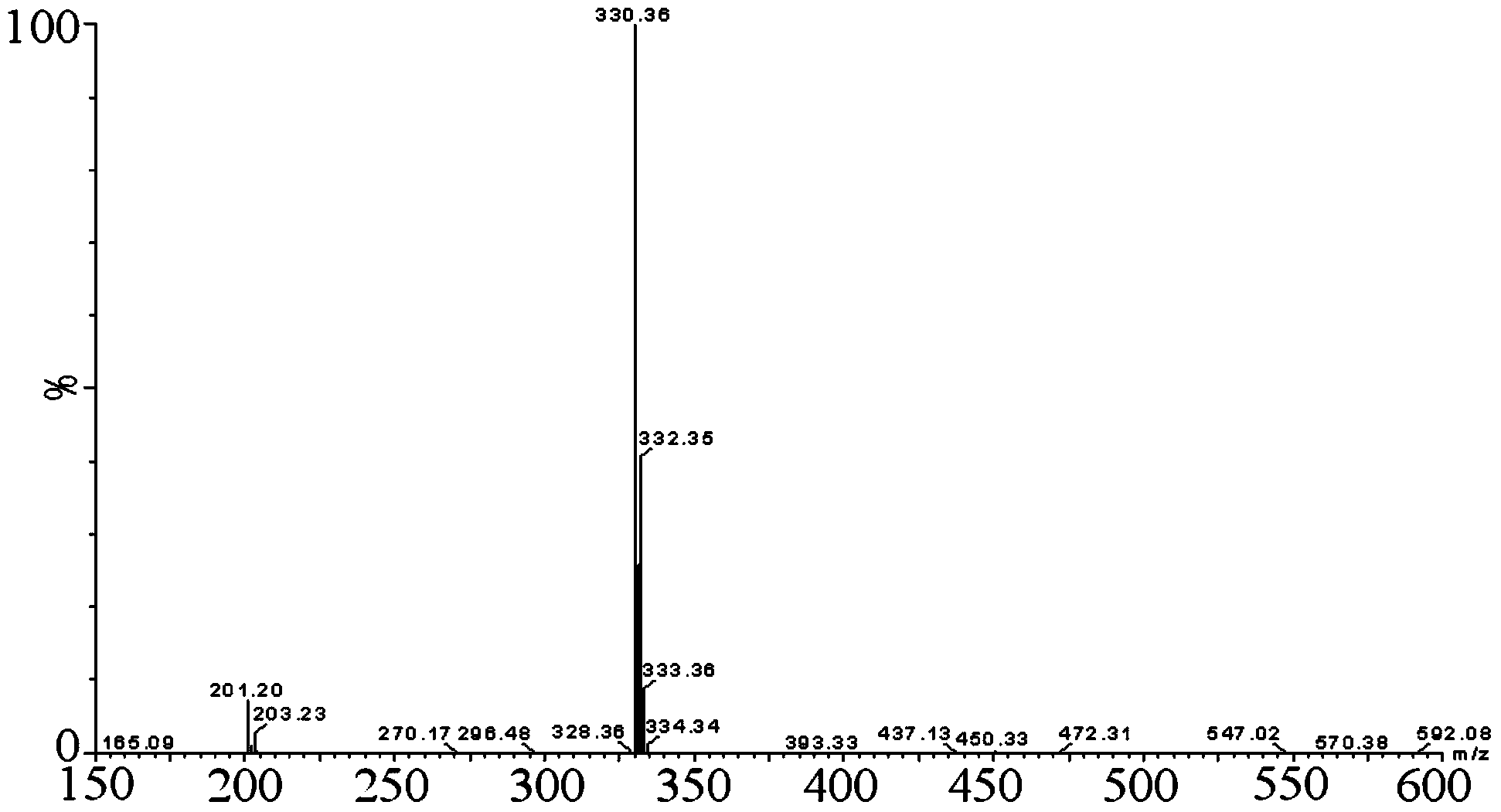

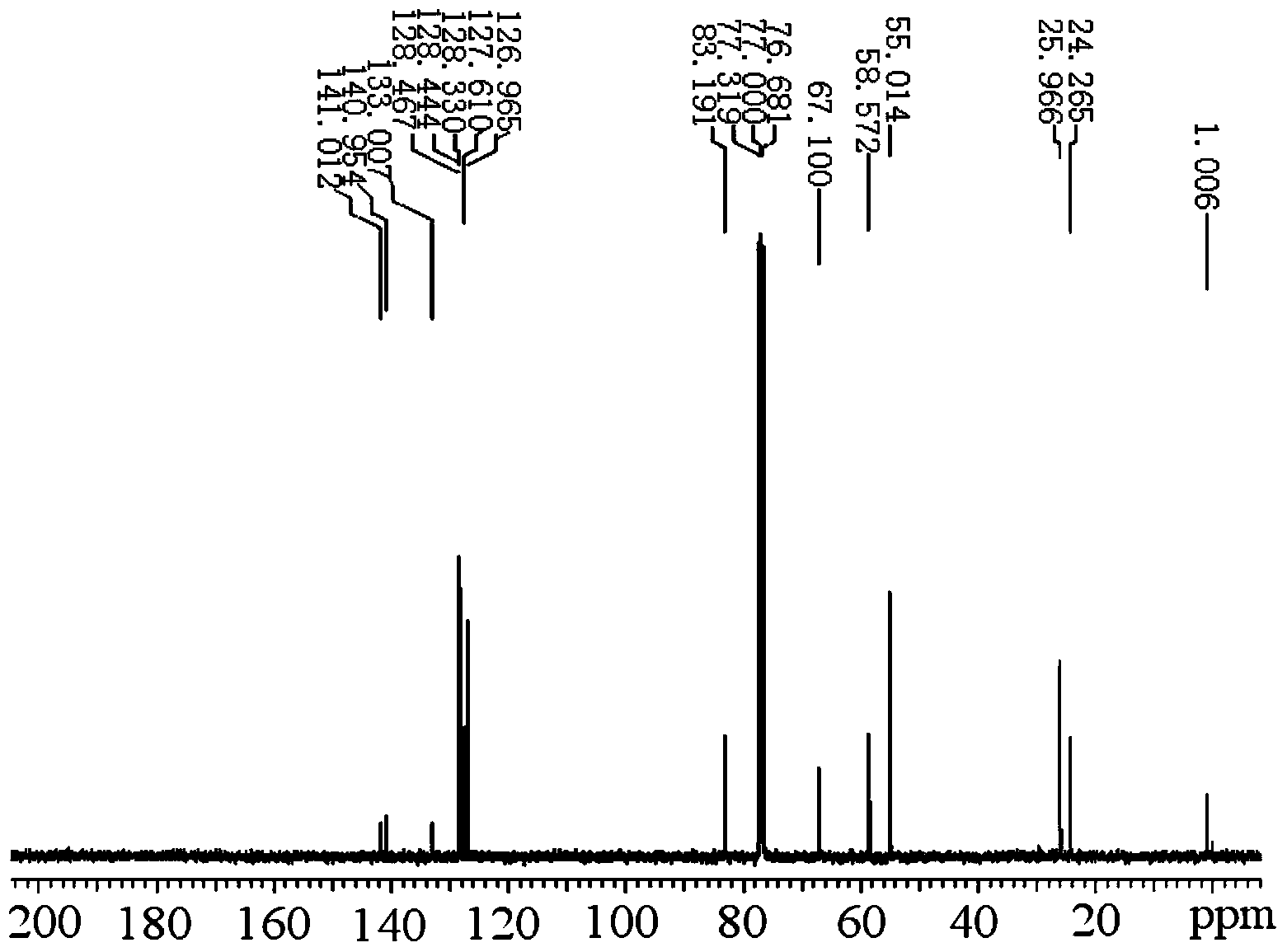

Image

Examples

preparation example Construction

[0037] The present invention provides a method for preparing L-cloperastine fendizoic acid, which comprises the following steps:

[0038] Using a resolving agent to resolve racemic cloperastine in a fatty alcohol solvent to obtain L-cloperastine, the resolving agent is L-(-)-diR substituted benzoyl tartaric acid, and the R Is alkyl, alkoxy, -Cl, -F, -Br or -H;

[0039] The L-cloperastine and Fendizic acid are reacted in salt formation to obtain the L-cloperastine Fendizic acid.

[0040] The method provided by the present invention uses L-(-)-diR substituted benzoyltartaric acid as a resolving agent to resolve racemic cloperastine in a fatty alcohol solvent. The resolution yield is high, so that L-cloperastine fendizoic acid has high optical purity and high product yield.

[0041] In addition, the resolving agent and fatty alcohol solvent used in the resolution of racemic cloperastine in the present invention can be repeatedly used, which reduces the cost and reduces the pollution of ...

Embodiment 1

[0113] Into a dry and clean 1000mL three-necked reaction flask, add 300g (1.373mol) 4-chlorobenzyl alcohol, 150g (1.863mol) 2-chloroethanol and 350mL toluene in sequence, stir to dissolve;

[0114] Slowly add 50g of concentrated sulfuric acid dropwise to the solution obtained by dissolving, heating to reflux at a heating rate of 4°C / min, and reacting for 5 hours;

[0115] Cool the obtained reaction product to room temperature, add 100 mL of water to it for extraction, neutralize it with a 42% mass concentration of liquid caustic soda until the pH of the water layer reaches 7, and then separate the water layer;

[0116] The organic layer was distilled under reduced pressure to recover toluene, distilled to an internal temperature of 120° C., and a vacuum of -0.08 MPa or more, to obtain 390 g of oil.

[0117] Put the above-mentioned 390g oily substance into a 2000mL dry and clean three-necked reaction flask, add 150g anhydrous sodium carbonate and 180g (2.118mol) piperidine to it, and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com