Self-crosslinked expansion flame-retardant material and preparation method thereof

An intumescent flame retardant and self-crosslinking technology, applied in the field of self-crosslinking intumescent flame retardant materials and their preparation, can solve the problems of low comprehensive performance and harsh environmental requirements, and achieve short crosslinking time, excellent flame retardant performance, and water resistance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

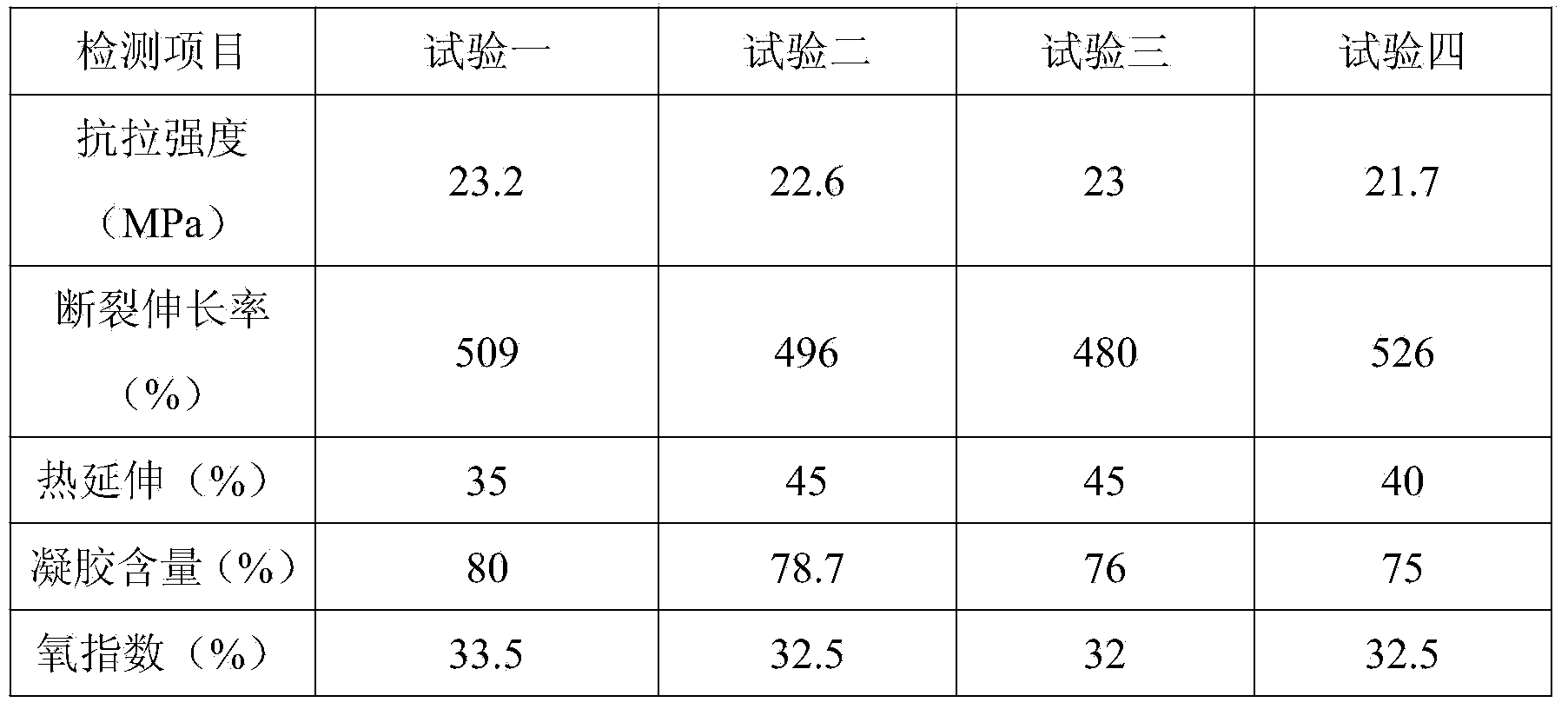

Examples

specific Embodiment approach 1

[0032] Specific embodiment 1: In this embodiment, a self-crosslinking intumescent flame-retardant material is made of 94-96 parts of material A, 2-4 parts of material B and 1-3 parts of material C in parts by weight;

[0033] The A material consists of 100 parts by weight of flame retardant resin, 0.9 to 5 parts of silane coupling agent, 0.09 to 5 parts of initiator, 0.01 to 0.5 parts of composite antioxidant, 0.001 to 0.05 parts of polymerization inhibitor and 0.1 to 5 parts of Made from 5.0 parts of water generating agent;

[0034] The B material is made of 100 parts by weight of flame retardant resin, 0.01-3 parts of high-efficiency catalyst, 0.2-10 parts of stearic acid and 0.01-0.5 parts of composite antioxidant;

[0035] The C material is made of 100 parts by weight of flame retardant resin, 0.01-5 parts of high-efficiency water-absorbing agent, 0.01-0.5 parts of composite antioxidant, 5-20 parts of photoinitiator and 5-30 parts of cross-linking auxiliary agent ;

[00...

specific Embodiment approach 2

[0049]Specific embodiment two: the difference between this embodiment and specific embodiment one is: the silane coupling agent in the A material is vinyltrimethoxysilane, vinyltriethoxysilane, γ-aminopropyl triethyl Oxysilane, Benzylazinomethyltriethoxysilane, γ-Ethyldiazidopropyltrimethoxysilane, β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane and γ-Methyl One of propyl acrylate trimethoxysilane or a mixture of several of them, mixed in any ratio when it is a mixture; the initiator in the A material is dicumyl peroxide, benzoyl peroxide, peroxide Oxidized tert-butyl benzoate, tert-butyl peroxy-3,5,5-trimethylhexanoate or a mixture of several of them, mixed in any ratio when it is a mixture; the barrier in the A material The polymerizing agent is hydroquinone, p-benzoquinone, p-tert-butylcatechol, N,N-dimethylimide, N,N-dimethylacrylamide, tricresyl phosphate, octyl phosphite, One of triphenyl phosphate and 1,1-diphenyl-2-picrylhydrazine or a mixture of several of them, mixed i...

specific Embodiment approach 3

[0050] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the high-efficiency catalyst in the described B material is dibutyltin dilaurate, dioctyltin dilaurate, bis(dodecylsulfanyl) ) dibutyltin, dimethyltinmercaptide, dibutyltinmaleate or dioctyltinmercaptide. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com