Cold-resistant waterproof material

A waterproof material and cold-resistant technology, which is applied in the field of cold-resistant waterproof materials and waterproof materials, can solve problems that affect building quality and service life, weak self-protection, low strength, etc., achieve long service life, avoid object oxidation, and resist cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

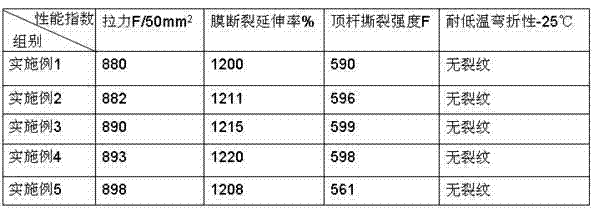

Examples

Embodiment 1

[0014] A cold-resistant waterproof material, comprising the following raw materials in parts by weight: 20 parts of polyurethane, 10 parts of triethanolamine, 5 parts of acrylic resin, 1 part of iron oxide red, 2 parts of titanium dioxide, 0.5 parts of carbon black, gas phase dioxide 1.5 parts of silicon, 1 part of talc powder, 2 parts of expanded perlite, 1 part of tourmaline powder, 0.5 parts of scaly aluminum flakes, 1.5 parts of magnesium oxide, and 15 parts of deionized water.

Embodiment 2

[0016] A cold-resistant waterproof material, comprising the following raw materials in parts by weight: 30 parts of polyurethane, 20 parts of triethanolamine, 10 parts of acrylic resin, 3 parts of iron oxide red, 3 parts of titanium dioxide, 1.2 parts of carbon black, gas phase dioxide 3.6 parts of silicon, 5 parts of talc powder, 7 parts of expanded perlite, 1 part of tourmaline powder, 1 part of scaly aluminum flakes, 4 parts of magnesium oxide, and 30 parts of deionized water.

Embodiment 3

[0018] A cold-resistant waterproof material, comprising the following raw materials in parts by weight: 22 parts of polyurethane, 13 parts of triethanolamine, 7 parts of acrylic resin, 2 parts of iron oxide red, 2 parts of titanium dioxide, 1 part of carbon black, gas phase dioxide 3 parts of silicon, 2 parts of talc powder, 3 parts of expanded perlite, 1 part of tourmaline powder, 0.5 parts of scaly aluminum flakes, 2 parts of magnesium oxide, and 19 parts of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com