Clean fracturing fluid for coal bed fracturing

A clean fracturing fluid and fracturing technology, applied in the direction of drilling composition, production fluid, wellbore/well components, etc., can solve the problems of poor shear resistance, complex configuration, poor water solubility, etc., and reach the reservoir Small damage, low friction, good gel breaking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

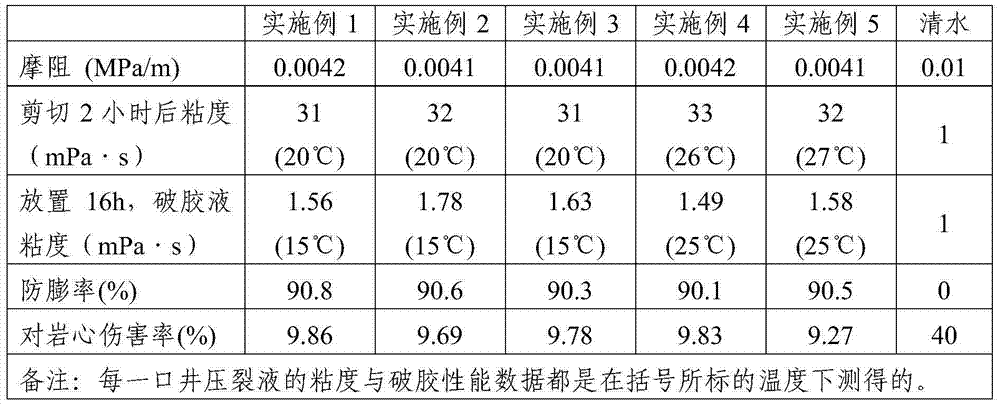

Examples

Embodiment 1

[0038] The clean fracturing fluid of this example was used to perform fracturing reconstruction on the No. 3 coal seam of the Permian Shanxi Formation in Well 2701-36. The well section was 544.76-550.83m, the thickness was 6.07m, the temperature was 15°C, and the fracturing displacement was 4.5m 3 / min, add sand 60m 3 , the average sand ratio is 26%, and the highest sand ratio reaches 45%; pumping after compression for production, the daily gas production is 680m 3 , the gas production is more than double that of the active water fracturing well (the same layer adjacent to the well).

[0039](1) Fracturing fluid formula: 0.6% thickener (a mixture of dimethyl octadecyl hydroxyethyl quaternary ammonium nitrate and sodium salicylate) + 1% ammonium chloride + 0.05% octylphenol ether OP- 10+98.35% water.

[0040] (2) Preparation and use method:

[0041] ①Preparation of thickener (according to the preparation of 1000 parts): add 150 parts of water and 150 parts of sodium salicyla...

Embodiment 2

[0044] The clean fracturing fluid of this example was used to perform fracturing reconstruction on the No. 3 coal seam of the Permian Shanxi Formation in Well 2701-37. The well section was 564.95-570.29m, the thickness was 5.34m, the temperature was 16°C, and the fracturing displacement was 4.5m 3 / min, add sand 60m 3 , the average sand ratio is 25.6%, and the highest sand ratio reaches 45%; pumping after compression for production, the daily gas production is 650m 3 , the gas production is more than double that of the active water fracturing well (the same layer adjacent to the well).

[0045] (1) Fracturing fluid formula: 0.8% thickener (a mixture of dimethyl octadecyl hydroxyethyl quaternary ammonium nitrate and sodium salicylate) + 1% ammonium chloride + 0.05% octylphenol ether OP- 10+98.1% water.

[0046] (2) Preparation and use method:

[0047] ①Preparation of thickener (take the preparation of 1000 parts as an example): add 150 parts of water and 150 parts of sodium ...

Embodiment 3

[0050] The clean fracturing fluid of this example was used to perform fracturing reconstruction on the No. 3 coal seam of the Permian Shanxi Formation in Well 2701-33. The well section was 559.14-564.47m, the thickness was 5.33m, the temperature was 16°C, and the fracturing displacement was 4.5m 3 / min, add sand 60m 3 , the average sand ratio is 26.3%, and the highest sand ratio reaches 45%; pumping after compression for production, the daily gas production is 660m 3 , the gas production is more than double that of the active water fracturing well (the same layer adjacent to the well).

[0051] (1) Fracturing fluid formula: 0.8% thickener (a mixture of dimethyl octadecyl hydroxyethyl quaternary ammonium nitrate and sodium salicylate) + 1% ammonium chloride + 0.1% octylphenol ether OP- 10+98.1% water.

[0052] (2) Preparation and use method:

[0053] ①Preparation of thickener (take the preparation of 1000 parts as an example): add 150 parts of water and 150 parts of sodium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com