Method for pasting soft medium microwave circuits by metal pressure block splicing technology

A microwave circuit and metal technology, which is applied in the direction of circuits, electrical components, waveguide devices, etc., can solve problems such as voids and shorten product production cycles, and achieve the effects of increasing reliability, shortening production cycles, and reducing design types and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

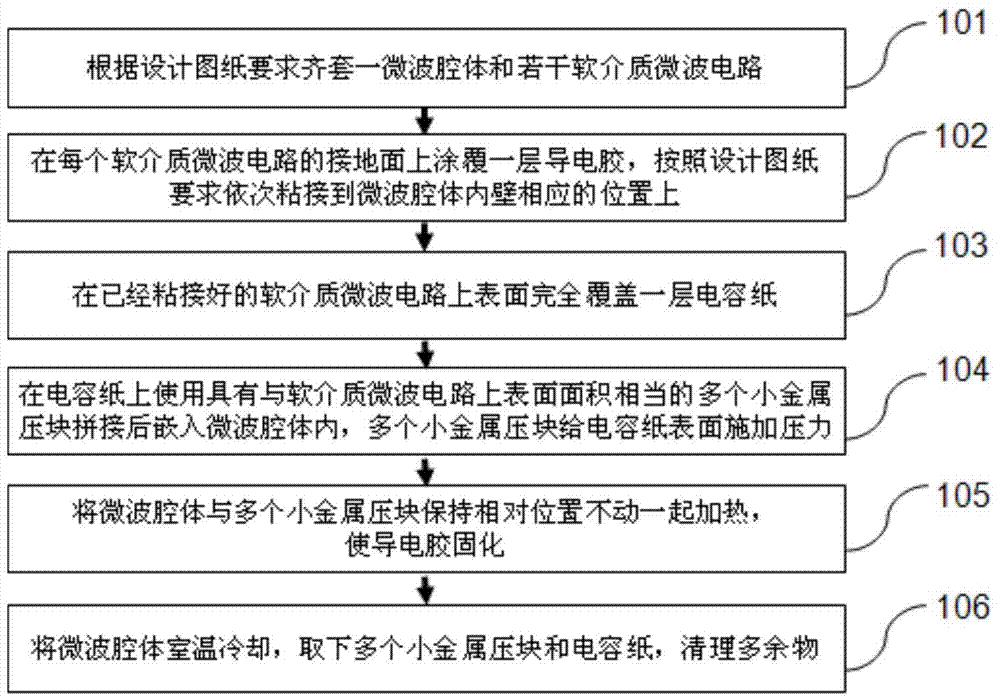

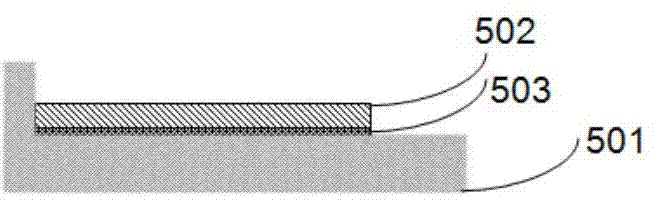

[0029] Such as figure 1 As shown, in the aluminum alloy cavity coated with Ni / Au, paste RT / duroid 5880 soft dielectric microwave circuit, the upper surface of the circuit is the circuit pattern, the lower surface is the ground plane, the thickness of the circuit medium is 0.127mm, and H20E conductive adhesive is used It is bonded to the inner wall of the cavity. During the process, a plurality of copper-based small metal briquettes are spliced into a combined briquette to apply pressure to the soft dielectric microwave circuit.

[0030] 1. Set up a microwave cavity and several soft dielectric microwave circuits according to the requirements of the design drawings;

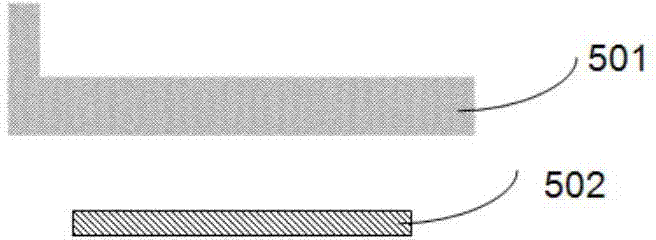

[0031] Such as diagram 2-1 As shown, a microwave cavity 501 and a number of soft dielectric microwave circuits 502 with a thickness of 0.127 mm are assembled according to the requirements of the design drawings, cleaned with absolute ethanol cotton balls, and dried naturally. The inner wall of the microwave ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com