Device for diluting concentrated solution and method

A technology of diluting device and concentrated solution, applied in chemical instruments and methods, mixing methods, dissolving and other directions, can solve the problems of difficult glue with high viscosity, inaccurate concentration, long time, etc., and achieve the effect of reducing the floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

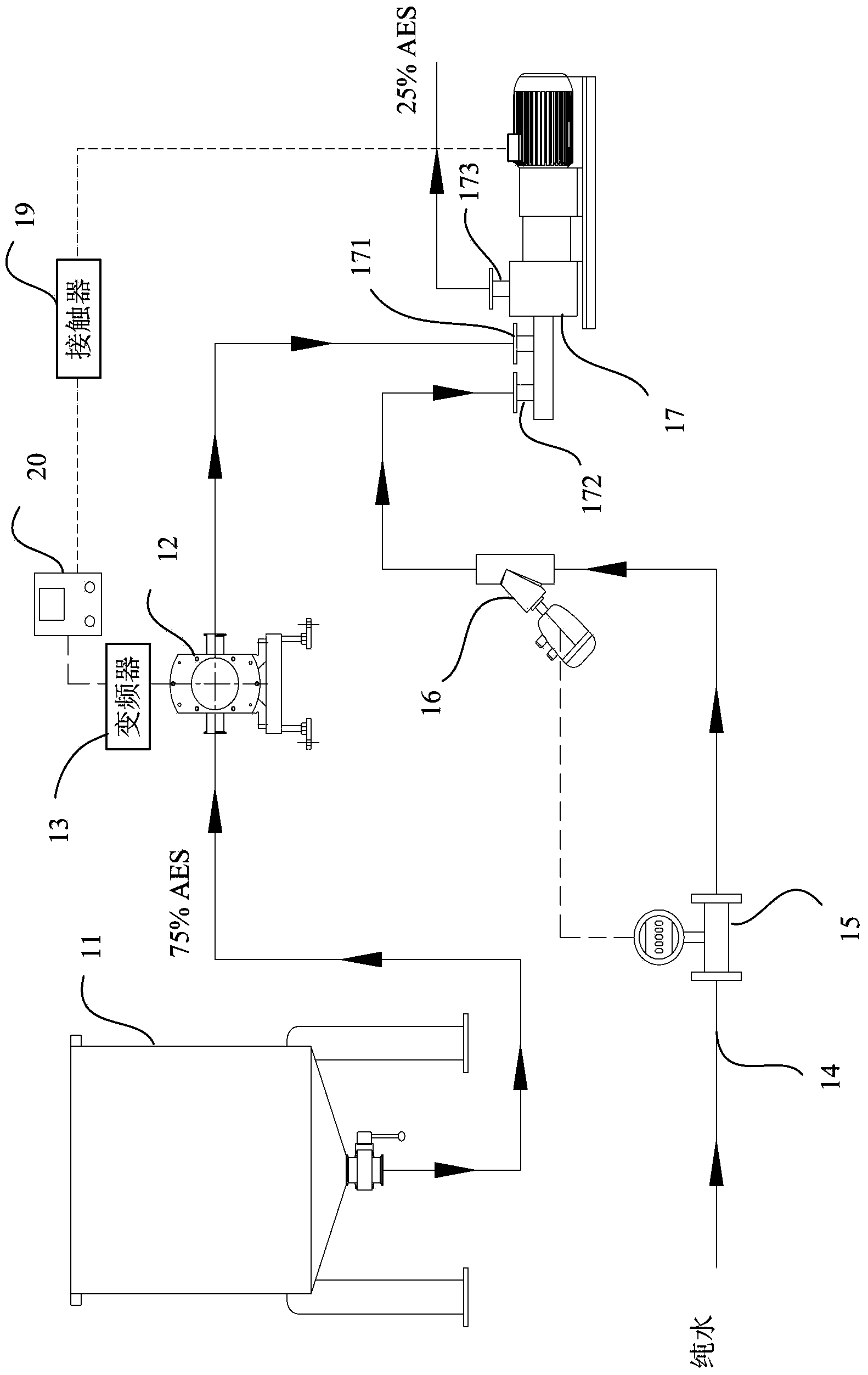

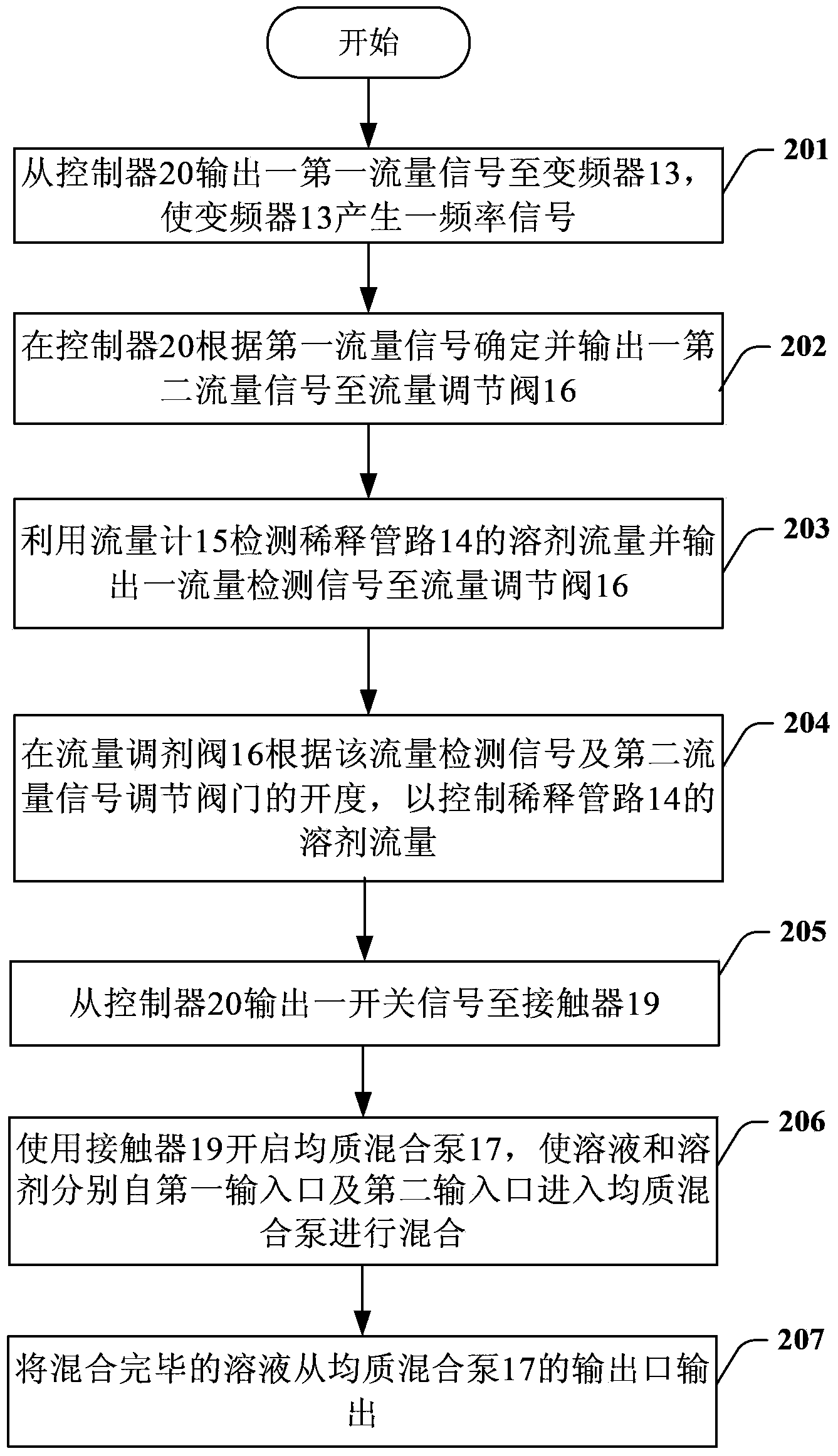

[0038] figure 1 A structural diagram of a concentrated solution diluting device according to an embodiment of the present invention is shown. refer to figure 1 As shown, the concentrated solution dilution device 10 may include a first storage tank 11, a rotor pump 12, a frequency converter 13, a dilution pipeline 14, a flow meter 15, a flow regulating valve 16, a homogeneous mixing pump 17, a contactor 19 and a control device 20. The first storage tank 11 is used to store the solution to be diluted, such as AES commonly used in the daily chemical industry. This solution is usually a higher concentration, for example up to 75% concentrated solution. The capacity of the first storage tank 11 can reach 1.5T.

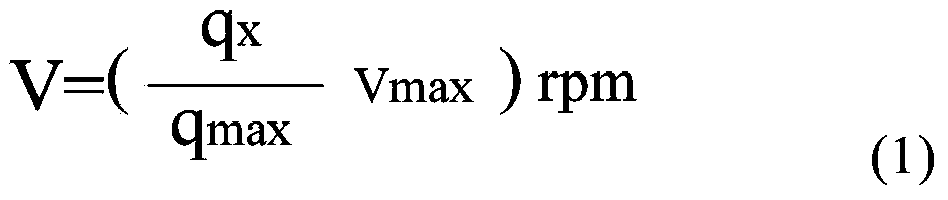

[0039] The rotor pump 12 is connected to the first storage tank 11 through a pipeline. The frequency converter 13 is electrically connected to the rotor pump 12 . The frequency converter 13 outputs a frequency signal to the rotor pump 12 according to a first flow sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com