Fully automatic pressing production line for large steam turbine blades

A steam turbine blade, fully automatic technology, applied in the field of hydraulic machinery, can solve problems such as the inability to meet high production efficiency operating costs, the harsh working environment of operators, and the inability of workers to work for a long time, so as to meet the needs of modern production and ensure machining performance requirements. , the effect of easy maintenance of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0044] It should be noted that, unless otherwise specified and limited, terms such as "first" and "second" do not represent sequential installation, nor do they represent the importance of the described components.

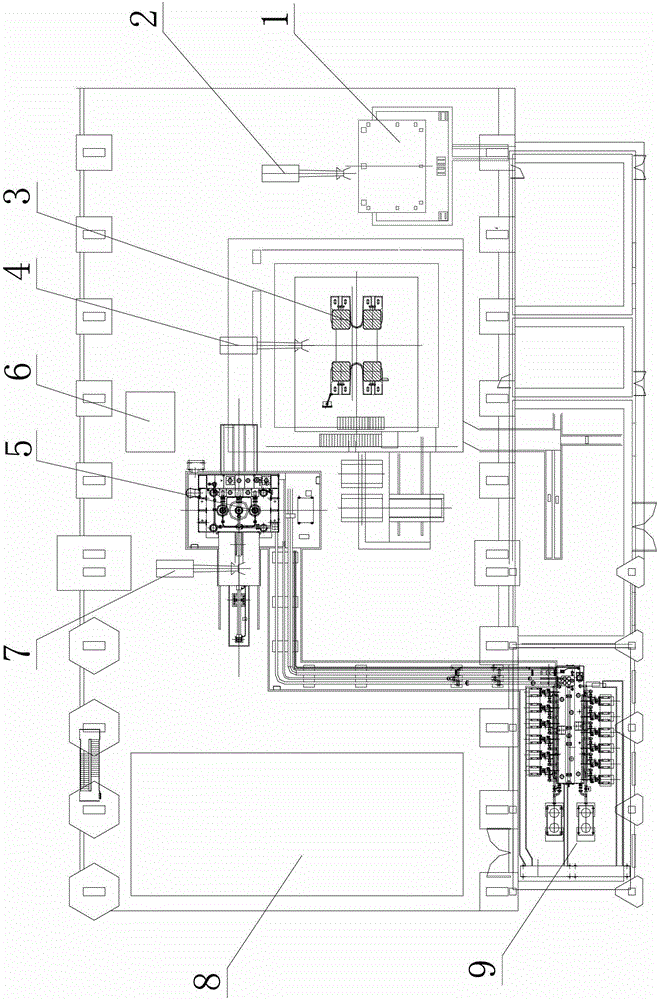

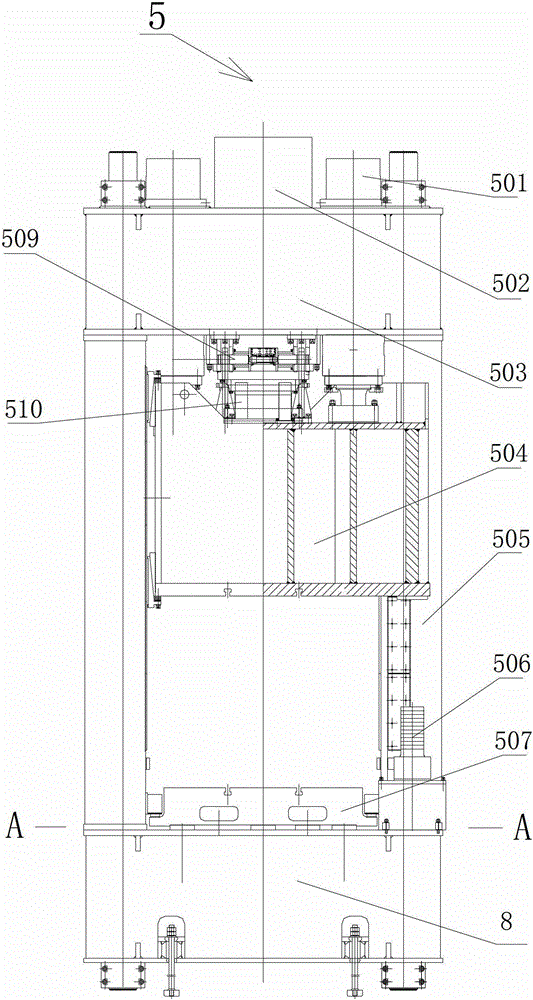

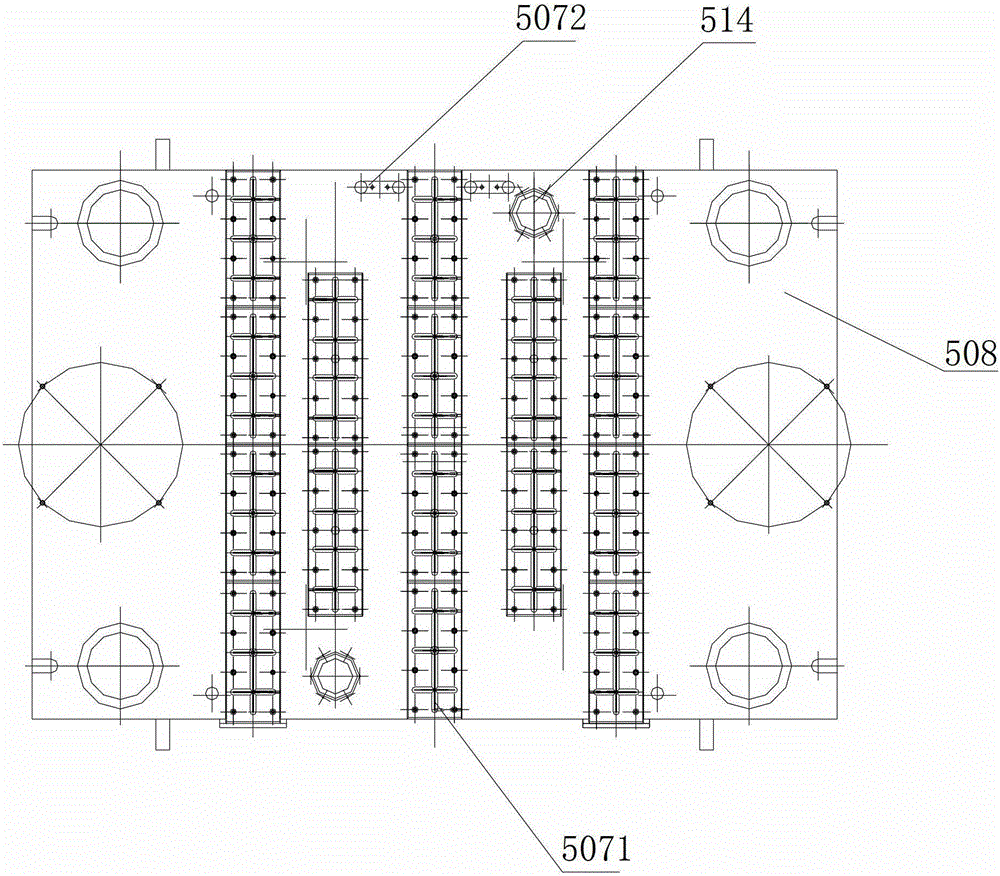

[0045] see figure 1 , large-scale steam turbine blade automatic pressing production line, including gas heating furnace 1, multiple operating manipulators, blade initial forming hydraulic press 3, blade shaping and trimming hydraulic press 5, workpiece flash waste collection device, finished product storage device and blade shaping and trimming hydraulic machine power system9. The gas heating furnace is located on one side of the steam turbine blade initial forming hydraulic press, and the other side of the gas heating furnace i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com