Alkali-free surface active agent for displacing oil and preparation method thereof

A surfactant and oil displacement technology, which is applied in the field of alkali-free surfactant for oil displacement and its preparation, can solve the problems of alkali damage to formation in ASP flooding, and achieve non-toxic and harmless products and good stability. , the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

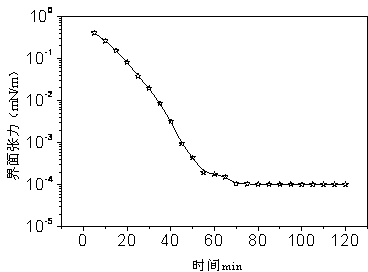

Image

Examples

Embodiment 1

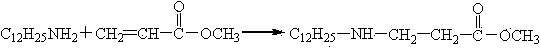

[0026] (1) Add 1 mol of dodecylamine to a four-neck flask, heat to a molten state, slowly add 1.1 mol of methyl acrylate dropwise under mechanical stirring, complete the dropwise addition within 3.5 hours, and react at a constant temperature of 65°C for 4 hours. After completion of the reaction, excess methyl acrylate was distilled off under reduced pressure at 0.03 MPa to obtain methyl dodecylaminopropionate. The yield is 98.5%. The equation is as follows:

[0027]

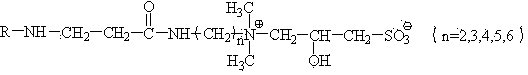

[0028] (2) Add 1 mol of methyl dodecylaminopropionate to a four-neck flask, heat at 90°C until molten, add 1.05 mol of N,N-dimethyl-1,3-propanediamine, and add di React with 5% NaOH methanol solution or KOH methanol solution of the total mass for 1 hour, install a water separator, slowly raise the temperature to 135-150°C, reflux for 5 hours under reduced pressure of 0.03MPa, recover methanol, and consider the reaction until no methanol is formed. At the end point, the mass percentage concentration of NaOH m...

Embodiment 2

[0033] (1) Add 1 mol of aliphatic amine to a four-neck flask, heat to a molten state, slowly add 1.2 mol of methyl acrylate dropwise under mechanical stirring, complete the dropwise addition within 3.5 hours, and react at a constant temperature of 65°C for 4 hours. After the reaction is completed, excess methyl acrylate is distilled off under reduced pressure at 0.03 MPa to obtain methyl aliphatic aminopropionate. The yield is 98%.

[0034] (2) Add 1 mol of aliphatic methyl aminopropionate to a four-necked flask, heat it to a molten state at 90°C, add 1.05 mol of N,N-dimethyl-1,4-butanediamine, and add both React with 5% NaOH methanol solution or KOH methanol solution of the total mass for 1 hour, install a water separator, slowly raise the temperature to 135-150°C, and reflux reaction for 5 hours under reduced pressure of 0.03MPa, recover methanol, until no methanol is formed, it is regarded as the end of the reaction . The yield is 92%.

[0035] (3) Put the quaternization...

Embodiment 3

[0037] (1) Add 1 mol of aliphatic amine to a four-neck flask, heat to a molten state, slowly add 1.1 mol of butyl acrylate dropwise under mechanical stirring, and complete the dropwise addition within 3.5 hours, and react at a constant temperature of 65°C for 4 hours. After the reaction is completed, the excess butyl acrylate is distilled off under reduced pressure at 0.03 MPa to obtain fatty aminopropionate butyl. Yield 97.5%.

[0038](2) Add 1 mol of aliphatic butyl aminopropionate to a four-necked flask, heat it to a molten state at 90°C, add 1.1 mol of N,N-dimethyl-1,5-pentanediamine, and add both React with 5% NaOH methanol solution or KOH methanol solution of the total mass for 1 hour, install a water separator, slowly raise the temperature to 135-150°C, reflux reaction for 5 hours under reduced pressure of 0.03MPa, recover methanol, until no methanol is formed, it is regarded as the end of the reaction . The yield is 91%.

[0039] (3) Put the quaternization reagent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com