Filler processing technology and papermaking technology

A treatment process and pretreatment technology, which is applied in the direction of dyeing polymer organic compound treatment, inorganic compound addition, etc., can solve the problems of shortening the service life of the forming net, wear of the forming net, loss of fillers, etc., and achieve changes in appearance characteristics and retention rate The effect of improving and extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: The filler particles are pretreated according to the ratio of mixing 0.15 kg of polyacrylamide emulsion with 1 ton of filler particles to obtain a mixed emulsion of filler particles, and then the mixed emulsion of filler particles is added to pulp for papermaking .

Embodiment 2

[0025] Example 2: The filler particles are pretreated according to the ratio of 0.5 kg of polyacrylamide emulsion mixed with 1 ton of filler particles to obtain a mixed emulsion of filler particles, and then the mixed emulsion of filler particles is added to pulp for papermaking .

Embodiment 3

[0026] Example 3: The filler particles were pretreated according to the ratio of 1.2 kg of polyacrylamide emulsion mixed with 1 ton of filler particles to obtain a mixed emulsion of filler particles, and then the mixed emulsion of filler particles was added to pulp for papermaking .

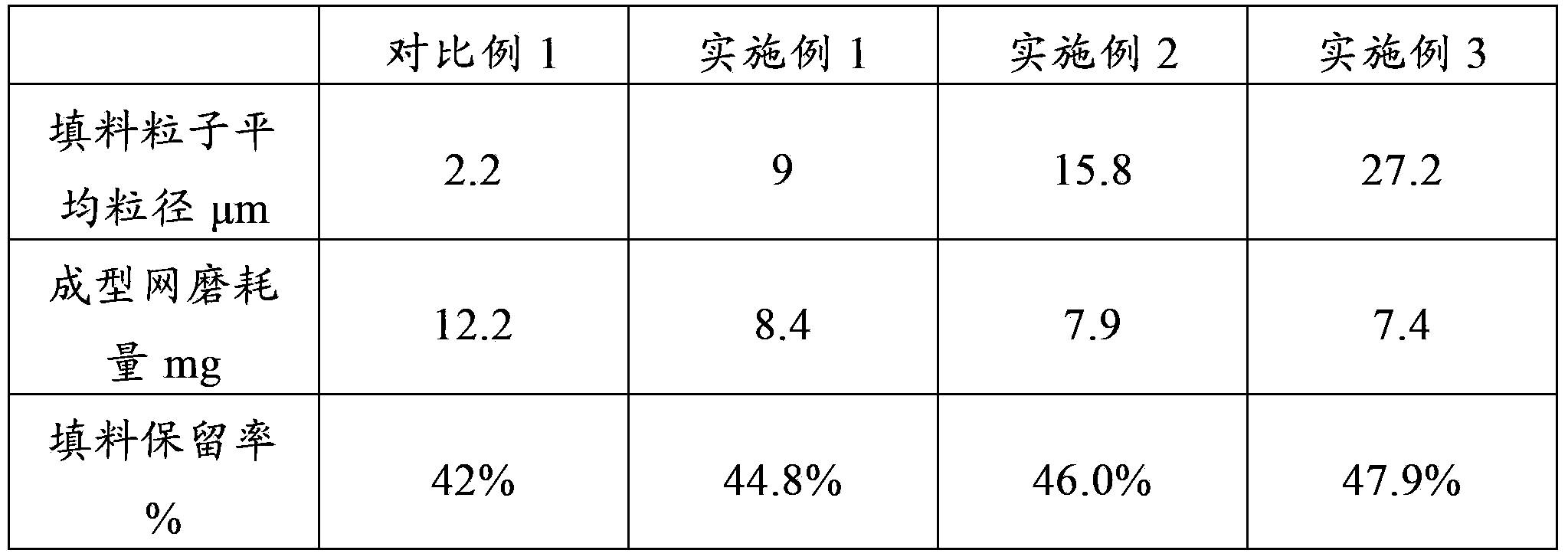

[0027] The experimental data of above-mentioned comparative example and embodiment contrasts the following table:

[0028]

[0029] In this embodiment, the test of the wear amount of the forming wire is carried out by the following method: a quantitative GCC solution is placed in a closed container containing a copper wire and rotated. After 170,000 revolutions, the copper wire is taken out, and the distance before and after the copper wire is measured. Poor quality, which is used to characterize the wear of the forming wire.

[0030] It can be clearly seen from the data in the above table that if the untreated filler is directly used for papermaking, the wear of the paper machine forming wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com