Method for indoor evaluation of cementing quality of cement-formation interface by using ultrasonic waves

A technology for indoor evaluation and cementation quality, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves. It can solve problems such as complicated operations, and achieve the effect of simple operation and good data repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] During the preparation process of the cementing interface cementation model, parameter values are selected according to the influence of parameters such as core permeability, curing temperature, and curing time on the quality of the cementing interface cementation model. It is a routine choice for technicians when preparing the cementing model of the cementing interface.

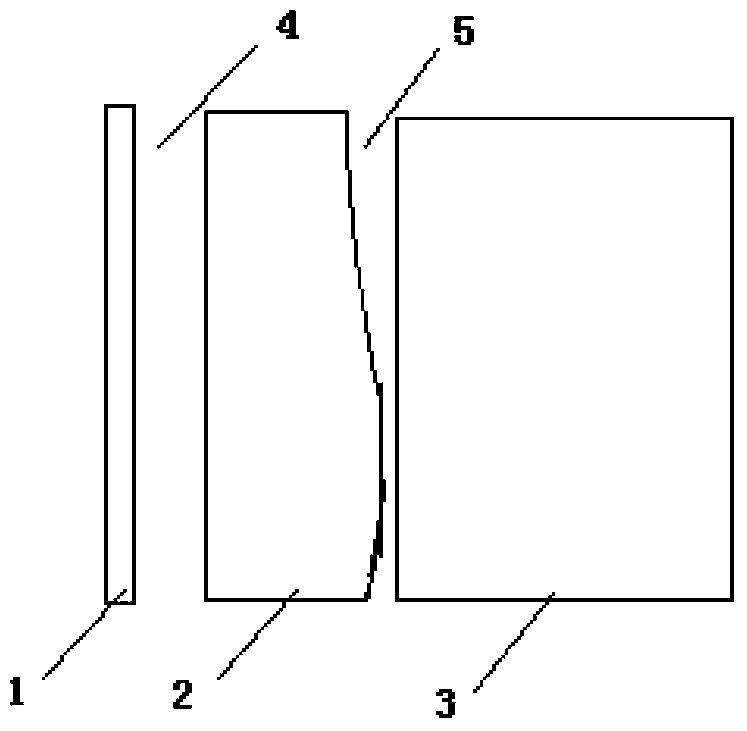

[0045] In the embodiment of the present invention, the artificial core is in the shape of a cylinder, and the cementation model of the two cementing interfaces formed is in the shape of a cube.

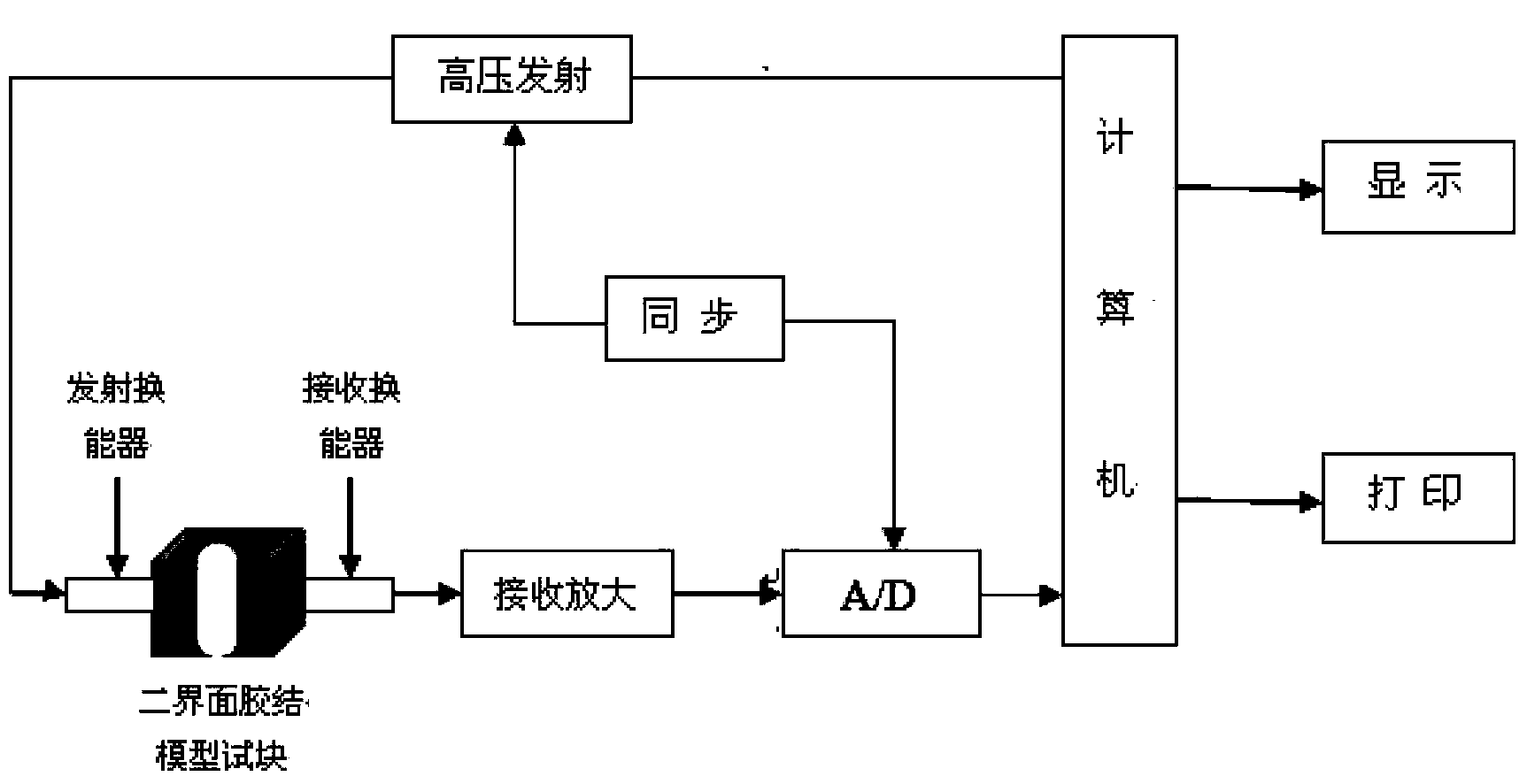

[0046] Step 103, see image 3 , place the cementing model of the cementing interface between the transmitting transducer and the receiving transducer of the ultrasonic instrument. The present invention uses the acoustic wave method to judge the cementing quality of the cementing interface. Therefore, when using an ultrasonic instrument to detect the first wave amplitude and sound velocity of the cementing ...

example

[0067] This embodiment provides a method for indoor evaluation of the bonding quality of the cementing-two interface by using the ultrasonic method.

[0068] This experimental example can be operated according to the following steps:

[0069] In the first step, five cylindrical artificial cores made of quartz sand are selected. The length of the five artificial cores is 50 mm, the diameter is 25 mm, the porosity is 34%, and the permeability is 0.6 Darcy. Number the 5 artificial cores and mark them as 1 # -5 # .

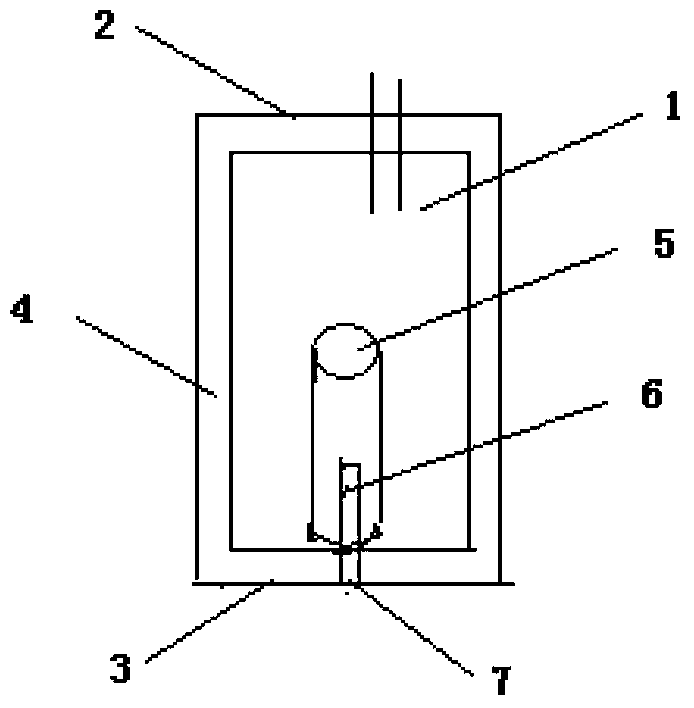

[0070] In the second step, the 1 selected in the first step # -5 # Cylindrical artificial rock cores are put into five high-temperature and high-pressure filter cake forming devices respectively (see figure 2 ), pour the configured drilling fluid (drilling fluid commonly used in the drilling operation in the experimental example of the present invention) into the surroundings of the above-mentioned 5 artificial rock cores respectively, and prepare 5 artificial r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com