Method for improving emulsifying property of isolated soybean protein under acidic condition, and products of isolated soybean protein

A technology of soybean protein isolate and acidic conditions, which is applied in the field of improving the emulsification performance of soybean protein isolate under acidic conditions, can solve the problems of poor emulsification performance and stability, and achieve good emulsification effect, emulsification and emulsification stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 modified soybean protein isolate

[0032] 1. Adjust the moisture content of soybean protein isolate to 25% (kg / L), and set the temperatures of the first to fourth sections of the barrel of the twin-screw extruder to normal temperature, 50°C, 80°C, and 110°C respectively; The hole diameter is 18mm, and the screw speed is 100r / min. The extruded and expanded soybean protein isolate is dried and pulverized and stored for later use.

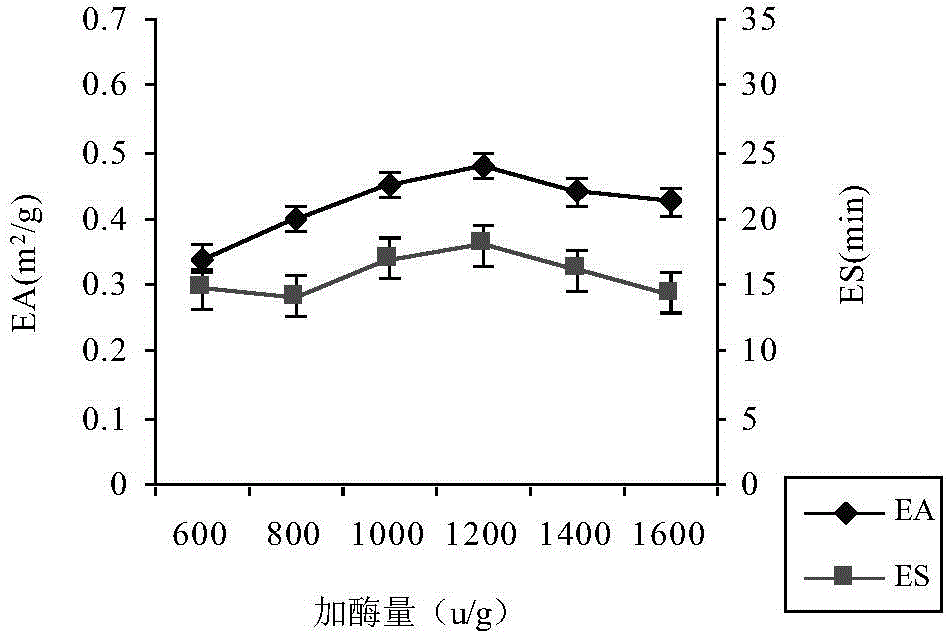

[0033] 2. In terms of mass percentage, the extruded pretreated protein powder is made into an aqueous solution of soybean protein isolate with a concentration of 12%, and bromelain 1600u / g is added, and reacted in a shaking water bath at 55°C for 40min. The pH of the reaction is 7, and then in Inactivate the enzyme in a boiling water bath, cool in cold water, concentrate and dry to obtain the product.

Embodiment 2

[0034] The preparation of embodiment 2 modified soybean protein isolates

[0035] 1. Adjust the moisture content of soybean protein isolate to 20% (kg / L), and set the temperatures of the first to fourth sections of the barrel of the twin-screw extruder to normal temperature, 50°C, 80°C, and 110°C respectively; The hole diameter is 18mm, and the screw speed is 100r / min. The extruded and expanded soybean protein isolate is dried and pulverized and stored for later use.

[0036] 2. In terms of mass percentage, the extruded pretreated protein powder is made into an aqueous solution of soybean protein isolate with a concentration of 2%, and bromelain 600u / g is added, and reacted in a shaking water bath at 55°C for 15min. The pH of the reaction is 7, and then in Inactivate the enzyme in a boiling water bath, cool in cold water, concentrate and dry to obtain the product.

Embodiment 3

[0037] The preparation of embodiment 3 modified soybean protein isolates

[0038]1. Adjust the moisture content of soybean protein isolate to 20% (kg / L), and set the temperatures of the first to fourth sections of the barrel of the twin-screw extruder to normal temperature, 50°C, 80°C, and 110°C respectively; The hole diameter is 18mm, and the screw speed is 100r / min. The extruded and expanded soybean protein isolate is dried and pulverized and stored for later use.

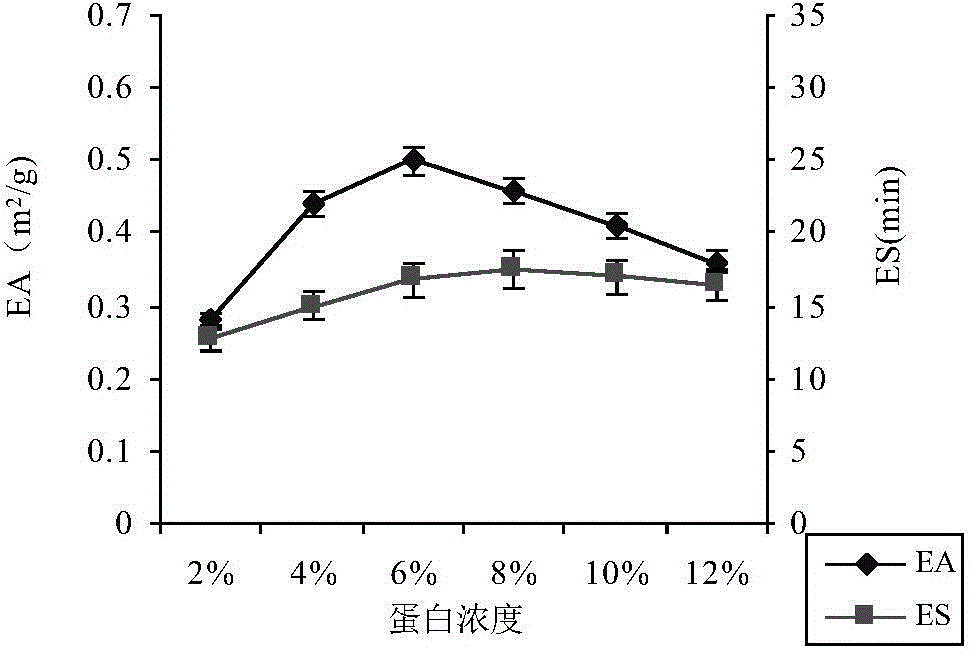

[0039] 2. In terms of mass percentage, the extruded pretreated protein powder is made into an aqueous solution of soybean protein isolate with a concentration of 6%, and bromelain 1200u / g is added, and reacted in a shaking water bath at 55°C for 30min. The pH of the reaction is 7, and then in Inactivate the enzyme in a boiling water bath, cool in cold water, concentrate and dry to obtain the product.

[0040] At pH 4, the emulsifying activity of the prepared modified soybean protein isolate was 0.49m 2 / g, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emulsifying | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com